Advanced robotics is revolutionizing the manufacturing industry by significantly reducing waste and enhancing efficiency. As industries strive to become more sustainable, the integration of robotics into manufacturing processes is proving to be a game-changer. This article explores the various ways in which advanced robotics is contributing to waste reduction and the broader implications for the manufacturing sector.

Understanding Advanced Robotics in Manufacturing

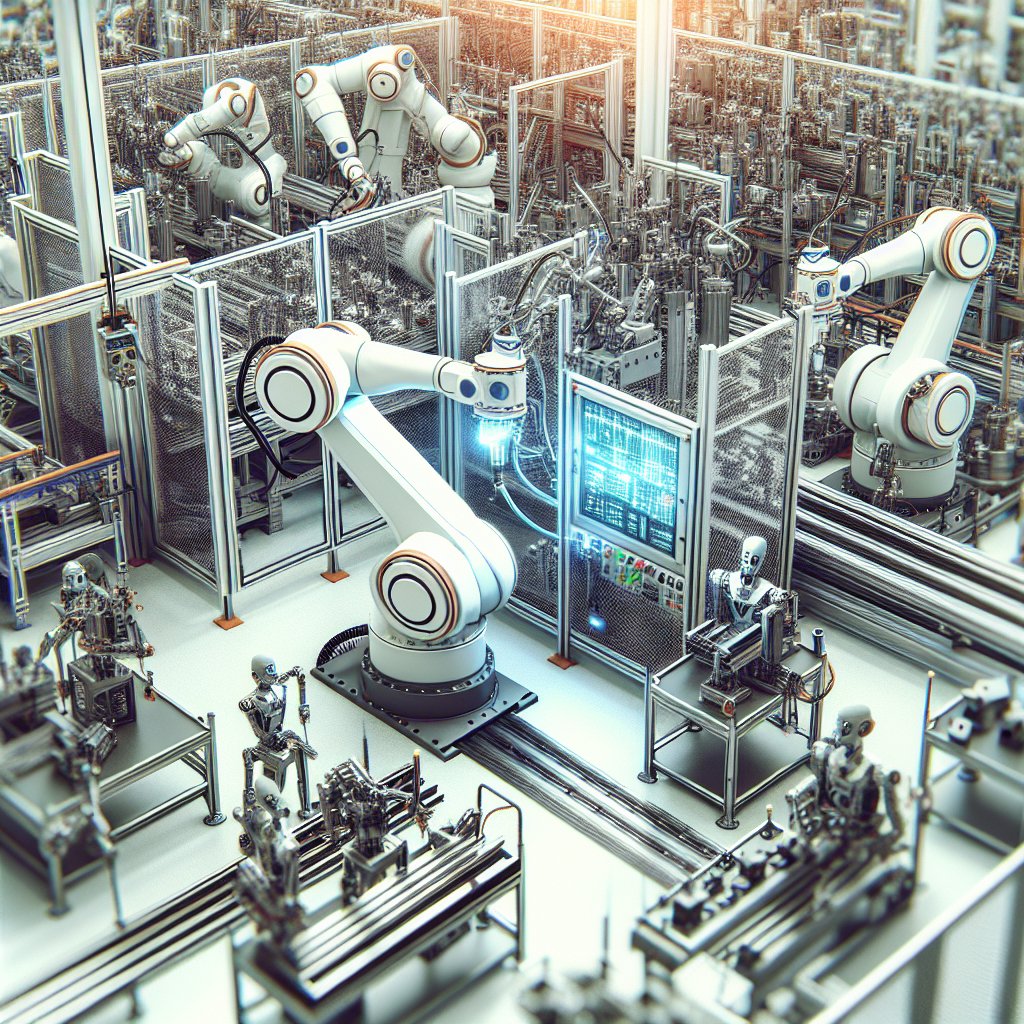

Advanced robotics refers to the use of sophisticated robotic systems that are capable of performing complex tasks with high precision and efficiency. These systems are equipped with cutting-edge technologies such as artificial intelligence, machine learning, and computer vision, enabling them to adapt to dynamic environments and make real-time decisions. In the context of manufacturing, advanced robotics is employed to automate repetitive tasks, enhance production accuracy, and optimize resource utilization.

The integration of advanced robotics in manufacturing processes is not just about replacing human labor with machines. It is about creating a symbiotic relationship where robots and humans work together to achieve greater efficiency and sustainability. By automating mundane and repetitive tasks, robots free up human workers to focus on more strategic and creative aspects of production, leading to a more productive and innovative manufacturing environment.

Reducing Material Waste Through Precision and Efficiency

One of the primary ways advanced robotics reduces waste in manufacturing is through enhanced precision and efficiency. Traditional manufacturing processes often involve a significant amount of material waste due to human error and inefficiencies. Robots, on the other hand, are capable of performing tasks with a level of precision that is difficult for humans to achieve consistently. This precision minimizes material waste by ensuring that each component is produced to exact specifications, reducing the need for rework and scrap.

Moreover, advanced robotics systems are designed to optimize the use of raw materials. Through intelligent algorithms and real-time data analysis, these systems can adjust production parameters to minimize waste. For example, in additive manufacturing, robots can precisely control the deposition of materials, ensuring that only the necessary amount is used for each part. This not only reduces waste but also lowers production costs and environmental impact.

Enhancing Energy Efficiency

In addition to reducing material waste, advanced robotics also contributes to energy efficiency in manufacturing. Robots are designed to operate with minimal energy consumption, and their ability to perform tasks quickly and accurately reduces the overall energy required for production. Furthermore, advanced robotics systems can be programmed to operate during off-peak hours when energy costs are lower, further enhancing energy efficiency.

Energy-efficient manufacturing processes are crucial for reducing the carbon footprint of the industry. By integrating advanced robotics, manufacturers can achieve significant energy savings, contributing to their sustainability goals and reducing their impact on the environment. This is particularly important in industries with high energy demands, such as automotive and aerospace manufacturing, where even small improvements in energy efficiency can lead to substantial environmental benefits.

Improving Quality Control and Reducing Defects

Quality control is a critical aspect of manufacturing, and advanced robotics plays a vital role in enhancing product quality and reducing defects. Robots equipped with advanced sensors and machine vision systems can perform real-time inspections of products during the manufacturing process. This allows for the early detection of defects and deviations from specifications, enabling manufacturers to address issues before they result in waste.

By improving quality control, advanced robotics reduces the need for rework and the production of defective products, both of which contribute to waste. High-quality products also lead to increased customer satisfaction and reduced returns, further minimizing waste in the supply chain. The ability of robots to consistently produce high-quality products is a significant advantage in industries where precision and reliability are paramount.

Facilitating Flexible and Agile Manufacturing

Advanced robotics enables manufacturers to adopt more flexible and agile production processes, which are essential for reducing waste in today’s fast-paced market environment. Traditional manufacturing systems are often rigid and require significant time and resources to reconfigure for new products or changes in demand. In contrast, robotic systems can be easily reprogrammed and reconfigured, allowing manufacturers to quickly adapt to changing market conditions.

This flexibility reduces waste by minimizing downtime and ensuring that production lines are always operating at optimal efficiency. It also allows manufacturers to produce smaller batches of customized products without the waste associated with large-scale production runs. As consumer demand for personalized products continues to grow, the ability to produce customized items efficiently and with minimal waste is becoming increasingly important.

Challenges and Future Prospects

While the benefits of advanced robotics in reducing waste are clear, there are also challenges that manufacturers must address to fully realize these benefits. The initial investment in robotic systems can be significant, and there is a need for skilled personnel to operate and maintain these systems. Additionally, the integration of robotics into existing manufacturing processes requires careful planning and coordination.

Despite these challenges, the future prospects for advanced robotics in manufacturing are promising. As technology continues to evolve, robots are becoming more affordable, versatile, and easier to integrate into production processes. Advances in artificial intelligence and machine learning are also enhancing the capabilities of robotic systems, enabling them to perform increasingly complex tasks with greater autonomy.

In conclusion, advanced robotics is playing a crucial role in reducing waste in manufacturing by enhancing precision, efficiency, and flexibility. As manufacturers continue to seek ways to improve sustainability and reduce their environmental impact, the adoption of advanced robotics is likely to accelerate. By embracing this technology, manufacturers can not only reduce waste but also enhance their competitiveness in the global market.