The History of Steam-Powered Machinery reveals how simple principles of heat and pressure transformed the face of manufacturing, transportation, and global economies. From humble experiments in the early 18th century to grand locomotives and massive marine engines, steam power drove an industrial revolution that reshaped society. This article examines key milestones, technical breakthroughs, and enduring legacies of machines at work during the age of steam.

Origins of Steam Power

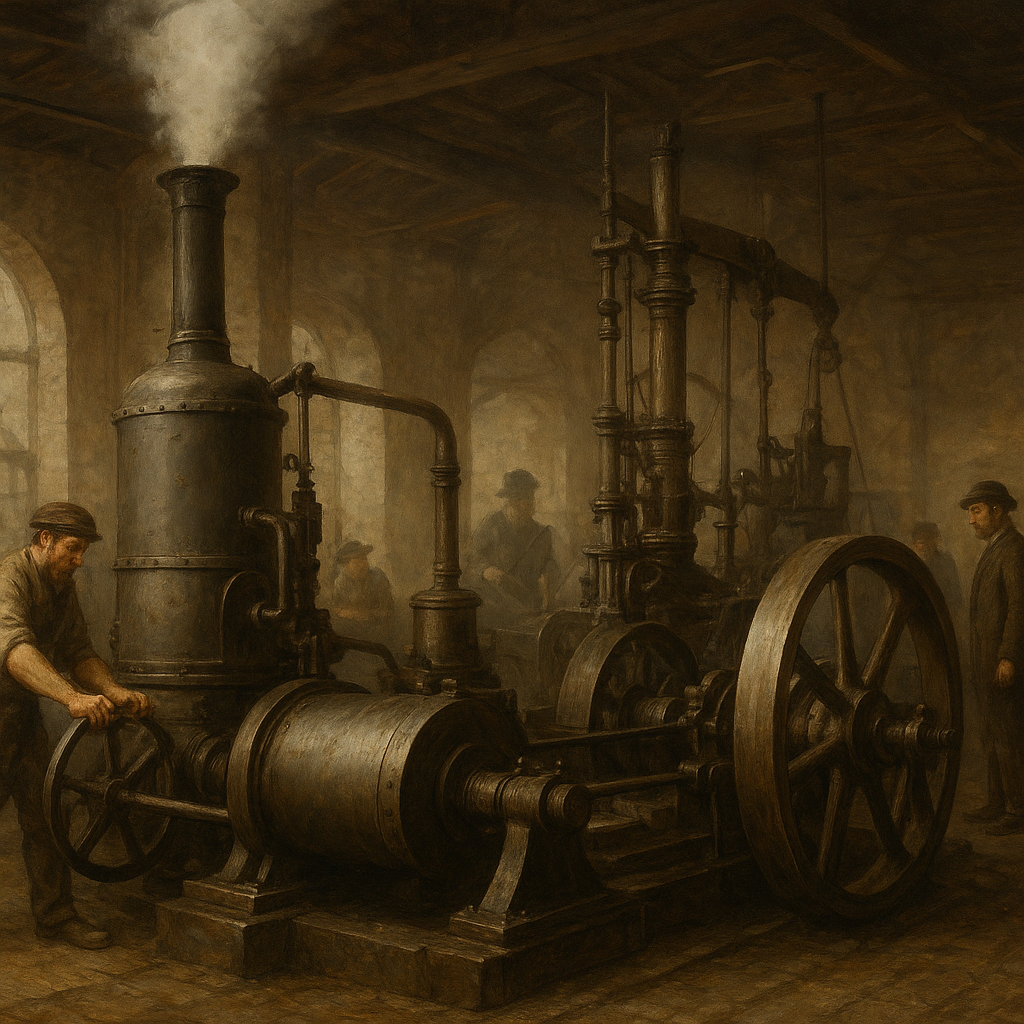

The exploration of steam’s potential began with inventors searching for a reliable source of power. Early prototypes relied on heated water generating high-pressure vapor to perform mechanical tasks. These pioneering devices laid the groundwork for more practical engines.

Early Experiments

- Hero of Alexandria’s aeolipile (1st century AD) demonstrated rotational motion from escaping steam.

- Denis Papin’s pressure cooker (late 17th century) featured a rudimentary boiler and safety valve.

- Thomas Savery’s “Miner’s Friend” (1698) pumped water from mines using steam pressure.

Key Principles

Understanding thermodynamics was critical. Inventors recognized that:

- Heating water converts it to steam, expanding rapidly and exerting force.

- Condensation creates a vacuum, allowing atmospheric pressure to drive pistons.

- Controlling steam flow and pressure through valves enabled repeatable efficiency.

Steam Engines and the Industrial Revolution

The 18th and 19th centuries saw rapid refinement of steam engines. James Watt introduced a separate condenser in 1765, drastically improving fuel consumption and making engines practical for factories and mines. Watt’s designs accelerated innovation across several industries.

Watt’s Breakthrough

By reducing heat loss, Watt’s engine achieved double the efficiency of previous models. His improvements included:

- A separate condenser to keep the cylinder hot.

- A rotary motion conversion mechanism for driving machinery.

- Adjustable governors to regulate speed automatically.

Impact on Manufacturing

Steam engines powered textile mills, ironworks, and workshop machinery. Factories could locate near resources and labor, no longer relying solely on water sources. Key effects included:

- Mass production of textiles using mechanized looms and spinning jennies.

- Expansion of iron and steel industries with steam-driven blast furnaces and rolling mills.

- Growth of urban centers as workers flocked to engine-powered factories.

Technological Innovations and Peak Performance

Continuous engineering advances pushed steam machinery to new heights. Pressure ratings, materials science, and component design all played roles in boosting power output and reliability.

High-Pressure Developments

Early low-pressure engines gave way to high-pressure units by the mid-19th century:

- Richard Trevithick built the first high-pressure piston engine in 1801, enabling more compact designs.

- High-pressure boilers delivered greater power density, suitable for locomotives and steamships.

- Improved metallurgy allowed boilers to withstand extreme temperatures and pressures.

Locomotives and Marine Engines

Steam locomotives revolutionized overland travel, while ocean-going vessels shrank global distances:

- The Rocket (1829) by George Stephenson set performance records with multi-tube boilers and advanced valve gear.

- Transatlantic steamships like the SS Great Western (1838) proved reliable ocean travel.

- Double-expansion and triple-expansion engines improved fuel economy by expanding steam in stages.

Legacy and Modern Adaptations of Steam Machinery

Despite the rise of internal combustion engines and electric motors, steam power left an enduring heritage in both technology and culture. Today, its principles still resonate in large-scale power generation and heritage railways.

Power Generation

Modern electric utilities rely on steam-driven turbines to convert heat into electricity:

- Fossil-fuel and nuclear plants produce high-pressure steam to spin > turbines connected to generators.

- Combined cycle systems recapture waste heat from gas turbines for additional steam stages, maximizing overall efficiency.

- Geothermal and solar-thermal installations also employ steam cycles for renewable power.

Preservation and Education

Historical machinery finds new life in museums, heritage railways, and static displays. Enthusiasts maintain working examples to demonstrate mechanical ingenuity and social transformation:

- Restored steam locomotives operate on tourist lines, showcasing period engineering.

- Live exhibits allow visitors to watch boilers, piston assemblies, and valve gear in motion.

- Workshops train new generations in the craftsmanship of riveting, machining, and boiler-making.

Lasting Influence

Steam-powered machinery taught vital lessons about energy conversion, material constraints, and scale-up challenges. These principles underpin modern mechanical engineering and power systems. The age of steam remains a testament to human creativity, transforming simple heat into the driving force of progress.