The following article provides a comprehensive look at the TBMs produced by NFM Technologies, their technical characteristics, typical applications, operational advantages and lifecycle considerations. It is intended for engineers, project managers, students and anyone interested in modern tunnelling technology. The content covers design principles, common configurations such as EPB and slurry machines, operational statistics as generally observed in the industry, and practical aspects of deployment, maintenance and environmental impact.

Overview and design principles

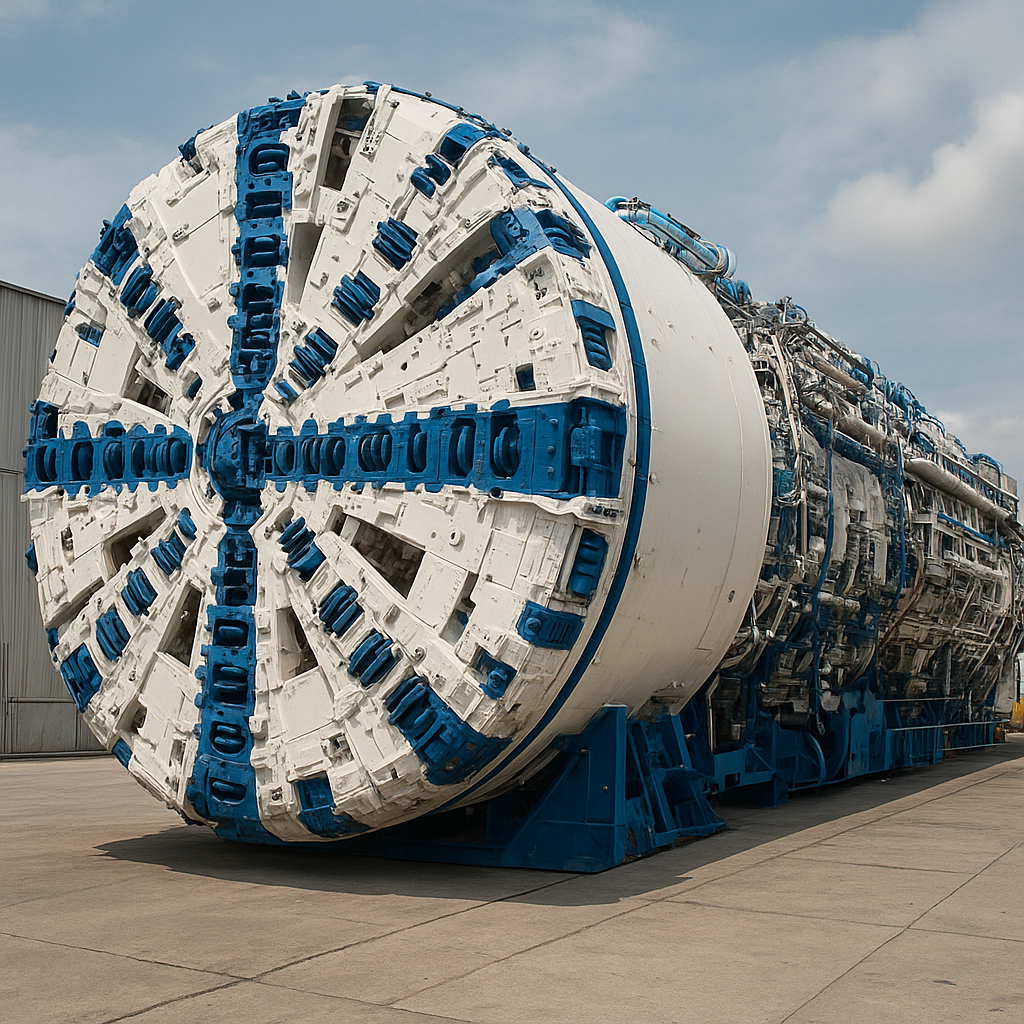

NFM Technologies is a manufacturer of mechanical tunnelling equipment that designs and supplies tunnel boring machines (TBMs) for a wide range of underground works. The core purpose of a TBM is to create a circular or arched tunnel with minimal surface disruption while simultaneously advancing excavation, supporting the tunnel, and handling the muck removal and segment installation processes when required. NFM machines are engineered to be modular, adaptable and suitable for differing ground conditions, from soft mixed soils to harder rock strata.

Key design elements

- Cutterhead: The rotating face that breaks and conditions the ground. Different cutterhead types are used for soil, mixed-face and hard-rock conditions.

- Thrust system: Hydraulic cylinders that push the machine forward and enable segment erection or lining operations.

- Torque transmission: Gearboxes and drives that deliver rotary power to the cutterhead to shear or grind material.

- Excavation chamber and muck handling: Systems designed for cuttings transport—belt conveyors, screw conveyors, slurry pipelines—depending on machine type.

- Shield and support systems: Structural elements that protect the crew and machinery; for segmental lining the erector places precast concrete rings.

- Control and automation: Integrated PLC/SCADA systems for real-time monitoring of face pressure, torque, advance, and machine diagnostics.

NFM machines typically follow industry best practices for modularity: the front shield (cutterhead), mid-body (equipment and conveyors), and rear section (thrust and backup) are manufactured in sections that can be transported by road and assembled on-site. This modular approach reduces logistical complexity while enabling customized arrangements for utilities such as slurry treatment plants or ventilation systems.

Types of NFM TBMs and their applications

TBMs are selected based on geological conditions, tunnel diameter and project-specific constraints like groundwater, urban proximity or environmental sensitivity. NFM Technologies supplies machines configured primarily as EPB (Earth Pressure Balance) and slurry TBMs, and can provide hybrid solutions or design adaptations for harder rock.

EPB TBMs

EPB machines are used where the ground consists of cohesive soils, sands and mixed-face conditions, especially when controlling face pressure and avoiding settlement on surface infrastructure is critical. The EPB system conditions the excavated material in the pressure chamber to create a paste-like medium that supports the face and is then removed via screw conveyors. EPB TBMs are common for urban metro tunnels, sewer tunnels and utility tunnels where settlement control is a priority.

Slurry TBMs

Slurry TBMs are used where high groundwater inflows, loose granular soils or unstable faces require the excavation chamber to be pressurized with a bentonite or polymer slurry. The slurry suspends the cuttings and transports them via pipelines to a surface treatment plant. Slurry machines are often chosen for river crossings, coastal tunnels or projects where controlling inflows and stabilizing the face chemically/physically is necessary.

Hard-rock and mixed-face configurations

For competent rock, an NFM TBM can be equipped with disc cutters and a robust cutterhead design. For highly variable geology, mixed-face cutterheads and adaptable support systems (such as dual-mode soil/rock arrangements) provide better resilience and continuous operation. NFM’s modular approach allows reinforcement of the cutterhead and changeover of tooling to suit evolving ground conditions.

Performance metrics and typical statistics

Performance of TBMs varies greatly with geology, tunnel diameter, tooling configuration and site logistics. The following figures are presented as typical industry ranges and benchmarks that help frame expectations for projects using NFM-style TBMs.

- Typical diameter range: 0.6 m (micro-tunnelling and pipe jacking) up to approximately 15 m for large civil and metro applications. NFM focuses mainly on small to medium and some large diameters depending on project needs.

- Advance rate (daily): Highly dependent on ground — commonly between 1 and 30 meters/day. In favorable, homogeneous conditions, short bursts can exceed 30 m/day, while mixed difficult ground may reduce progress to below 1–2 m/day.

- Thrust capacity: Varies by machine size and number of cylinders. Typical ranges for modern TBMs are from a few hundred kilonewtons for small machines to several thousand kilonewtons for large shields. Thrust must exceed ring-erection and face-resistance requirements for the given ground.

- Cutterhead torque: Designed to match geology and cutter design; torque ranges can span from a few hundred kilonewton-meters to several thousand kilonewton-meters for big-diameter machines.

- Muck handling rates: Depend on TBM diameter and type; EPB machines rely on screw conveyors rated to move conditioned spoil at rates matching excavation speed; slurry TBMs send slurries at pipeline flow rates engineered per the spoil volume generated.

- Power consumption: TBM drive power is a major operational parameter, often in the range of several hundred kilowatts for small TBMs up to multiple megawatts for very large machines. Power is dominated by cutterhead drives and conveyors.

Note: The exact numbers for any NFM-supplied TBM depend on the final design and contract. Project-specific geotechnical investigations and machine design produce the precise thrust, torque, power and advance-rate specifications.

Operational advantages and innovations

NFM Technologies emphasizes adaptability, efficiency and safety in their machine designs. Important operational benefits include:

- Modular transportable units that simplify logistics and reduce on-site assembly time.

- Customizable cutterheads and tooling packages that optimize performance across mixed geology.

- Advanced monitoring and control systems that improve decision-making and reduce downtime through predictive alarms and diagnostics—elements of automation that increase productivity.

- Integrated muck handling and dust/sediment control systems that maintain a safer, cleaner work environment.

- Compatibility with segmental lining systems, enabling immediate structural support behind the TBM in urban tunnelling projects.

Automation and digital integration

Modern TBMs incorporate digital systems for process control, remote diagnostics and data logging. NFM-equipped machines typically include:

- Real-time telemetry for parameters such as face pressure, cutterhead torque, thrust and conveyor load.

- Automated alarms and interlocks to prevent over-thrust or over-torque conditions.

- Data platforms that allow project teams to analyze machine performance, predict maintenance windows and optimize advance sequences.

Project types and real-world applications

NFM TBMs are adopted for a wide spectrum of tunnelling works. Typical applications include:

- Urban metro and light-rail tunnels where surface disruption must be minimized and settlement controlled.

- Road tunnels and bypasses to relieve congestion or create new underground corridors.

- Sewer and stormwater tunnels—often medium diameter EPB machines offer an efficient solution.

- Water conveyance and pressure tunnels—slurry TBMs or hard-rock machines as required by hydrogeology.

- Industrial utility ducts for power, telecom and multi-utility corridors where continuous service routes are needed.

- Underwater or river crossings where slurry systems and specialized sealing techniques are mandatory.

Examples of typical project phases where a TBM is central:

- Pre-construction: selection of TBM type, diameter and main drives based on geotechnical data.

- Assembly and launch: formation of launch pit, assembly of TBM modules and commissioning.

- Drive and lining: continuous excavation with segment installation or rock support as required.

- Breakout and retrieval: completion at receiving shaft, disassembly and removal or reconfiguration for subsequent drives.

Logistics, maintenance and lifecycle considerations

A TBM’s success depends as much on planning, logistics and maintenance as on the mechanical design. Key lifecycle considerations include:

- Pre-assembly site layout: sufficient space for sections, backup systems, turbines/generators, and slurry handling plants.

- Cutter and tooling replacement: robust supply chains for disc cutters, scrapers, sealing elements and wear parts reduce delays.

- Preventive maintenance schedules: regular inspection of seals, bearings, hydraulic systems and electrical equipment maintains uptime.

- Spare parts strategy: stocking critical spares on-site or having fast delivery agreements with suppliers.

- Training and workforce: skilled TBM operators, mechanics and control technicians significantly affect productivity.

Operational downtime is often driven by ground-related events (settlement, clogging, groundwater inflow) and by tooling wear. NFM tends to supply training and remote support to expedite troubleshooting and optimize maintenance cycles.

Safety, environment and sustainability

TBMs offer environmental and safety advantages compared with traditional drill-and-blast or open-cut tunnelling:

- Reduced surface disruption: minimal need for open trenches or road closures, benefiting urban environments and limiting ecological impact.

- Lower vibration and noise levels compared with blasting—important for operations near sensitive structures and populations.

- Containment of spoil and controlled handling: EPB and slurry systems reduce airborne dust and allow conditioned or treated disposal of excavated materials.

- Energy efficiency improvements via optimized cutterhead design and power management reduce the carbon intensity of tunnelling operations over time.

Environmental management plans for TBM projects typically include sediment control, slurry treatment and recycling, noise barriers around launch/receiving sites and monitoring of settlement and ground-water conditions to prevent unintended impacts.

Economic and project-delivery considerations

Using TBMs from manufacturers like NFM Technologies shapes the economics of tunnelling projects in several ways:

- Upfront capital cost for a TBM can be high, but for long drives the unit cost per meter often becomes competitive due to higher daily advance and reduced reinstatement costs at surface.

- Short drives or projects with numerous curves and tight alignments may favor alternative methods; TBMs are most economical on longer, straighter alignments.

- Predictability: controlled mechanized excavation reduces risk associated with variable labor productivity and weather, improving schedule reliability.

- Maintenance and spare parts contribute to lifecycle cost—good OEM support and remote diagnostics can reduce the total cost of ownership.

Interesting technical innovations and trends

Recent trends in TBM technology—reflected in the designs adopted by modern suppliers including NFM—include:

- Higher levels of automation: from aided cut-rate optimization to automated cutter replacement assists.

- Integration with BIM and digital twin frameworks to model TBM performance versus design and geotechnical predictions.

- Improved sealing materials and face-grouting technologies to better handle high-pressure groundwater conditions.

- Modular powerpacks and electrically driven drives that enable more compact layouts and lower emissions at sites.

- Better wear-monitoring sensors that extend cutter life and optimize replacement timing.

Choosing the right TBM and procurement tips

Selecting an appropriate TBM involves technical, contractual and logistical choices:

- Match TBM type to dominant geology—EPB for cohesive and mixed soils, slurry for watery granular soils, hard-rock cutters for competent rock.

- Assess diameter carefully: larger diameters increase cost exponentially; optimize tunnel cross-section to project needs.

- Consider procurement models: hire (rental) versus buy; for short-term or single small drives, rental may be more economical.

- Factor in spares, tooling and training in contract negotiations with the manufacturer.

- Define clear performance guarantees and acceptance criteria for advance rates, settlement, and machine availability.

Summary and final observations

NFM Technologies produces TBMs that reflect modern tunnelling practice: modular machines adaptable to a wide range of ground conditions, incorporating advanced monitoring and support systems to improve productivity and safety. While exact performance depends on the specific machine configuration and project geology, TBMs remain the preferred solution for many urban tunnelling projects, long drives and works where surface impact must be minimized. By combining robust mechanical design with digital control, modern NFM-style TBMs increase predictability, reduce environmental footprint and deliver efficient underground construction when properly matched to site conditions.

TBM deployment should always be accompanied by thorough geotechnical investigations, careful planning of logistics and maintenance, and a clear procurement strategy that balances capital cost, project duration and operational risk. With continuing innovations in automation, monitoring and materials, TBMs from leading suppliers will remain central to the expansion of underground infrastructure in the coming decades.