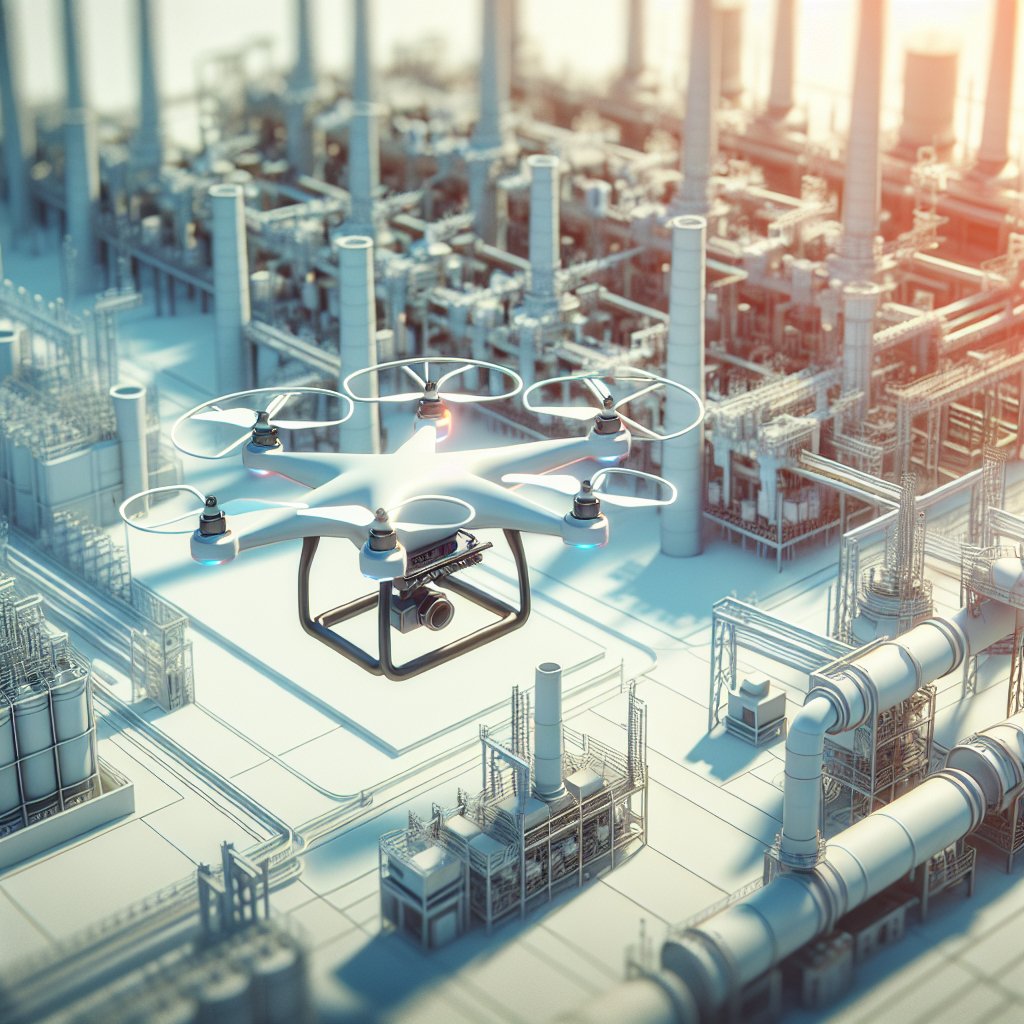

In recent years, the integration of drones into industrial inspections has revolutionized the way companies approach maintenance and safety checks. These unmanned aerial vehicles (UAVs) have proven to be invaluable tools, offering a range of benefits that enhance efficiency, reduce costs, and improve safety standards across various industries. This article delves into the transformative impact of drones on industrial inspections, exploring their applications, advantages, and the future potential of this technology.

Applications of Drones in Industrial Inspections

Drones have found a wide array of applications in industrial inspections, thanks to their versatility and ability to access hard-to-reach areas. One of the primary uses of drones is in the inspection of infrastructure such as bridges, pipelines, and power lines. Traditionally, these inspections required significant manpower and equipment, often involving scaffolding, cranes, or helicopters. Drones, however, can quickly and safely survey these structures, capturing high-resolution images and videos that provide detailed insights into their condition.

In the oil and gas industry, drones are employed to inspect offshore rigs and refineries. These environments are often hazardous and challenging for human inspectors, but drones can navigate them with ease, reducing the risk to personnel. Equipped with thermal imaging cameras, drones can detect leaks, corrosion, and other anomalies that may not be visible to the naked eye, allowing for timely maintenance and repairs.

The renewable energy sector also benefits from drone technology, particularly in the inspection of wind turbines and solar panels. Drones can fly close to turbine blades and solar arrays, identifying damage or inefficiencies that could impact energy production. This capability not only ensures optimal performance but also extends the lifespan of these assets.

Advantages of Using Drones for Inspections

The adoption of drones in industrial inspections offers numerous advantages that contribute to improved efficiency and cost-effectiveness. One of the most significant benefits is the reduction in inspection time. Drones can cover large areas quickly, gathering data in a fraction of the time it would take a human team. This speed translates to less downtime for industrial operations, minimizing disruptions and maximizing productivity.

Cost savings are another major advantage. Traditional inspection methods often involve significant expenses related to equipment rental, labor, and safety measures. Drones, on the other hand, require minimal setup and can be operated by a small team, leading to substantial cost reductions. Additionally, the ability to conduct more frequent inspections at a lower cost allows companies to adopt a proactive maintenance approach, addressing issues before they escalate into costly repairs.

Safety is a paramount concern in industrial inspections, and drones significantly enhance safety standards. By eliminating the need for inspectors to work at heights or in hazardous environments, drones reduce the risk of accidents and injuries. This not only protects personnel but also ensures compliance with safety regulations, avoiding potential fines and legal issues.

Challenges and Future Potential

Despite their many advantages, the use of drones in industrial inspections is not without challenges. Regulatory hurdles, such as restrictions on drone flights in certain areas and the need for operator certification, can pose obstacles to widespread adoption. Additionally, the integration of drone data into existing systems and processes requires investment in technology and training.

However, the future potential of drones in industrial inspections is immense. Advances in drone technology, such as improved battery life, enhanced sensors, and autonomous flight capabilities, are set to further expand their applications. The integration of artificial intelligence and machine learning will enable drones to analyze data in real-time, providing actionable insights and predictive maintenance recommendations.

As industries continue to recognize the value of drones, we can expect to see increased investment in this technology, leading to even greater efficiency and innovation in industrial inspections. The ongoing development of drone regulations and standards will also play a crucial role in facilitating their adoption, ensuring that drones can be used safely and effectively across various sectors.

In conclusion, drones are transforming the landscape of industrial inspections, offering a host of benefits that enhance efficiency, reduce costs, and improve safety. As technology continues to evolve, the role of drones in industrial inspections is set to grow, paving the way for a more efficient and sustainable future.