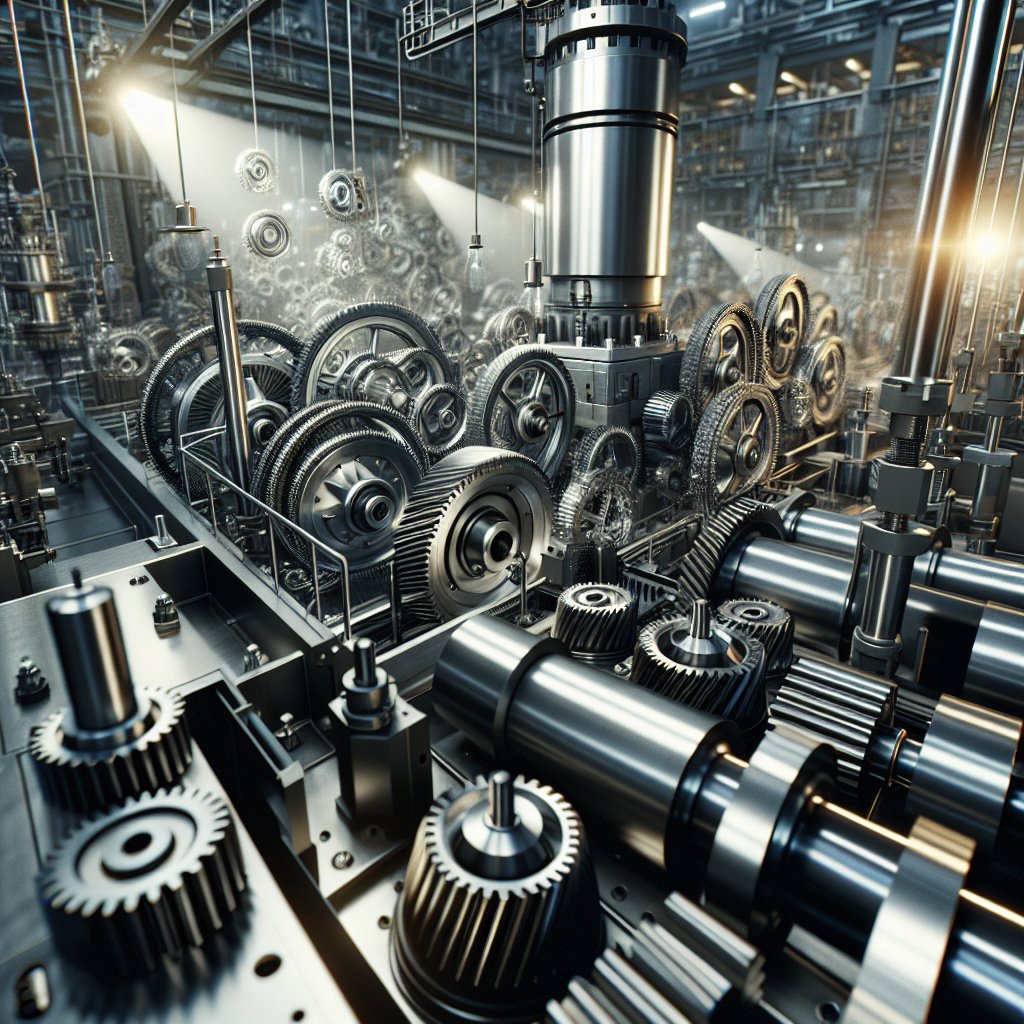

Industrial gear manufacturing is a critical component of modern machinery, playing a pivotal role in various industries such as automotive, aerospace, and energy. The process of creating these intricate components involves a blend of traditional techniques and cutting-edge innovations. This article delves into the challenges faced by the industry and the innovative solutions that are shaping its future.

Challenges in Industrial Gear Manufacturing

The manufacturing of industrial gears is fraught with numerous challenges that can impact both the efficiency and quality of the final product. One of the primary challenges is the precision required in gear production. Gears must meet exact specifications to function correctly, and even minor deviations can lead to significant performance issues. This necessitates the use of advanced machinery and skilled labor, both of which can be costly.

Another significant challenge is the material selection. Gears are often subjected to high levels of stress and must be made from materials that can withstand these conditions without degrading. This requires a deep understanding of material properties and the ability to source high-quality raw materials. Additionally, the manufacturing process itself can introduce stresses and defects into the gears, which must be carefully managed to ensure durability and performance.

Environmental concerns also pose a challenge to gear manufacturers. The production process can be energy-intensive and generate waste, leading to a push for more sustainable practices. Manufacturers must balance the need for high-quality products with the demand for environmentally friendly processes, which can require significant investment in new technologies and practices.

Innovations in Gear Manufacturing

Despite these challenges, the industrial gear manufacturing industry is experiencing a wave of innovation that is helping to overcome these obstacles. One of the most significant advancements is the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. These tools allow for greater precision in the design and production of gears, reducing the likelihood of errors and improving overall quality.

3D printing is another innovation that is beginning to make its mark on the industry. While still in its early stages, 3D printing offers the potential to create complex gear geometries that would be difficult or impossible to achieve with traditional manufacturing methods. This technology also allows for rapid prototyping, enabling manufacturers to test and refine designs more quickly and cost-effectively.

In terms of materials, there is ongoing research into new alloys and composites that offer improved performance characteristics. These materials can provide greater strength and durability while also being lighter and more resistant to wear and corrosion. This can lead to longer-lasting gears that require less maintenance and are more efficient in operation.

Automation is also playing a crucial role in the evolution of gear manufacturing. Automated systems can handle repetitive tasks with high precision, reducing the potential for human error and increasing production efficiency. This not only helps to lower costs but also allows manufacturers to produce gears at a larger scale to meet growing demand.

Conclusion

The industrial gear manufacturing industry is at a crossroads, facing significant challenges but also embracing exciting innovations. As technology continues to advance, manufacturers are finding new ways to improve the precision, efficiency, and sustainability of their processes. By leveraging these innovations, the industry is poised to meet the demands of the future, providing high-quality gears that power the machinery of tomorrow.