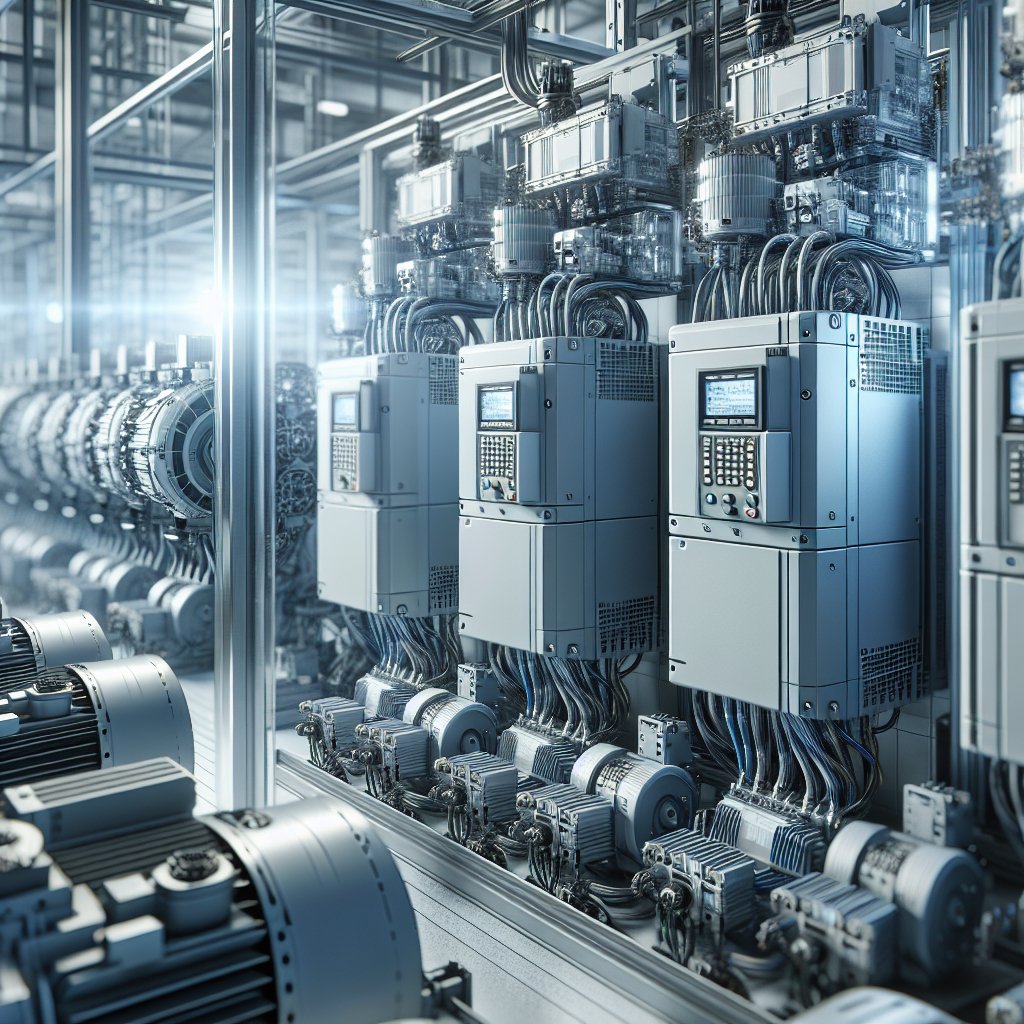

Variable Frequency Drives (VFDs) have become an essential component in the realm of industrial motor control, offering a myriad of benefits that enhance efficiency, performance, and reliability. As industries continue to evolve, the demand for more sophisticated and energy-efficient motor control systems has led to the widespread adoption of VFDs. This article delves into the critical role that VFDs play in industrial motor control, exploring their functionality, advantages, and applications across various sectors.

Understanding Variable Frequency Drives

Variable Frequency Drives, also known as adjustable-speed drives or inverters, are electronic devices that control the speed and torque of electric motors by varying the frequency and voltage of the power supplied to the motor. The primary function of a VFD is to adjust the motor’s speed to match the specific requirements of the application, thereby optimizing energy consumption and improving process control.

At the heart of a VFD is a sophisticated control system that converts the fixed-frequency AC power from the grid into a variable-frequency AC output. This conversion process involves three main stages: rectification, DC bus, and inversion. During rectification, the AC input is converted into DC power. The DC bus stage smooths and stabilizes the DC power, and finally, the inversion stage converts the DC back into AC power with a variable frequency and voltage.

The ability to precisely control motor speed and torque makes VFDs invaluable in a wide range of industrial applications. From simple fan and pump systems to complex manufacturing processes, VFDs offer unparalleled flexibility and control, enabling industries to achieve higher levels of efficiency and productivity.

Advantages of Using Variable Frequency Drives

The adoption of VFDs in industrial settings brings numerous advantages, making them a preferred choice for motor control. Some of the key benefits include:

- Energy Efficiency: One of the most significant advantages of VFDs is their ability to reduce energy consumption. By adjusting the motor speed to match the load requirements, VFDs minimize energy waste, leading to substantial cost savings and a reduced carbon footprint.

- Improved Process Control: VFDs offer precise control over motor speed and torque, allowing for smoother operation and better process control. This precision is particularly beneficial in applications where maintaining consistent speed and torque is critical, such as in conveyor systems and production lines.

- Extended Equipment Life: By reducing mechanical stress on motors and associated equipment, VFDs help extend the lifespan of machinery. Soft starting and stopping capabilities minimize wear and tear, reducing maintenance costs and downtime.

- Reduced Mechanical Stress: VFDs provide soft start and stop functions, which reduce the mechanical stress on motors and connected equipment. This feature is particularly beneficial in applications where sudden starts and stops can cause damage or wear.

- Enhanced System Reliability: With advanced monitoring and diagnostic capabilities, VFDs can detect and respond to potential issues before they lead to system failures. This proactive approach enhances overall system reliability and reduces the risk of unexpected downtime.

Applications of Variable Frequency Drives in Industry

Variable Frequency Drives are utilized across a wide range of industries, each benefiting from the unique capabilities of these devices. Some common applications include:

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, VFDs are used to control the speed of fans, pumps, and compressors. By adjusting motor speed based on demand, VFDs improve energy efficiency and maintain optimal environmental conditions.

- Pumping Systems: VFDs are widely used in water and wastewater treatment facilities to control the speed of pumps. This control ensures efficient operation, reduces energy consumption, and minimizes water hammer effects.

- Manufacturing and Production: In manufacturing environments, VFDs are employed to control conveyor belts, mixers, and other machinery. The precise speed control offered by VFDs enhances production efficiency and product quality.

- Mining and Extraction: In the mining industry, VFDs are used to control the speed of crushers, mills, and conveyors. This control optimizes the extraction process, reduces energy consumption, and minimizes equipment wear.

- Renewable Energy: VFDs play a crucial role in renewable energy systems, such as wind turbines and solar power plants. By controlling the speed of generators and inverters, VFDs maximize energy output and ensure stable grid integration.

Challenges and Considerations in Implementing VFDs

While the benefits of VFDs are substantial, their implementation in industrial settings is not without challenges. Some of the key considerations include:

- Harmonics and Power Quality: VFDs can introduce harmonics into the electrical system, potentially affecting power quality and causing issues with other equipment. Proper filtering and mitigation strategies are essential to address these concerns.

- Initial Cost and Complexity: The initial cost of VFDs and the complexity of their installation can be a barrier for some industries. However, the long-term energy savings and operational benefits often outweigh the initial investment.

- Environmental Conditions: VFDs must be designed to withstand the environmental conditions of the application, such as temperature, humidity, and dust. Proper enclosure and cooling solutions are necessary to ensure reliable operation.

- Compatibility with Existing Systems: Integrating VFDs into existing systems may require modifications to control systems and infrastructure. Ensuring compatibility and seamless integration is crucial for successful implementation.

The Future of Variable Frequency Drives in Industry

As industries continue to prioritize energy efficiency and sustainability, the role of Variable Frequency Drives is expected to grow. Advances in technology are leading to the development of more compact, efficient, and intelligent VFDs, further enhancing their capabilities and applications.

Emerging trends such as the Industrial Internet of Things (IIoT) and smart manufacturing are driving the integration of VFDs with advanced monitoring and control systems. This integration enables real-time data analysis, predictive maintenance, and remote monitoring, further improving operational efficiency and reducing downtime.

In conclusion, Variable Frequency Drives are a vital component of modern industrial motor control, offering significant benefits in terms of energy efficiency, process control, and equipment longevity. As technology continues to evolve, VFDs will play an increasingly important role in shaping the future of industrial automation and sustainability.