Hydraulic systems form the unseen backbone of countless industrial and mobile machines, transforming **fluid** energy into precise **mechanical** motion. By exploiting the principles of **pressure** and force multiplication, these systems deliver the high **power** density required for heavy-duty tasks. Throughout this article, we explore the core principles, operational benefits, and evolving innovations that make hydraulic technology indispensable in modern machinery.

Fundamentals of Hydraulic Systems

Principle of Operation

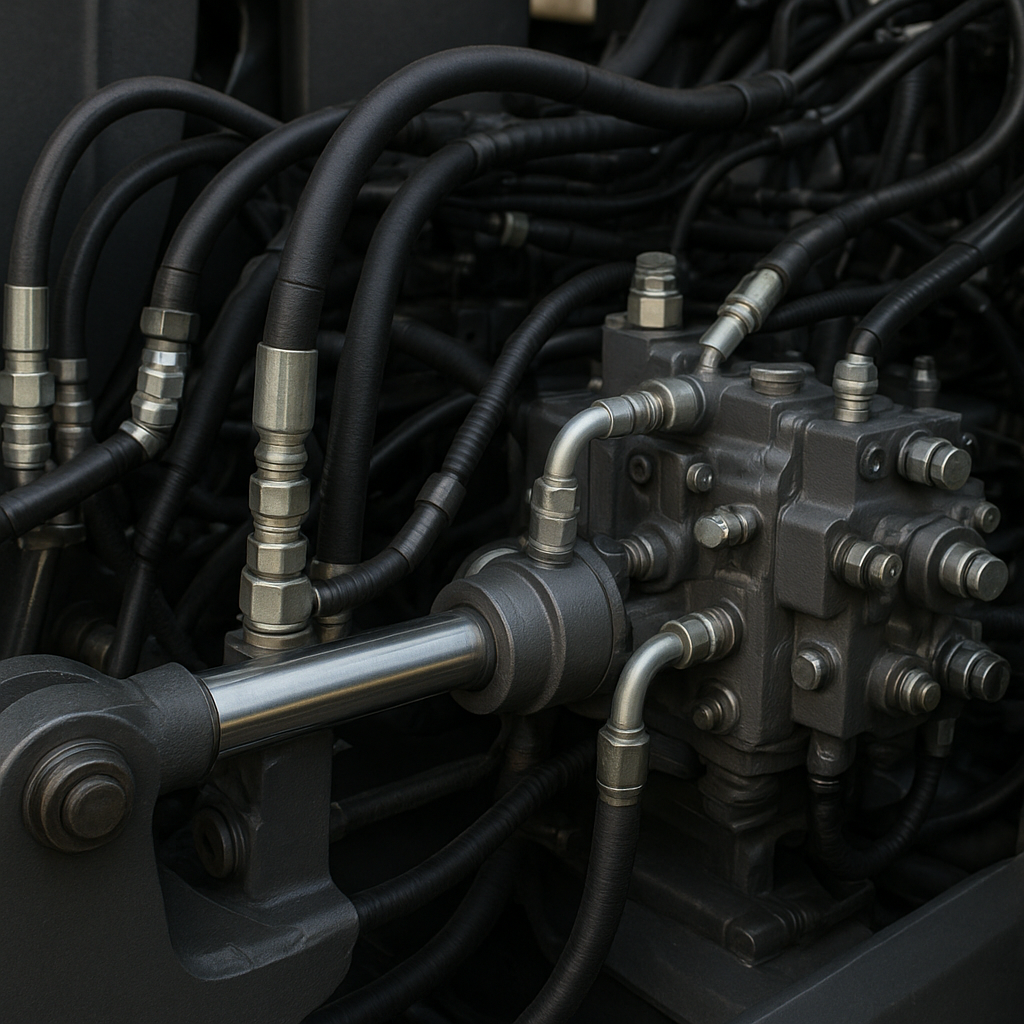

The heart of any hydraulic setup is Pascal’s law, which states that pressure applied to a confined **liquid** is transmitted equally in all directions. This simple yet powerful concept enables operators to generate tremendous force with minimal input. A typical circuit begins at a pump, converting mechanical drive energy into hydraulic energy. As the pump pushes the fluid through pipelines, pressure builds up and is regulated by valves. This regulated pressure is then used to drive actuators like cylinders or motors, producing linear or rotary motion.

Key Components

Understanding each component’s role is crucial for both design and troubleshooting:

- Pump: Supplies the **fluid** flow and creates system **pressure**.

- Reservoir: Stores hydraulic oil and dissipates heat.

- Valves: Control direction, flow rate, and system pressure.

- Cylinders and Motors: Convert fluid power into linear or rotary motion.

- Filters: Remove contaminants to protect **components** and maintain **efficiency**.

- Accumulators: Store energy and smooth pressure fluctuations.

Each of these elements must be carefully selected and precisely integrated to ensure optimal performance, reliability, and safety.

Advantages and Challenges in Industry

Efficiency and Control

Hydraulic systems excel in applications demanding high force and precise positioning. Key advantages include:

- High Power Density: Compact **cylinders** can deliver enormous thrust in a small envelope.

- Smooth Motion: Fine adjustment of **flow** rates allows for gradual start-up and stopping.

- Remote Operation: Long hoses enable control from safe distances in hazardous environments.

- Load-Holding Capability: Check valves and accumulators maintain position without continuous energy input.

Nevertheless, designers must address challenges such as energy losses due to fluid friction, potential leaks, and heat generation, all of which can impact overall system **efficiency**.

Maintenance and Safety

Regular **maintenance** is vital to sustain reliability and prevent costly downtime. Key practices include:

- Monitoring fluid cleanliness via particle counters and visual inspections.

- Checking pressure levels and adjusting relief valves to avoid over-pressurization.

- Inspecting seals, hoses, and fittings for signs of wear or leakage.

- Maintaining optimal fluid temperature through proper cooling systems.

Adhering to stringent safety protocols is equally critical. Overlooked leaks can cause slips, fire hazards, and environmental contamination. Pressure accidents may result in serious injuries. Training personnel in lockout-tagout procedures and the correct use of personal protective equipment ensures a safer working environment.

Applications in Various Sectors

Construction Machinery

Excavators, loaders, and bulldozers rely heavily on hydraulic circuits to handle heavy earthmoving tasks. The ability to generate adjustable force makes hydraulic arms versatile for digging, lifting, and precise grading operations. **Power** delivery is continuous and can be smoothly modulated to match varying ground conditions.

Manufacturing and Automation

In industrial production lines, hydraulic presses, injection molding machines, and stamping equipment use high **pressure** to shape metals and plastics. These machines demand consistent force for repeatable results, making hydraulics the technology of choice for high-volume operations. The integration of proportional valves and CNC controls further enhances motion accuracy.

Transportation and Aerospace

Hydraulic actuators govern brakes, steering systems, and landing gear in heavy vehicles and aircraft. The technology’s reliability and capability to handle extreme loads are crucial for safety-critical functions. In aviation, redundancy in hydraulic circuits ensures consistent performance even in case of partial failure.

Innovations and Future Trends

Smart Hydraulics

The advent of sensors, electronics, and data analytics has given rise to “smart” hydraulic systems. Real-time monitoring of **pressure**, temperature, and flow rates allows for predictive **maintenance**, reducing downtime and extending component life. Integrated controllers can adjust operating parameters on the fly to maximize **efficiency** and adapt to changing load demands.

Environmental Considerations

With growing emphasis on sustainability, the industry is exploring biodegradable and low-toxicity fluids. These eco-friendly oils minimize environmental impact in case of leaks. Innovations in heat recovery systems harness waste heat generated by hydraulic circuits, converting it back into usable energy and lowering overall power consumption.

Energy-Efficient Designs

New valve technologies and variable displacement pumps reduce parasitic losses by matching fluid delivery precisely to workload requirements. Closed-loop circuits reclaim and recirculate fluid, further enhancing **efficiency**. Hybrid electro-hydraulic systems combine electric drives with hydraulic actuators to achieve optimal energy usage across diverse operational regimes.

Miniaturization and Mobility

Advances in materials and micro-manufacturing enable the production of smaller, lighter hydraulic elements capable of high **power** output. Portable hydraulic tools and wearable exoskeletons benefit from compact pumps and low-noise components, opening new possibilities in maintenance, rescue operations, and medical rehabilitation.