Gearboxes play a crucial role in the operation of industrial machines, serving as the backbone of mechanical power transmission systems. These essential components are responsible for adjusting the output speed and torque of motors to meet the specific requirements of various industrial applications. In this article, we will explore the fundamental aspects of gearboxes, their types, and their significance in industrial machinery.

Understanding Gearboxes

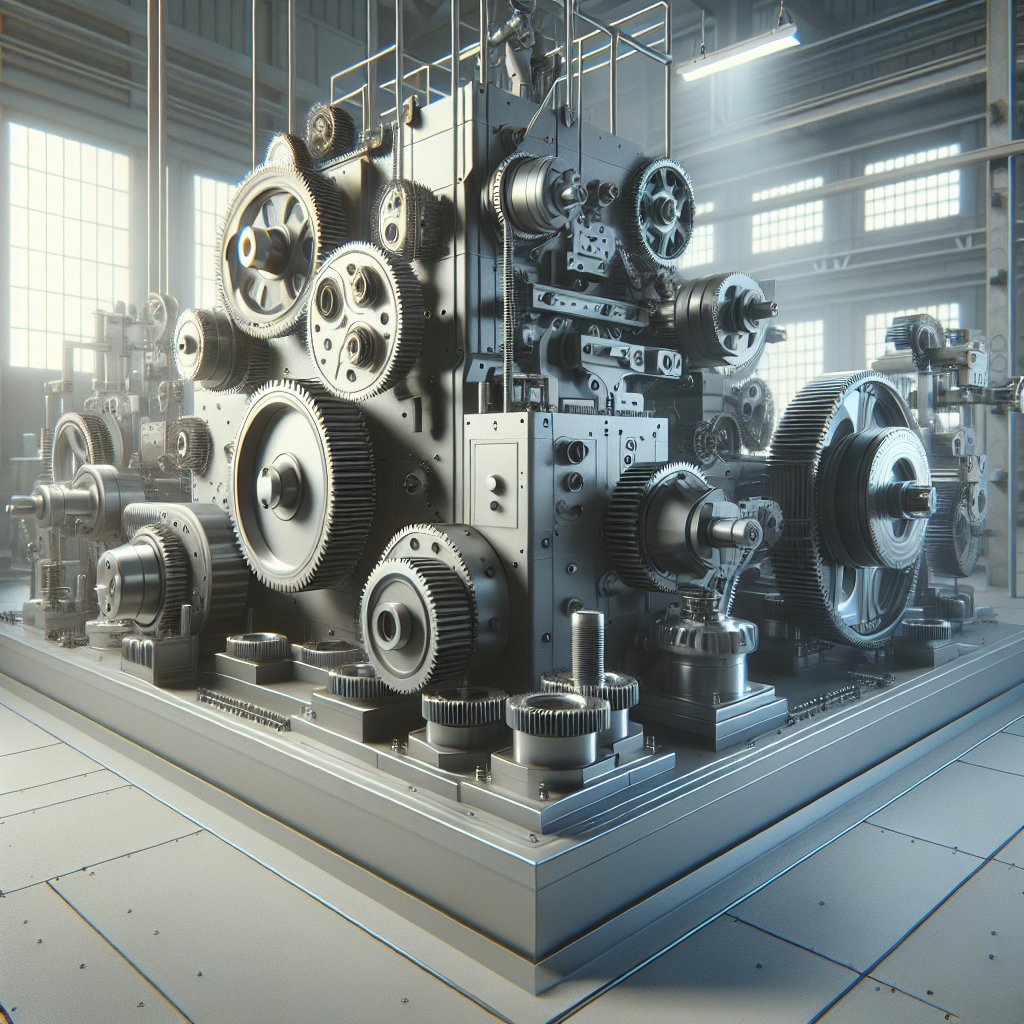

At the heart of many industrial machines, gearboxes are mechanical devices that transmit power from a motor to a driven load. They achieve this by altering the speed and torque of the motor’s output shaft, making it suitable for the intended application. The primary function of a gearbox is to convert the high-speed, low-torque output of a motor into a lower-speed, higher-torque output, which is often required for heavy-duty industrial tasks.

Gearboxes consist of a series of gears, shafts, and bearings enclosed within a housing. The gears inside the gearbox mesh together to transmit power from the input shaft to the output shaft. By changing the gear ratio, gearboxes can increase or decrease the speed and torque of the output shaft, allowing for precise control over the machine’s performance.

Types of Gearboxes

There are several types of gearboxes used in industrial applications, each designed to meet specific requirements. Some of the most common types include:

- Helical Gearboxes: Known for their efficiency and smooth operation, helical gearboxes use angled teeth to transmit power between parallel or non-parallel shafts. They are widely used in applications requiring high torque and low noise levels.

- Bevel Gearboxes: These gearboxes are used to transmit power between intersecting shafts. They are commonly found in applications where a change in the direction of the drive is necessary, such as in conveyor systems.

- Worm Gearboxes: Featuring a worm gear and a worm wheel, these gearboxes are ideal for applications requiring high torque and low speed. They offer excellent shock absorption and are often used in heavy machinery.

- Planetary Gearboxes: Known for their compact design and high efficiency, planetary gearboxes consist of a central sun gear, planet gears, and a ring gear. They are used in applications requiring high precision and torque density.

The Importance of Gearboxes in Industrial Machines

Gearboxes are indispensable in industrial machines for several reasons. Firstly, they allow for the efficient transmission of power from the motor to the driven load, ensuring that the machine operates at the desired speed and torque. This is particularly important in applications where precise control over the machine’s performance is required, such as in manufacturing and processing industries.

Secondly, gearboxes help to protect the motor from excessive loads and shocks. By adjusting the speed and torque of the output shaft, gearboxes can prevent the motor from being overloaded, which can lead to premature wear and failure. This not only extends the lifespan of the motor but also reduces maintenance costs and downtime.

Moreover, gearboxes contribute to the overall efficiency of industrial machines. By optimizing the power transmission process, gearboxes can reduce energy consumption and improve the machine’s performance. This is particularly important in industries where energy efficiency is a key concern, such as in the automotive and aerospace sectors.

Applications of Gearboxes in Industry

Gearboxes are used in a wide range of industrial applications, from simple conveyor systems to complex manufacturing processes. Some of the most common applications include:

- Conveyor Systems: Gearboxes are used to control the speed and torque of conveyor belts, ensuring the smooth and efficient movement of materials.

- Pumps and Compressors: In these applications, gearboxes are used to adjust the speed and torque of the motor to match the requirements of the pump or compressor.

- Mixers and Agitators: Gearboxes are used to control the speed and torque of mixers and agitators, ensuring the proper mixing of materials.

- Machine Tools: In machine tools, gearboxes are used to control the speed and torque of cutting tools, ensuring precise and efficient machining operations.

Conclusion

In conclusion, gearboxes are vital components in industrial machines, playing a key role in the efficient transmission of power from the motor to the driven load. By adjusting the speed and torque of the output shaft, gearboxes ensure that industrial machines operate at the desired performance levels, while also protecting the motor from excessive loads and shocks. With their wide range of applications and benefits, gearboxes are indispensable in the modern industrial landscape.