Electric actuators have become a cornerstone in the realm of industrial automation, offering precision, efficiency, and reliability. As industries continue to evolve, the demand for advanced automation solutions has surged, placing electric actuators at the forefront of technological innovation. This article delves into the pivotal role that electric actuators play in industrial automation, exploring their benefits, applications, and future potential.

Understanding Electric Actuators

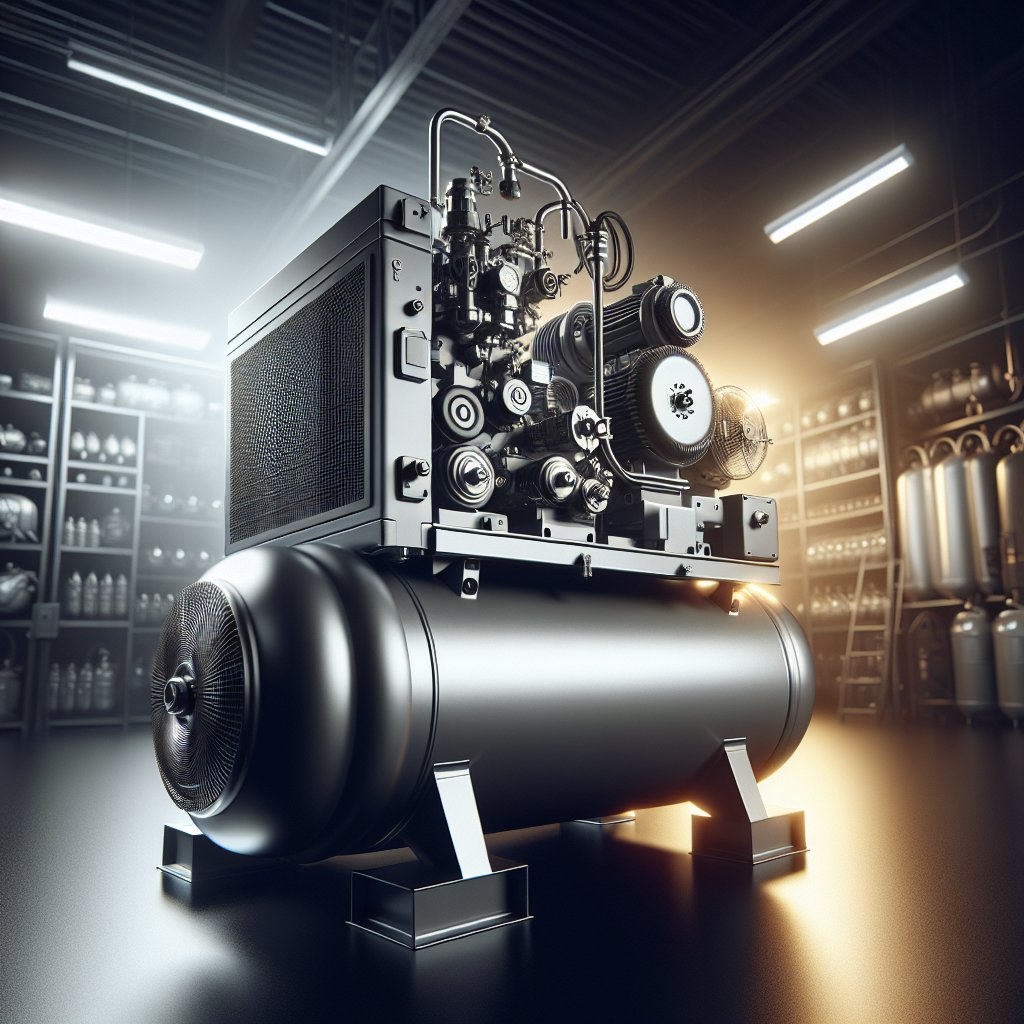

Electric actuators are devices that convert electrical energy into mechanical motion. They are integral components in various automation systems, providing the necessary movement and control for machinery and equipment. Unlike their pneumatic or hydraulic counterparts, electric actuators offer a cleaner, more energy-efficient solution, making them increasingly popular in modern industrial settings.

Types of Electric Actuators

There are several types of electric actuators, each designed to meet specific industrial needs. The most common types include:

- Linear Actuators: These actuators provide motion in a straight line, making them ideal for applications requiring precise linear movement.

- Rotary Actuators: As the name suggests, rotary actuators produce rotational motion, commonly used in applications such as valve control and robotic arms.

- Servo Actuators: Known for their high precision and control, servo actuators are used in applications where exact positioning is crucial.

Each type of actuator has its unique advantages and is selected based on the specific requirements of the application.

Benefits of Electric Actuators in Industrial Automation

The adoption of electric actuators in industrial automation offers numerous benefits, contributing to enhanced operational efficiency and productivity.

Energy Efficiency

Electric actuators are renowned for their energy efficiency. Unlike pneumatic or hydraulic systems, which often suffer from energy losses due to leaks and inefficiencies, electric actuators convert electrical energy directly into mechanical motion with minimal waste. This efficiency translates into lower operational costs and a reduced environmental footprint.

Precision and Control

One of the standout features of electric actuators is their ability to provide precise control over motion. This precision is crucial in applications where accuracy is paramount, such as in the manufacturing of delicate components or in automated assembly lines. The ability to program and control electric actuators with high accuracy ensures consistent and reliable performance.

Low Maintenance

Electric actuators require less maintenance compared to their pneumatic and hydraulic counterparts. They have fewer moving parts and do not rely on fluids, which can lead to leaks and contamination. This reduced maintenance requirement not only lowers operational costs but also minimizes downtime, ensuring continuous production.

Applications of Electric Actuators in Industrial Automation

Electric actuators are versatile components used across a wide range of industries and applications. Their adaptability and reliability make them suitable for various automation tasks.

Manufacturing and Assembly

In manufacturing and assembly lines, electric actuators are used to automate repetitive tasks, such as moving parts along a conveyor belt, assembling components, or packaging products. Their precision and speed enhance productivity and ensure consistent quality.

Robotics

Robotic systems heavily rely on electric actuators for movement and control. Whether it’s a robotic arm in a car manufacturing plant or a precision robot in a semiconductor fabrication facility, electric actuators provide the necessary motion and control to perform complex tasks with high accuracy.

Process Control

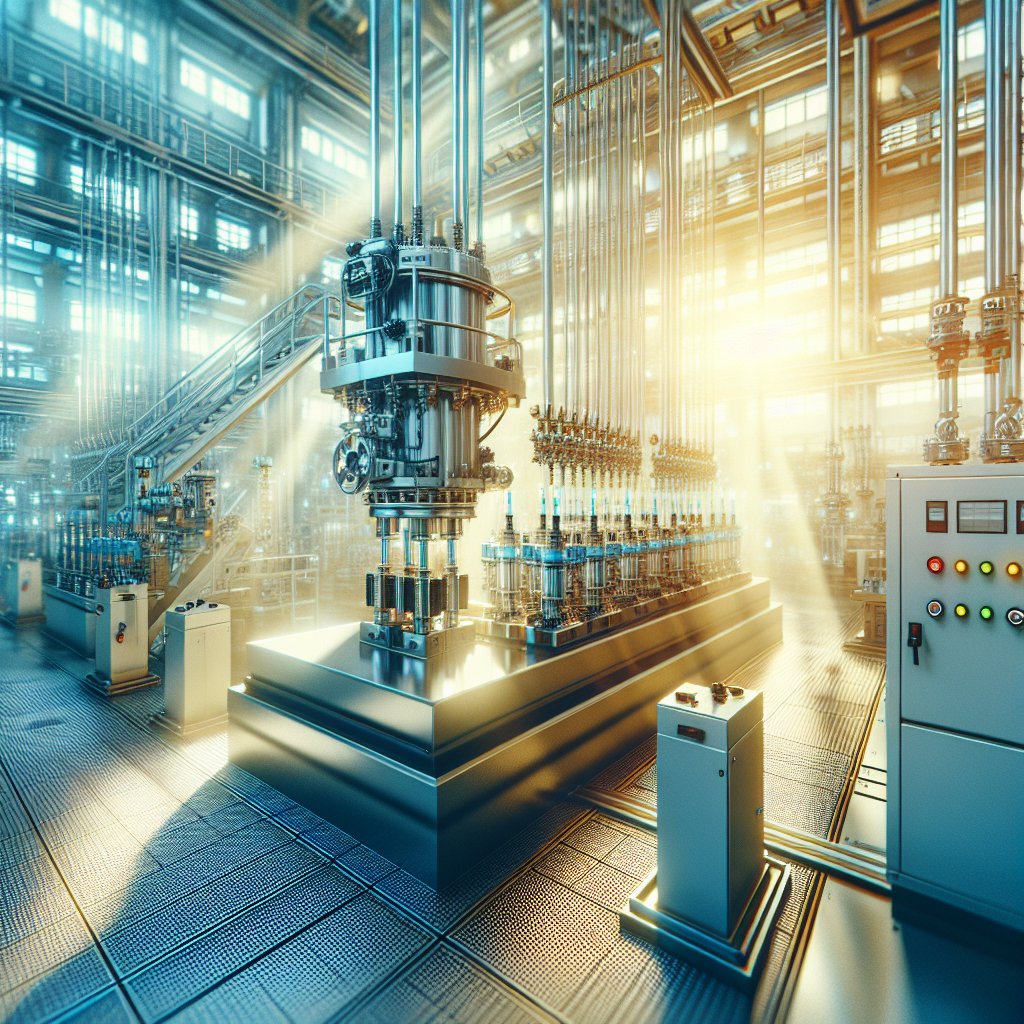

In industries such as oil and gas, chemical processing, and water treatment, electric actuators are used to control valves and regulate the flow of liquids and gases. Their ability to provide precise control and feedback ensures optimal process conditions and enhances safety.

The Future of Electric Actuators in Industrial Automation

As technology continues to advance, the role of electric actuators in industrial automation is set to expand further. Innovations in materials, design, and control systems are paving the way for more efficient and versatile actuators.

Integration with IoT and AI

The integration of electric actuators with the Internet of Things (IoT) and artificial intelligence (AI) is a promising development. IoT connectivity allows for real-time monitoring and control of actuators, enabling predictive maintenance and optimizing performance. AI algorithms can further enhance actuator performance by learning from data and making intelligent adjustments to improve efficiency and accuracy.

Advancements in Materials and Design

Ongoing research into new materials and design techniques is leading to the development of lighter, more durable, and more efficient electric actuators. These advancements will enable actuators to operate in more demanding environments and extend their lifespan, further reducing maintenance costs and downtime.

In conclusion, electric actuators are indispensable components in the field of industrial automation. Their energy efficiency, precision, and low maintenance requirements make them ideal for a wide range of applications. As technology continues to evolve, electric actuators will play an increasingly vital role in driving innovation and efficiency in industrial processes.