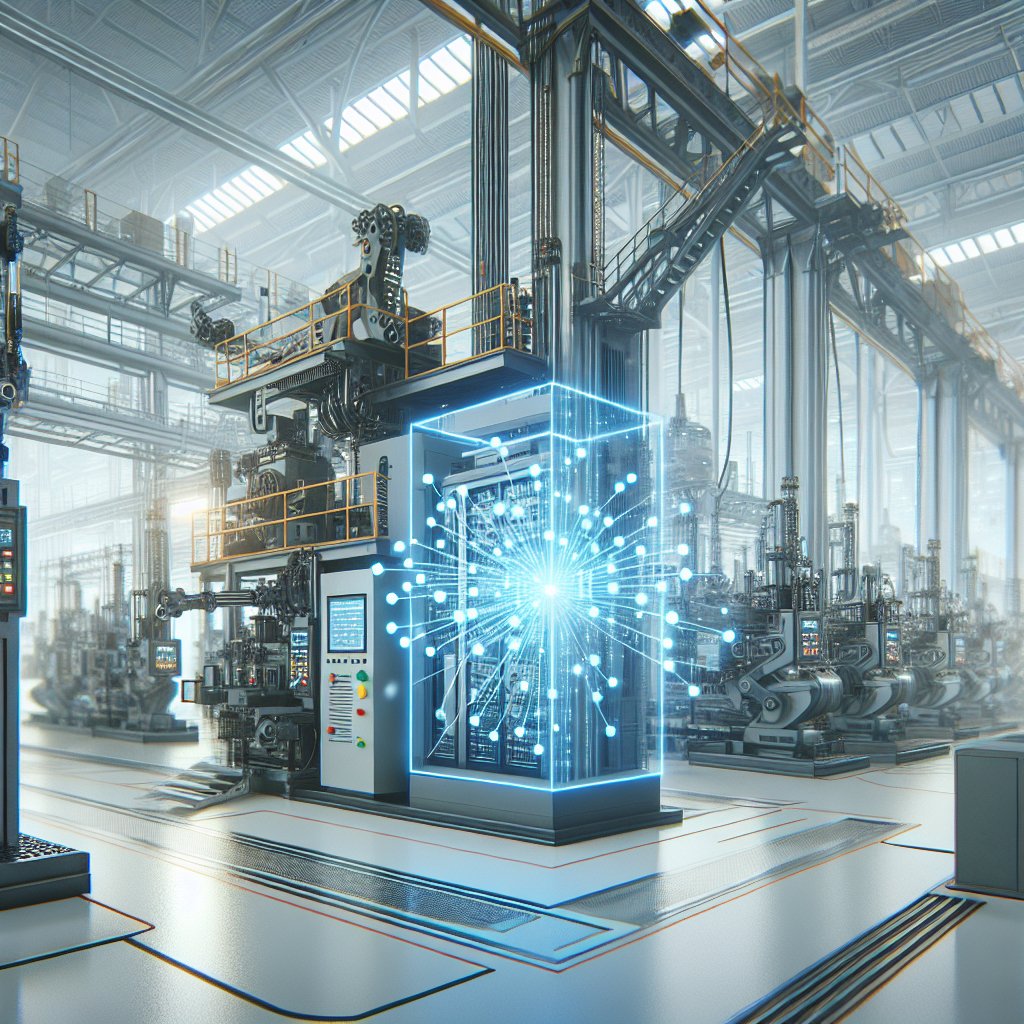

Edge computing is revolutionizing the way industrial machine control systems operate, offering unprecedented levels of efficiency, speed, and reliability. As industries continue to embrace digital transformation, the integration of edge computing into machine control systems is becoming increasingly vital. This article explores the significant role that edge computing plays in enhancing these systems, delving into its benefits, applications, and future potential.

Understanding Edge Computing

Edge computing refers to the practice of processing data closer to the source of data generation, rather than relying on centralized data centers. This approach reduces latency, enhances real-time data processing, and improves the overall performance of industrial systems. In the context of industrial machine control, edge computing enables machines to process data locally, allowing for faster decision-making and more efficient operations.

Key Benefits of Edge Computing

One of the primary advantages of edge computing is its ability to reduce latency. By processing data at the edge of the network, industrial machines can respond to changes in real-time, which is crucial for maintaining optimal performance and avoiding costly downtime. Additionally, edge computing enhances data security by minimizing the need to transmit sensitive information over potentially insecure networks.

Another significant benefit is the reduction in bandwidth usage. By processing data locally, edge computing reduces the amount of data that needs to be sent to centralized data centers, leading to lower operational costs and improved network efficiency. This is particularly important in industrial settings where large volumes of data are generated continuously.

Applications of Edge Computing in Industrial Machine Control

Edge computing is being applied across various industrial sectors to enhance machine control systems. In manufacturing, for example, edge computing enables real-time monitoring and control of production lines, allowing for immediate adjustments to be made in response to changes in demand or production conditions. This leads to increased efficiency and reduced waste.

In the energy sector, edge computing is used to optimize the performance of power generation and distribution systems. By processing data locally, energy companies can quickly identify and address issues, ensuring a stable and reliable power supply. This is particularly important in renewable energy systems, where fluctuations in energy generation can occur rapidly.

Case Studies

Several companies have successfully implemented edge computing in their industrial machine control systems. For instance, a leading automotive manufacturer has integrated edge computing into its production lines, resulting in a 20% increase in production efficiency and a 15% reduction in energy consumption. Similarly, a major utility company has used edge computing to enhance the reliability of its power grid, reducing outages by 30%.

The Future of Edge Computing in Industrial Machine Control

As technology continues to evolve, the role of edge computing in industrial machine control systems is expected to grow. Advances in artificial intelligence and machine learning are likely to further enhance the capabilities of edge computing, enabling even more sophisticated data processing and decision-making at the edge.

Moreover, the increasing adoption of the Internet of Things (IoT) in industrial settings will drive the demand for edge computing solutions. As more devices become connected, the need for efficient data processing and real-time decision-making will become even more critical.

Challenges and Considerations

Despite its many benefits, the implementation of edge computing in industrial machine control systems is not without challenges. One of the primary concerns is the complexity of integrating edge computing solutions with existing infrastructure. Companies must carefully consider their specific needs and capabilities when designing and implementing edge computing systems.

Additionally, there are concerns about data security and privacy. As more data is processed at the edge, companies must ensure that their systems are secure and that sensitive information is protected from unauthorized access.

Conclusion

Edge computing is playing a transformative role in enhancing industrial machine control systems, offering significant benefits in terms of efficiency, speed, and reliability. As industries continue to embrace digital transformation, the integration of edge computing will become increasingly important. By understanding the benefits, applications, and challenges of edge computing, companies can better position themselves to take advantage of this powerful technology and drive their operations forward.