Artificial Intelligence (AI) is revolutionizing the manufacturing industry, bringing unprecedented changes to machinery and production processes. As AI technologies continue to evolve, they are increasingly being integrated into manufacturing systems, leading to enhanced efficiency, reduced costs, and improved product quality. This article explores the profound impact of AI on manufacturing machinery, examining both the opportunities and challenges it presents.

AI-Driven Automation in Manufacturing

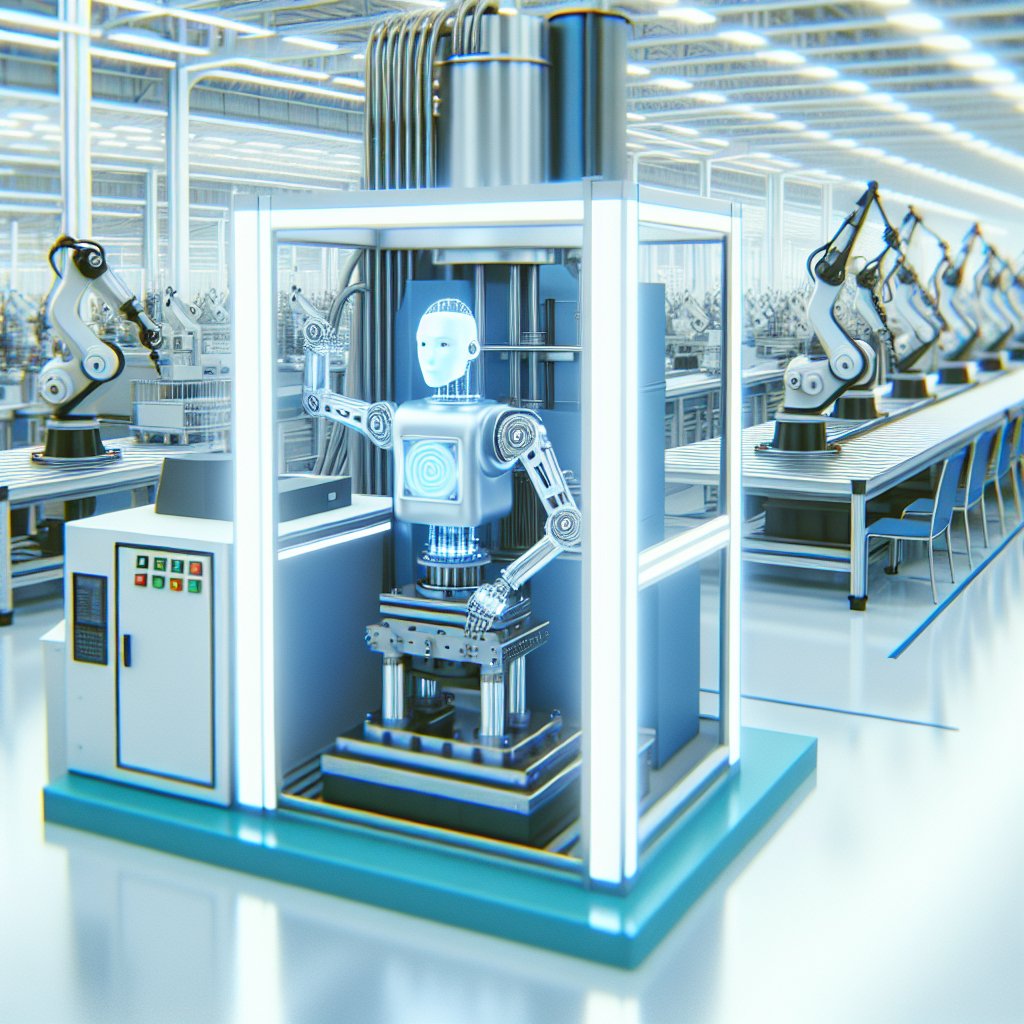

One of the most significant impacts of AI on manufacturing machinery is the advancement of automation. AI-driven automation systems are capable of performing complex tasks with precision and speed that surpass human capabilities. These systems utilize machine learning algorithms to analyze data, make decisions, and execute actions without human intervention.

AI-powered robots and automated machinery are now commonplace in manufacturing plants. They are used for tasks such as assembly, welding, painting, and quality inspection. These machines can work around the clock, increasing production rates and reducing downtime. Moreover, AI systems can learn from data, allowing them to adapt to new tasks and improve their performance over time.

The integration of AI in manufacturing machinery also enhances flexibility. Traditional manufacturing systems are often rigid and require significant reconfiguration to accommodate new products or changes in production processes. In contrast, AI-driven systems can quickly adapt to new requirements, enabling manufacturers to respond swiftly to market demands and reduce time-to-market for new products.

Predictive Maintenance and AI

Another critical area where AI is making a substantial impact is predictive maintenance. Manufacturing machinery is subject to wear and tear, and unexpected breakdowns can lead to costly downtime. AI technologies are being used to predict when machinery is likely to fail, allowing for proactive maintenance and reducing the risk of unexpected disruptions.

AI systems analyze data from sensors embedded in machinery to monitor performance and detect anomalies. By applying machine learning algorithms, these systems can identify patterns and predict potential failures before they occur. This predictive maintenance approach not only minimizes downtime but also extends the lifespan of machinery and reduces maintenance costs.

Furthermore, AI-driven predictive maintenance enhances safety in manufacturing environments. By identifying potential issues before they lead to equipment failure, manufacturers can prevent accidents and ensure a safer working environment for employees.

Quality Control and AI

Quality control is a critical aspect of manufacturing, and AI is playing a pivotal role in enhancing this process. AI technologies are being used to improve the accuracy and efficiency of quality inspections, ensuring that products meet the highest standards before reaching consumers.

AI-powered vision systems are capable of inspecting products at high speeds, identifying defects that may be missed by human inspectors. These systems use deep learning algorithms to recognize patterns and anomalies, allowing them to detect even the smallest imperfections. As a result, manufacturers can achieve higher levels of quality assurance and reduce the risk of defective products reaching the market.

In addition to visual inspections, AI is also being used to analyze data from various stages of the production process. By monitoring parameters such as temperature, pressure, and humidity, AI systems can identify potential quality issues and make real-time adjustments to maintain optimal production conditions.

Challenges and Considerations

While the impact of AI on manufacturing machinery is overwhelmingly positive, it also presents several challenges and considerations. One of the primary concerns is the potential displacement of human workers. As AI-driven automation systems take over tasks traditionally performed by humans, there is a risk of job loss in certain sectors of the manufacturing industry.

To address this challenge, manufacturers must focus on reskilling and upskilling their workforce. By providing training and education programs, companies can help employees transition to new roles that require human skills, such as overseeing AI systems, data analysis, and strategic decision-making.

Another consideration is the ethical use of AI in manufacturing. As AI systems become more autonomous, it is essential to ensure that they operate transparently and fairly. Manufacturers must establish guidelines and standards for the ethical use of AI, addressing issues such as data privacy, bias, and accountability.

The Future of AI in Manufacturing

The future of AI in manufacturing is promising, with continued advancements expected to drive further innovation and transformation. As AI technologies become more sophisticated, they will enable even greater levels of automation, efficiency, and quality in manufacturing processes.

One area of potential growth is the development of collaborative robots, or cobots, which work alongside human workers to enhance productivity and safety. These robots are designed to assist with tasks that require human dexterity and decision-making, creating a harmonious blend of human and machine capabilities.

Additionally, AI is expected to play a crucial role in the development of smart factories, where interconnected systems and devices communicate and collaborate to optimize production. These factories will leverage AI to analyze vast amounts of data, enabling real-time decision-making and continuous improvement.

In conclusion, the impact of AI on manufacturing machinery is profound and far-reaching. By embracing AI technologies, manufacturers can achieve significant gains in efficiency, quality, and flexibility. However, it is essential to address the challenges and considerations associated with AI adoption to ensure a sustainable and ethical future for the manufacturing industry.