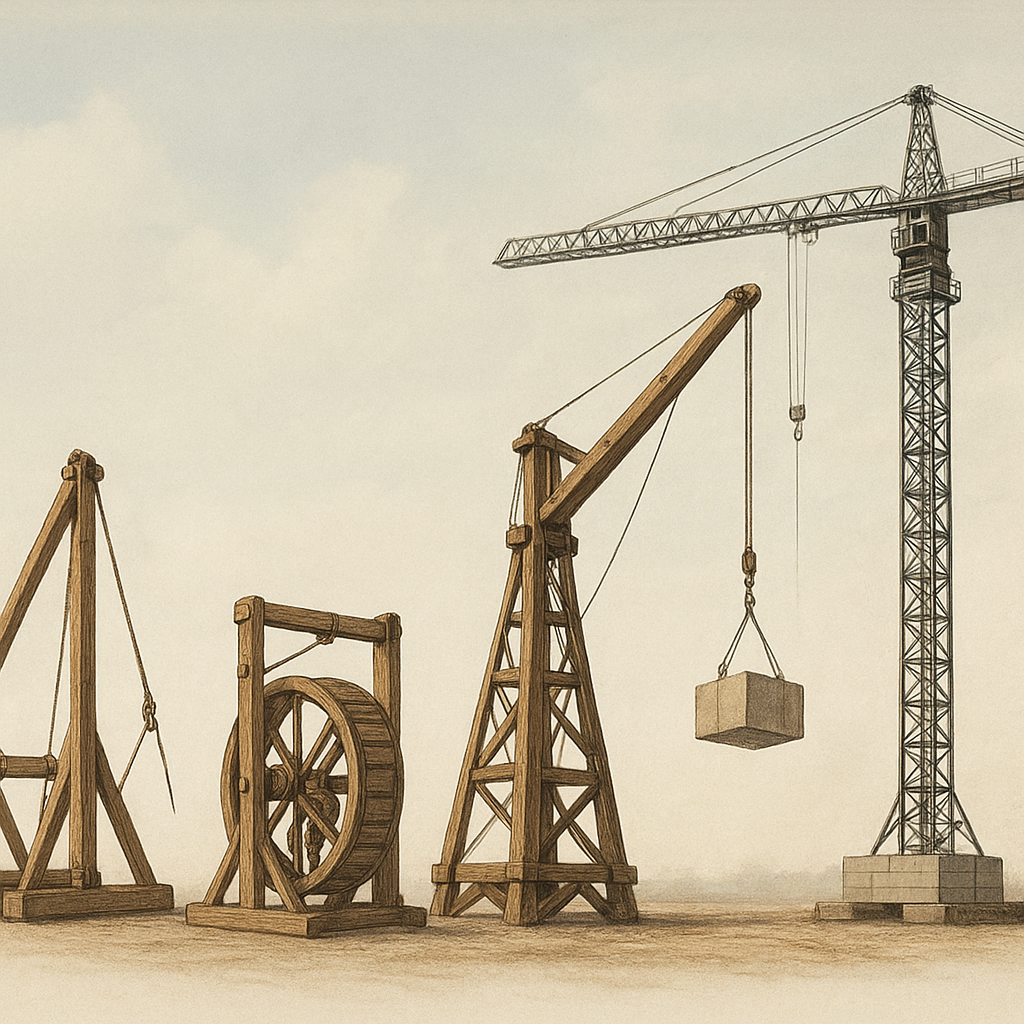

Cranes stand as some of the most remarkable marvels of human ingenuity, blending raw power with precise control. From the earliest pulleys lifted by hand to the towering steel behemoths dotting modern skylines, these machines have continuously reshaped how we build, transport, and innovate. Their evolution mirrors key milestones in engineering history, reflecting our pursuit of greater efficiency, enhanced safety, and relentless automation. This exploration delves into the rich tapestry of lifting technology, charting a course from ancient devices to the digitalized giants that define contemporary construction and industrial landscapes.

Ancient Foundations of Lifting Technology

Long before coal engines hissed and diesel motors roared, civilizations devised clever ways to move heavy loads. The cornerstone was the simple pulley, a wheel with a groove that guided a rope. By combining multiple pulleys into a block-and-tackle system, early builders multiplied mechanical advantage, enabling a small force to lift massive stones.

- Mesopotamian Ziggurats: Laborers used inclined planes and basic capstans to raise bricks and monoliths.

- Egyptian Pyramids: While sledges and lubricated ramps took center stage, pulleys likely assisted in maneuvering cornerstones with precision.

- Greek and Roman Innovations: Archimedes refined screw jacks and compound pulleys, laying the groundwork for rotational force converters.

These early contrivances underscored human ambition to overcome raw material weight. They operated at human or animal pace, emphasizing reliability over speed. Yet their impact was profound, marking the dawn of mechanization and demonstrating how clever design outmatched brute strength.

Industrial Revolution and Mechanization

The 18th and 19th centuries heralded a dramatic leap in lifting machinery. The advent of the steam engine introduced continuous power sources, liberating cranes from manual and animal labor. Dockyards, factories, and rail terminals soon bristled with steam-powered jib cranes, overhead gantries, and traveling portal cranes.

Steam Cranes and Urban Growth

As ports swelled with international trade, nimble steam cranes accelerated cargo handling. Wharfworkers could unload heavy barrels, crates, and machinery in fractions of the time previously required. The synergy of rail connections and crane efficiency fueled unprecedented urban expansion and resource exchange.

Metal Framework and Structural Strength

Iron and early steel replaced timber in crane booms and towers. The stronger materials allowed for higher lifting capacities and longer reaches. Engineers harnessed trusses, girders, and latticework to optimize strength-to-weight ratios, unlocking new architectural possibilities.

- Industrialization accelerated as factories integrated overhead cranes to move raw materials across sprawling workshops.

- Railcar-mounted cranes enhanced track maintenance, repairing rails and replacing sleepers with minimal downtime.

- Urban construction sites employed steam-driven tower cranes to erect iron-framed buildings, precursors to modern skyscrapers.

These cranes symbolized a shift toward systemic productivity, where machinery dictated the tempo of progress. Safety features were rudimentary, often relying on skilled operators who balanced steam pressure and manual brakes. Still, this era set the stage for more sophisticated controls and standardized components.

Modern Giants and Future Trends

Contemporary cranes harness advanced power sources, digital controls, and intelligent monitoring. Electric motors, hydraulics, and hybrid systems deliver unparalleled performance. Towers now ascend hundreds of meters, swinging loads measured in hundreds of tons with pinpoint accuracy.

Hydraulic Precision and Mobility

Hydraulic cylinders transformed crane design by providing smooth, powerful lifting and precise positioning. Mobile cranes on multi-axle trucks offer rapid deployment for diverse job sites—from highway bridges to wind farms. Their telescopic booms extend and retract with remarkable agility, optimizing reach without sacrificing stability.

Digitalization and Smart Operations

Integration of sensors, IoT connectivity, and data analytics drives cranes toward full digitalization. Load moment indicators, real-time diagnostics, and remote-control interfaces enhance safety and reduce downtime. Operators receive feedback on wind speeds, boom angles, and stress points, enabling proactive maintenance strategies that extend equipment lifespan.

- Automation is advancing with AI-guided positioning, where cranes adjust movements to avoid obstacles and maintain balance in dynamic environments.

- Augmented reality overlays assist technicians in assembly, inspection, and repair tasks, streamlining complex procedures.

- Renewable energy integration—such as solar panels on crane cabins—contributes to overall sustainability and lower operational carbon footprints.

Looking ahead, the next wave of innovation may involve collaborative robots (cobots) working alongside human crews, further boosting efficiency and reducing risk in hazardous settings. Modular crane components could simplify transport logistics, while advancements in materials science promise lighter yet stronger structural elements. Ultimately, cranes will remain emblematic of our drive to reach higher, build faster, and embrace the full spectrum of technological innovations.