The world of machinery at work is a testament to human ingenuity, showcasing how advanced engineering can transform industries. From enormous factory robots to compact automated devices, each machine represents a leap forward in innovation and performance. Exploring these marvels reveals the critical role of technology in boosting productivity, ensuring safety, and driving economic growth while addressing global challenges.

Evolution of Industrial Machinery

Early mechanization began with simple steam engines and basic conveyor systems, but modern factories have embraced a new breed of intelligent equipment. The shift from purely mechanical tools to integrated digital systems has elevated production capabilities to unprecedented levels. Engineers now design machines that combine precision, adaptability, and self-diagnosis.

From Steam Power to Smart Lines

- 19th-century steam engines delivered raw power but lacked control and feedback.

- Electrification introduced variable-speed motors and basic automation in the mid-20th century.

- Today’s assembly lines use sensors, actuators, and embedded controllers for real-time adjustments.

Manufacturing plants equipped with connected devices can monitor machine health, predict failures, and optimize workflows to maximize efficiency. This transformation has led to reduced downtime, streamlined maintenance schedules, and significant cost savings.

One underappreciated breakthrough is the adoption of modular machine units. These standardized building blocks allow rapid reconfiguration of production cells, letting factories switch product lines in hours rather than days.

Automation and Robotics in the Workplace

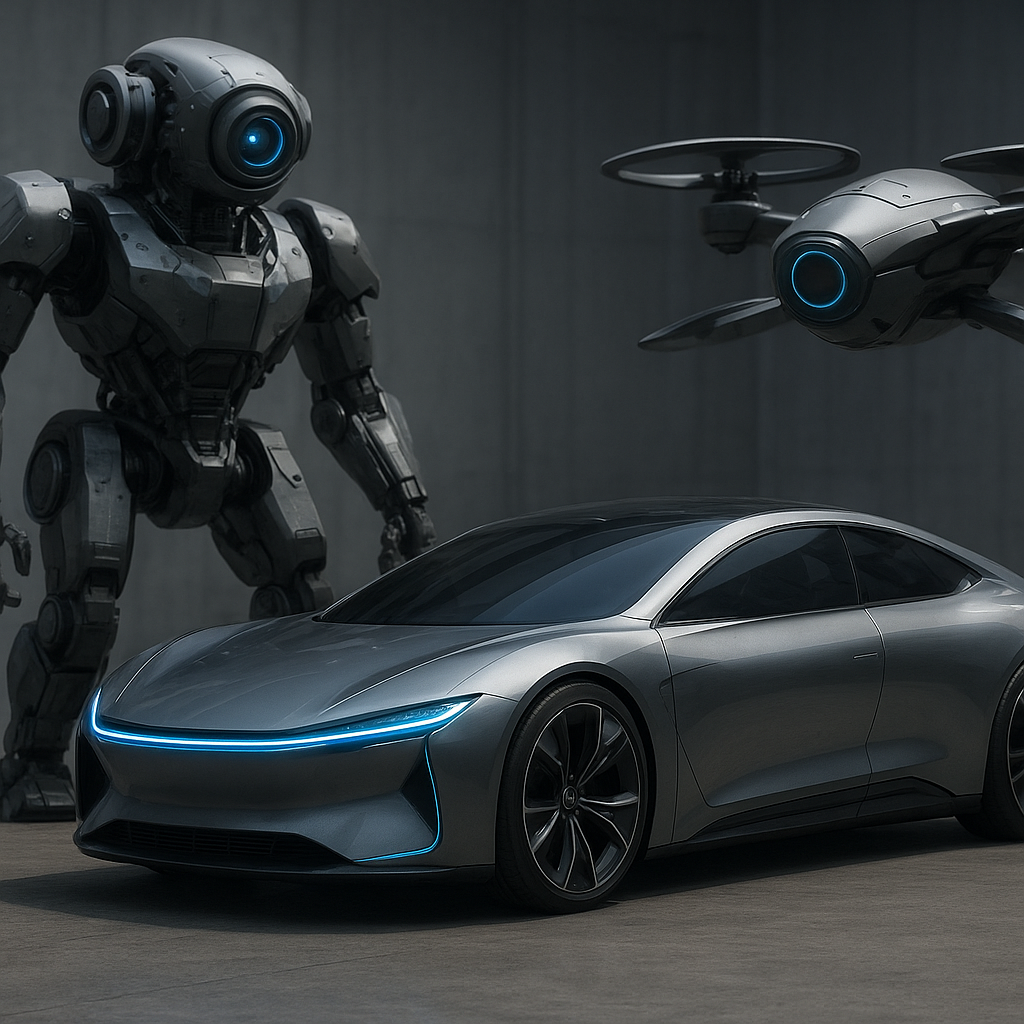

Automation has revolutionized both heavy industries and service sectors. Robots now perform tasks once thought impossible to automate, from delicate electronics assembly to heavy-lifting in warehouses. The integration of robotics and AI enables machines to learn, adapt, and collaborate safely with human coworkers.

Collaborative Robots (Cobots)

- Designed to work side by side with humans without extensive safety barriers.

- Equipped with force sensors and vision systems to avoid collisions.

- Ideal for tasks requiring a blend of manual dexterity and repetitive work.

Cobots bring flexibility to production lines. They can be redeployed for different tasks in minutes, reducing the need for specialized machinery. By handling repetitive or dangerous jobs, they free human operators to focus on creative and supervisory roles.

Meanwhile, large-scale automated systems handle bulk materials, sorting, and shipping with astounding speed. Automated Guided Vehicles (AGVs) and drones navigate warehouses using advanced mapping technologies, ensuring that products move seamlessly from storage to delivery. These systems rely on machine vision and real-time data streams to make split-second decisions.

Sustainable Designs Shaping the Future

Environmental concerns have pushed engineers to rethink machine design from the ground up. Sustainability is no longer an afterthought but a core requirement. Machines now feature energy recovery systems, eco-friendly materials, and software that minimizes waste. The goal is to achieve a balance between productivity and environmental stewardship.

Energy-Efficient Drives and Green Materials

- Regenerative braking in electric motors captures kinetic energy and feeds it back into the grid.

- Advanced composites and recycled alloys reduce the ecological footprint of heavy machinery.

- Smart control algorithms optimize power consumption based on production demands.

These improvements contribute to a substantial reduction in carbon emissions. Factories implementing green technology often experience lower operational costs due to reduced energy bills and tax incentives for sustainable practices.

Additionally, the rise of sustainability-focused certifications has created a competitive landscape where companies strive to outdo each other in eco-friendly innovation. This trend drives rapid development of new materials and manufacturing methods that promise cleaner, smarter processes.

Innovative Materials and Manufacturing Techniques

Traditional steel and aluminum are being complemented by advanced alloys, polymers, and even nanomaterials. These substances offer unmatched durability, corrosion resistance, and strength-to-weight ratios. Combined with cutting-edge fabrication methods, they are redefining what machines can achieve.

3D Printing and Additive Manufacturing

- Layer-by-layer construction allows for complex geometries unachievable by casting or machining.

- Minimal material waste and shorter supply chains reduce lead times.

- On-demand production permits rapid prototyping and small-batch customization.

Industries from aerospace to healthcare leverage additive techniques to create bespoke components. Turbine blades with intricate cooling channels, patient-specific implants, and acoustic sensors built into structural parts showcase the versatility of these methods.

Moreover, hybrid manufacturing centers merge subtractive and additive processes in a single platform, enabling the production of high-precision parts with embedded sensors or complex internal features. This convergence enhances both precision and design freedom.

Connectivity and the Rise of Cyber-Physical Systems

The Industrial Internet of Things (IIoT) connects machines, sensors, and control systems through high-speed networks, creating a holistic digital ecosystem. This interconnected environment, often called a cyber-physical system, empowers factories to function as cohesive, intelligent entities.

Real-Time Monitoring and Predictive Maintenance

- Vibration, temperature, and acoustic sensors track equipment health continuously.

- Data analytics platforms predict component fatigue and schedule maintenance proactively.

- Cloud-based dashboards provide managers with actionable insights from remote locations.

Connectivity also enables collaborative supply chains, where inventory levels trigger automatic orders, and logistics are synchronized to minimize delays. Such integration enhances overall connectivity and fosters more resilient operations.

Human-Machine Interaction and Safety Innovations

As machines become more capable, ensuring safe human interaction is paramount. Advanced safety systems combine force-limited actuators, proximity sensors, and AI-driven supervision. These safeguards prevent accidents and allow for smoother collaboration.

Virtual and Augmented Reality in Maintenance

- Technicians use AR headsets to overlay instructions and 3D models onto real equipment.

- Remote experts can guide on-site staff through complex procedures in real time.

- Virtual simulations help train operators on new machines before they hit the factory floor.

Such tools improve training effectiveness and reduce the risk of human error during setup and repairs. They also shorten downtime by providing instant access to schematics and part catalogs.

Challenges and the Road Ahead

Despite remarkable progress, engineers face hurdles such as cybersecurity threats, workforce reskilling, and the need for global standards. Balancing rapid technological adoption with ethical and social considerations remains a complex task. Yet, continuous advancements in automation and the broader digital transformation promise to address these issues.

Ultimately, the machines at work today are harbingers of an even more connected, intelligent, and sustainable industrial landscape. Embracing these technologies will be crucial for businesses aiming to thrive in an increasingly competitive global market.