Retrofitting industrial equipment with advanced technology is a transformative approach that offers numerous benefits to businesses seeking to enhance efficiency, reduce costs, and improve sustainability. As industries evolve, the integration of cutting-edge technology into existing machinery becomes a strategic move to stay competitive and meet the demands of modern production environments. This article explores the various advantages of retrofitting industrial equipment, highlighting how it can lead to significant improvements in operational performance and environmental impact.

Enhancing Operational Efficiency

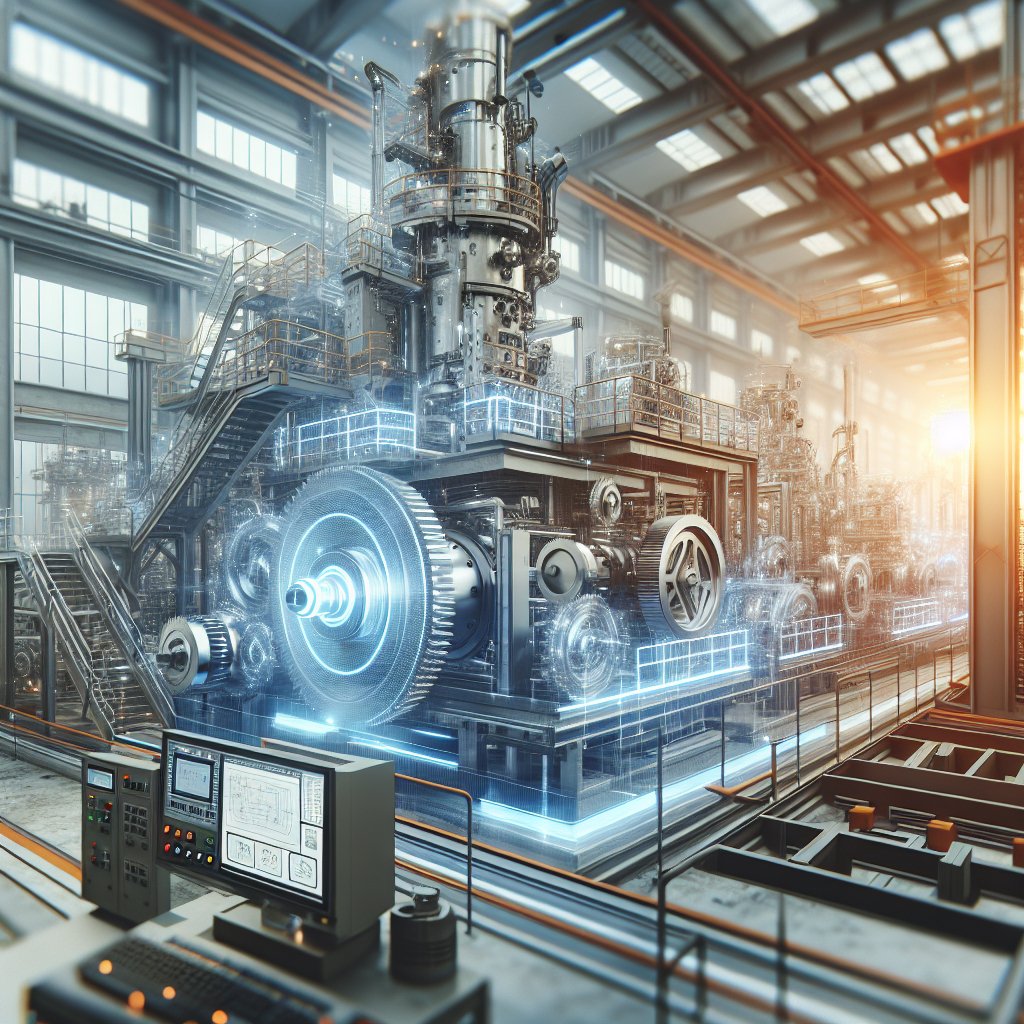

One of the primary benefits of retrofitting industrial equipment with advanced technology is the significant enhancement of operational efficiency. By upgrading existing machinery with modern components and systems, businesses can optimize their production processes and achieve higher levels of productivity. Advanced technologies such as automation, IoT (Internet of Things), and AI (Artificial Intelligence) can be integrated into older equipment, allowing for more precise control, monitoring, and data analysis.

Automation, for instance, can streamline repetitive tasks, reduce human error, and increase the speed of production. This not only boosts output but also frees up human resources to focus on more complex and value-added activities. IoT-enabled devices can provide real-time data on equipment performance, enabling predictive maintenance and reducing downtime. By identifying potential issues before they lead to equipment failure, companies can avoid costly disruptions and extend the lifespan of their machinery.

Moreover, AI-driven analytics can offer insights into production trends and inefficiencies, allowing businesses to make informed decisions and optimize their operations. By leveraging these technologies, companies can achieve a more agile and responsive production environment, capable of adapting to changing market demands and customer needs.

Cost Reduction and Resource Optimization

Retrofitting industrial equipment with advanced technology also presents significant opportunities for cost reduction and resource optimization. By upgrading existing machinery rather than investing in entirely new systems, businesses can achieve substantial savings on capital expenditures. Retrofitting allows companies to leverage their existing assets while still benefiting from the latest technological advancements.

In addition to reducing capital costs, retrofitting can lead to lower operational expenses. Advanced technologies often come with improved energy efficiency, reducing the overall energy consumption of industrial processes. This not only lowers utility bills but also contributes to a smaller carbon footprint, aligning with sustainability goals and regulatory requirements.

Furthermore, the integration of smart technologies can optimize the use of raw materials and resources. For example, precision sensors and control systems can minimize waste and ensure that materials are used more efficiently. This not only reduces costs but also enhances the sustainability of production processes, making them more environmentally friendly.

Overall, retrofitting industrial equipment with advanced technology is a strategic investment that can yield significant returns in terms of cost savings and resource optimization. By embracing these innovations, businesses can enhance their competitiveness and position themselves for long-term success in an increasingly dynamic and demanding market.

Improving Sustainability and Environmental Impact

In today’s world, sustainability is a critical consideration for businesses across all industries. Retrofitting industrial equipment with advanced technology can play a crucial role in improving the environmental impact of production processes. By upgrading machinery to be more energy-efficient and resource-conscious, companies can significantly reduce their carbon footprint and contribute to a more sustainable future.

Advanced technologies such as energy-efficient motors, variable frequency drives, and smart sensors can optimize energy consumption and reduce greenhouse gas emissions. These upgrades not only align with environmental regulations but also enhance the company’s reputation as a responsible and sustainable business. Additionally, by minimizing waste and optimizing resource use, retrofitting can help companies achieve their sustainability targets and meet the expectations of environmentally conscious consumers.

Moreover, the integration of IoT and AI technologies can enable more effective monitoring and management of environmental impact. Real-time data on energy usage, emissions, and resource consumption can provide valuable insights for continuous improvement and sustainability reporting. By leveraging these technologies, businesses can demonstrate their commitment to environmental stewardship and gain a competitive edge in the market.

Conclusion

Retrofitting industrial equipment with advanced technology offers a multitude of benefits that can transform the way businesses operate. From enhancing operational efficiency and reducing costs to improving sustainability and environmental impact, the advantages of retrofitting are clear. By embracing these innovations, companies can optimize their production processes, achieve significant cost savings, and contribute to a more sustainable future. As industries continue to evolve, retrofitting will remain a vital strategy for businesses seeking to stay competitive and meet the demands of a rapidly changing world.