The integration of advanced machinery in modern workplaces has catalyzed a profound transformation across multiple industries. Harnessing robotics and automation, companies optimize processes, reduce costs, and elevate product quality to unprecedented levels. This article explores the evolution, core technologies, workforce implications, and future prospects of machines at work.

The Evolution of Industrial Machinery

The journey of machines in manufacturing began with the first steam engines and textile looms. Over time, mechanical innovations progressed from simple hydraulics to complex programmable logic controllers (PLCs). By the late 20th century, the advent of industrial robots marked a pivotal shift. These early robots performed repetitive tasks such as welding and painting, delivering consistent output with high precision.

Key milestones in this evolution include:

- Introduction of numerical control (NC) in the 1950s

- Rise of computer numerical control (CNC) in the 1970s

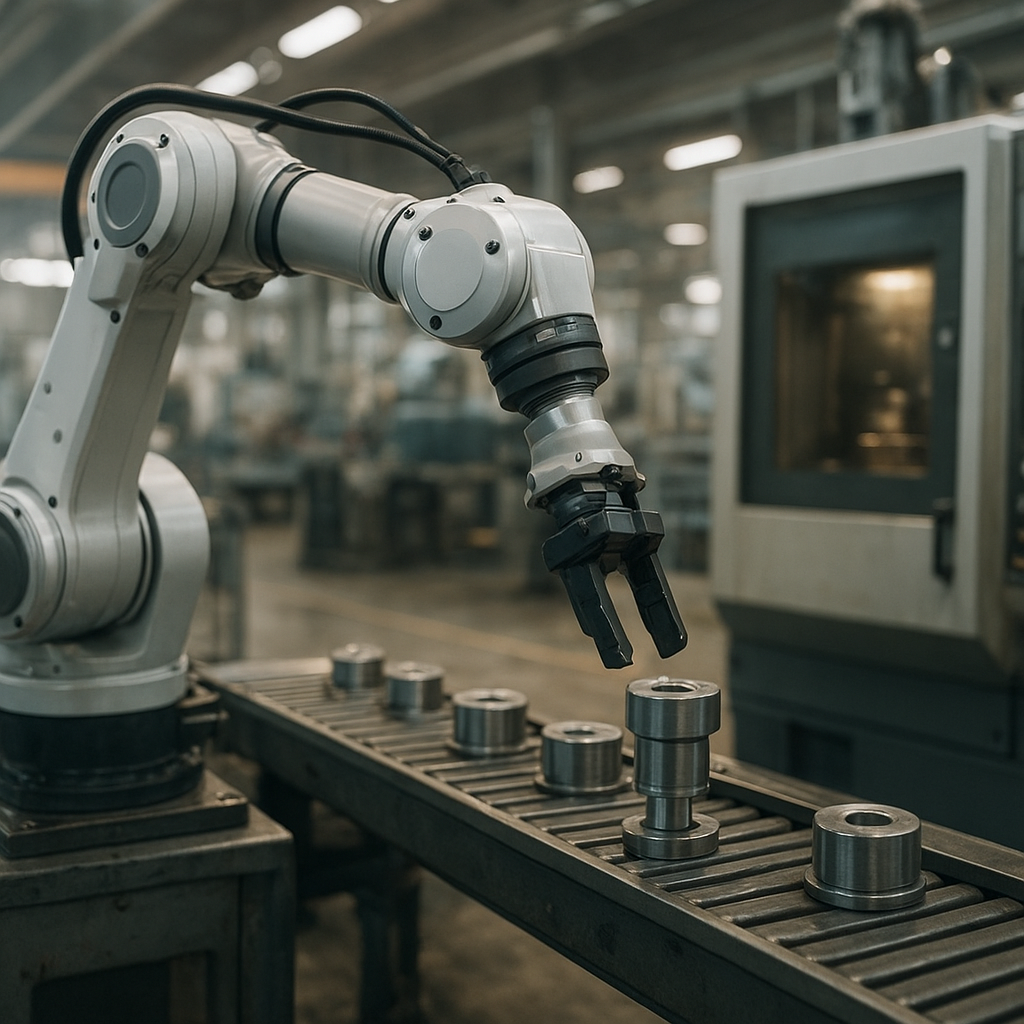

- Deployment of articulated robots during the 1980s

- Integration of digital networks and data analytics in the 2000s

With each development, the footprint of machines grew in both size and intelligence. Today’s manufacturing floors host collaborative robots (cobots) that work side by side with human operators, enabling complex assembly tasks that once required manual dexterity.

Key Technologies Driving Automation

Several breakthrough technologies underpin the rapid expansion of machine-led operations:

- Artificial Intelligence: AI algorithms analyze real-time data streams to optimize production schedules and predict equipment failures.

- Machine Learning: Learning models improve quality control by identifying defects faster than human inspectors.

- Internet of Things: IoT sensors network machines, enabling seamless integration and remote monitoring.

- Computer Vision: High-resolution cameras combined with image processing detect flaws and guide robotic arms with micron-level accuracy.

- Additive Manufacturing: 3D printing builds complex parts layer by layer, reducing material waste and lead times.

These technologies converge within smart factories—factories where every machine communicates performance metrics to a central platform. Managers gain unprecedented visibility into throughput, energy consumption, and maintenance schedules, leading to more informed decisions.

Impact on Workforce and Efficiency

The rise of robots has sparked debates on job displacement. While machines assume repetitive or dangerous roles, human workers shift toward supervisory, programming, and maintenance functions. Key impacts include:

- Enhanced safety: Robots handle hazardous tasks such as heavy lifting, toxic material handling, and hot environments.

- Skill transformation: Workers gain new competencies in robotics programming, data analysis, and systems integration.

- Productivity gains: Automated lines operate 24/7 with minimal downtime, boosting overall output and reducing per-unit costs.

- Quality consistency: Machines adhere to exact specifications, minimizing defects and rework volumes.

Organizations investing in workforce retraining foster a culture of innovation and continuous improvement. Apprenticeships and certification programs prepare technicians to oversee sophisticated machinery, ensuring a balanced human–machine collaboration.

Sustainability and Resource Optimization

Environmental concerns drive manufacturers to adopt sustainable solutions. Automated systems precisely meter raw materials, preventing overuse and waste. Predictive maintenance algorithms reduce unplanned downtime and extend equipment life, cutting energy consumption. Examples include:

- Energy-efficient servo motors that adjust power based on load requirements

- Closed-loop cooling systems that recycle coolant fluids

- Automated sorting lines that separate recyclable materials on-site

By embracing green automation strategies, companies achieve compliance with stringent regulations and appeal to eco-conscious stakeholders. This holistic approach underscores the synergy between technology and environmental stewardship.

Future Trends and Challenges

Looking ahead, several trends will shape the next generation of machine-centric workplaces:

- Edge computing: Processing data at the machine level for faster decision-making and reduced network loads.

- Digital twins: Virtual replicas of production lines to simulate changes before physical implementation.

- Collaborative AI: Enhanced human–robot teams where machines learn from human behavior and adapt dynamically.

- Blockchain for traceability: Immutable ledgers that verify part origins and production steps in regulated industries.

Despite these opportunities, challenges persist. Cybersecurity risks escalate as connectivity widens the attack surface. High initial investment costs can deter small and medium enterprises. Moreover, regulatory frameworks struggle to keep pace with rapid innovation.

Addressing these barriers demands cross-industry collaboration, standardized protocols, and targeted investments in research and workforce development. By navigating these hurdles, manufacturers can unlock the full potential of reliability, efficiency, and competitive advantage offered by advanced machines.