Augmented Reality (AR) is revolutionizing the way industrial training programs are conducted, offering immersive and interactive experiences that enhance learning and skill acquisition. By overlaying digital information onto the physical world, AR provides trainees with a unique opportunity to engage with complex machinery and processes in a safe and controlled environment. This article explores the transformative impact of AR on industrial training, highlighting its benefits, applications, and future potential.

The Benefits of Augmented Reality in Industrial Training

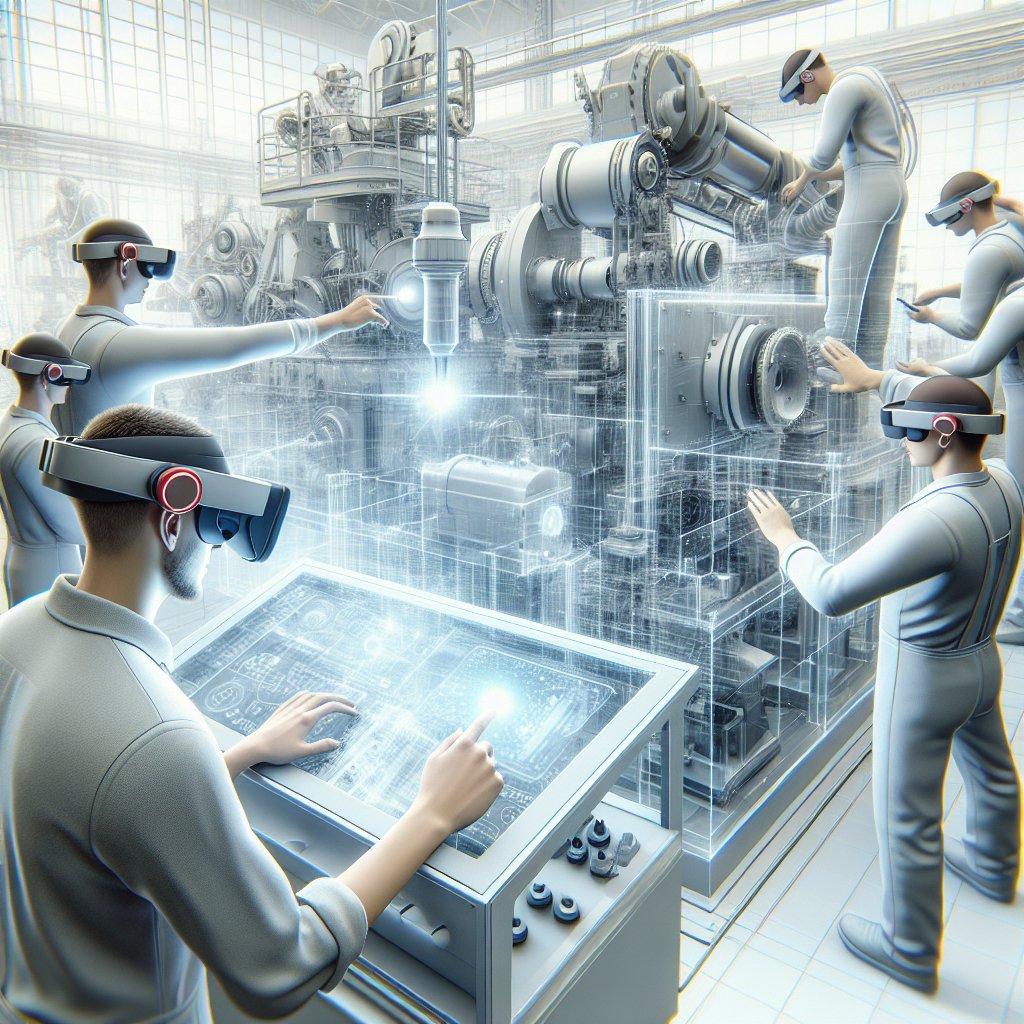

One of the primary advantages of using Augmented Reality in industrial training is its ability to create a highly engaging and interactive learning experience. Traditional training methods often rely on static materials such as manuals and videos, which can be difficult for trainees to relate to real-world applications. AR, on the other hand, allows trainees to visualize and interact with 3D models of equipment and systems, providing a hands-on experience that enhances understanding and retention.

Moreover, AR can significantly reduce the time and cost associated with training. By simulating real-world scenarios, AR eliminates the need for physical prototypes and reduces the risk of damage to expensive equipment. Trainees can practice and make mistakes in a virtual environment without any real-world consequences, leading to faster learning curves and increased confidence.

Another key benefit of AR in industrial training is its ability to provide personalized learning experiences. AR systems can be tailored to the individual needs of each trainee, offering customized content and feedback based on their performance. This adaptability ensures that trainees receive the most relevant and effective training, improving overall competency and productivity.

Applications of Augmented Reality in Industrial Training

Augmented Reality is being applied across various industries to enhance training programs, from manufacturing and construction to healthcare and aerospace. In the manufacturing sector, AR is used to train workers on assembly lines, guiding them through complex procedures with step-by-step instructions overlaid onto their field of view. This not only improves accuracy and efficiency but also reduces the likelihood of errors and accidents.

In the construction industry, AR is employed to train workers on site safety and equipment operation. By simulating hazardous scenarios, trainees can learn how to respond to emergencies and avoid potential dangers. AR also aids in visualizing architectural plans and designs, allowing workers to better understand project layouts and specifications.

The healthcare industry is another area where AR is making significant strides in training. Medical professionals can use AR to practice surgical procedures, visualize anatomy, and learn about new medical devices. This technology provides a risk-free environment for honing skills and improving patient outcomes.

In the aerospace sector, AR is used to train pilots and maintenance crews. Pilots can practice flight maneuvers and emergency protocols in a virtual cockpit, while maintenance personnel can learn how to inspect and repair aircraft components with the help of AR overlays. This ensures that all personnel are well-prepared and equipped to handle real-world challenges.

Challenges and Future Potential of Augmented Reality in Industrial Training

Despite its numerous benefits, the implementation of Augmented Reality in industrial training is not without challenges. One of the main obstacles is the high cost of AR hardware and software, which can be prohibitive for some organizations. Additionally, there is a learning curve associated with adopting new technologies, and some trainees may require additional support to become comfortable with AR systems.

Another challenge is the need for high-quality content that accurately represents real-world scenarios. Developing detailed and realistic AR simulations requires significant time and resources, and organizations must ensure that their content is regularly updated to reflect the latest industry standards and practices.

Looking to the future, the potential of Augmented Reality in industrial training is vast. As technology continues to advance, AR systems are expected to become more affordable and accessible, enabling wider adoption across industries. The integration of artificial intelligence and machine learning with AR could further enhance training programs by providing real-time analytics and adaptive learning experiences.

In conclusion, Augmented Reality is poised to transform industrial training programs by offering immersive, interactive, and personalized learning experiences. While challenges remain, the benefits of AR in terms of engagement, efficiency, and safety make it a valuable tool for organizations seeking to enhance their training initiatives. As the technology continues to evolve, its impact on industrial training is likely to grow, paving the way for a more skilled and competent workforce.