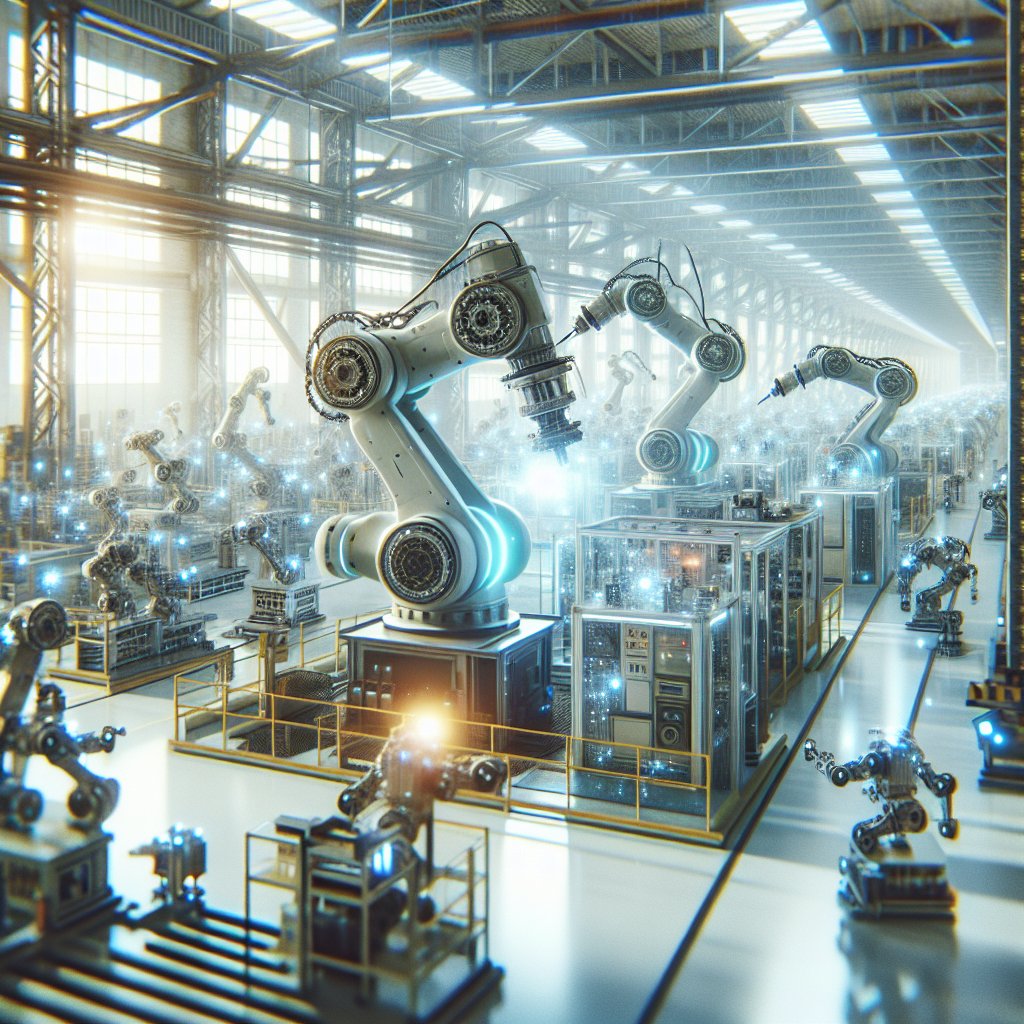

Artificial Intelligence (AI) has been a game-changer in various industries, and its integration with robotics is revolutionizing productivity in factories. The synergy between AI and robotics is not just a futuristic concept but a present-day reality that is transforming manufacturing processes, enhancing efficiency, and reducing operational costs. This article delves into how AI-powered robots are reshaping the landscape of factory productivity, exploring the technological advancements and the implications for the workforce.

The Rise of AI-Powered Robotics in Manufacturing

The advent of AI-powered robotics in manufacturing has marked a significant shift from traditional production methods. These robots are equipped with advanced algorithms that enable them to perform complex tasks with precision and speed. Unlike their predecessors, which required extensive programming for each task, AI-powered robots can learn and adapt to new tasks through machine learning techniques. This adaptability is crucial in a dynamic manufacturing environment where product lines and processes frequently change.

One of the key advantages of AI-powered robots is their ability to process vast amounts of data in real-time. This capability allows them to make informed decisions quickly, optimizing production lines and minimizing downtime. For instance, AI algorithms can predict equipment failures before they occur, allowing for proactive maintenance and reducing costly interruptions. Additionally, these robots can work alongside human workers, taking on repetitive and hazardous tasks, thereby improving workplace safety and allowing human employees to focus on more strategic roles.

Enhancing Efficiency and Reducing Costs

AI-powered robots are instrumental in enhancing efficiency within factories. By automating routine tasks, these robots free up human workers to engage in more complex and creative problem-solving activities. This shift not only boosts productivity but also leads to higher job satisfaction among employees, as they are no longer burdened with monotonous tasks.

Moreover, AI-powered robots contribute to significant cost reductions. They operate with high precision, reducing material waste and ensuring consistent product quality. This precision is particularly beneficial in industries such as electronics and automotive manufacturing, where even minor defects can lead to substantial financial losses. Furthermore, the ability of AI-powered robots to work around the clock without fatigue or errors translates into increased output and faster turnaround times, providing companies with a competitive edge in the market.

Another cost-saving aspect of AI-powered robotics is their role in predictive maintenance. By continuously monitoring equipment performance, these robots can identify potential issues before they escalate into major problems. This proactive approach not only extends the lifespan of machinery but also minimizes the need for expensive emergency repairs, ultimately leading to more efficient use of resources and a healthier bottom line for manufacturers.

Implications for the Workforce

The integration of AI-powered robots in factories has sparked discussions about the future of the workforce. While there are concerns about job displacement, the reality is more nuanced. AI-powered robots are not replacing human workers but rather augmenting their capabilities. By taking over repetitive and dangerous tasks, these robots allow human employees to focus on roles that require critical thinking, creativity, and emotional intelligence—skills that are uniquely human and difficult to replicate with machines.

Furthermore, the rise of AI-powered robotics is creating new job opportunities in areas such as robot maintenance, programming, and data analysis. As factories become more technologically advanced, there is a growing demand for skilled workers who can manage and optimize these sophisticated systems. This shift necessitates a focus on reskilling and upskilling the workforce to ensure that employees are equipped to thrive in an AI-driven manufacturing environment.

In conclusion, AI-powered robots are playing a pivotal role in enhancing productivity in factories. By automating routine tasks, improving efficiency, and reducing costs, these robots are transforming the manufacturing landscape. While there are challenges to address, particularly concerning workforce adaptation, the potential benefits of AI-powered robotics in factories are immense. As technology continues to evolve, the collaboration between humans and robots will likely become even more integral to the success of manufacturing operations worldwide.