Collaborative robots, often referred to as cobots, are revolutionizing the healthcare equipment manufacturing industry by enhancing efficiency, precision, and safety. As the demand for advanced medical devices continues to grow, the integration of cobots into manufacturing processes is becoming increasingly vital. This article delves into the transformative role of collaborative robots in the production of healthcare equipment, highlighting their benefits, applications, and future potential.

The Rise of Collaborative Robots in Manufacturing

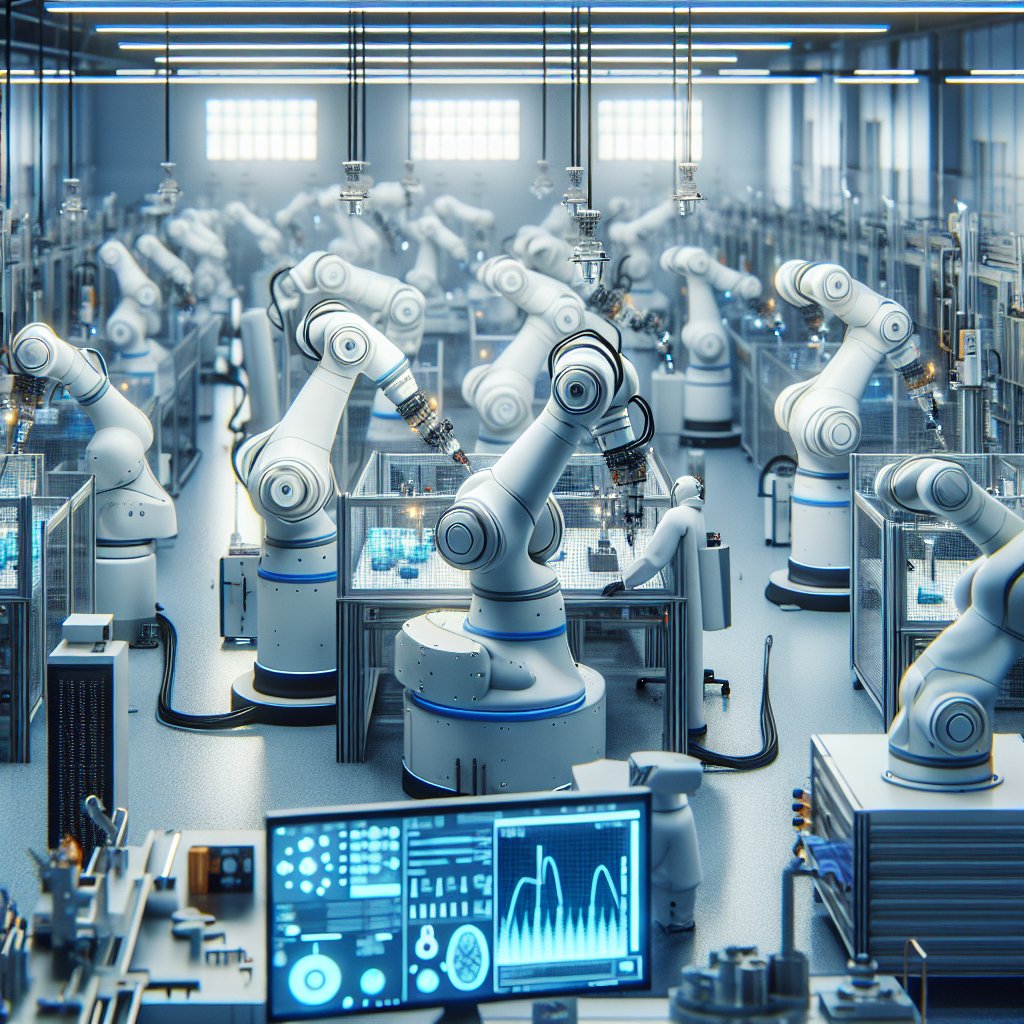

The advent of collaborative robots marks a significant shift in the manufacturing landscape. Unlike traditional industrial robots, which are typically isolated from human workers due to safety concerns, cobots are designed to work alongside humans in a shared workspace. This capability opens up new possibilities for automation in industries where human dexterity and decision-making are crucial, such as healthcare equipment manufacturing.

One of the primary advantages of cobots is their ability to perform repetitive and precise tasks with high accuracy. In the context of healthcare equipment manufacturing, this means that cobots can handle tasks such as assembly, quality control, and packaging with minimal error rates. This not only improves the overall quality of the products but also reduces the time and cost associated with manual labor.

Moreover, cobots are equipped with advanced sensors and machine learning algorithms that enable them to adapt to changing environments and tasks. This flexibility is particularly beneficial in the healthcare sector, where the production of equipment often requires customization and adherence to strict regulatory standards. By leveraging the capabilities of cobots, manufacturers can ensure that their products meet the necessary quality and safety requirements while maintaining high levels of productivity.

Applications of Cobots in Healthcare Equipment Manufacturing

The integration of collaborative robots into healthcare equipment manufacturing processes has led to numerous applications that enhance efficiency and innovation. One notable application is in the assembly of complex medical devices, such as surgical instruments and diagnostic equipment. Cobots can perform intricate assembly tasks with precision, reducing the likelihood of defects and ensuring that the final products meet stringent quality standards.

In addition to assembly, cobots are also being used for quality control and inspection purposes. Equipped with advanced vision systems, cobots can detect defects and inconsistencies in products with a high degree of accuracy. This capability is crucial in the healthcare industry, where even minor defects can have significant implications for patient safety. By automating the inspection process, manufacturers can ensure that their products are free from defects and comply with regulatory requirements.

Another area where cobots are making a significant impact is in the packaging and logistics of healthcare equipment. Cobots can handle tasks such as sorting, packing, and labeling with speed and precision, streamlining the supply chain and reducing the risk of errors. This is particularly important in the healthcare sector, where timely and accurate delivery of equipment is essential for patient care.

Enhancing Safety and Collaboration

One of the key benefits of collaborative robots is their ability to enhance safety in the workplace. Cobots are designed with built-in safety features, such as force sensors and emergency stop functions, that allow them to operate safely alongside human workers. This reduces the risk of accidents and injuries, creating a safer working environment for employees.

Furthermore, the collaborative nature of cobots fosters a more harmonious relationship between humans and machines. By taking on repetitive and physically demanding tasks, cobots free up human workers to focus on more complex and creative aspects of the manufacturing process. This not only improves job satisfaction but also leads to higher levels of innovation and productivity.

The Future of Cobots in Healthcare Equipment Manufacturing

As technology continues to advance, the role of collaborative robots in healthcare equipment manufacturing is expected to grow even further. With the development of more sophisticated sensors, artificial intelligence, and machine learning algorithms, cobots will become increasingly capable of handling complex tasks and adapting to dynamic environments.

In the future, we can expect to see cobots playing a more prominent role in the customization and personalization of healthcare equipment. As the demand for personalized medical devices continues to rise, cobots will be instrumental in enabling manufacturers to produce tailored solutions that meet the unique needs of individual patients.

Moreover, the integration of cobots with other emerging technologies, such as the Internet of Things (IoT) and blockchain, will further enhance their capabilities and applications. By leveraging these technologies, manufacturers can create more efficient, transparent, and secure supply chains, ultimately improving the quality and accessibility of healthcare equipment.

In conclusion, collaborative robots are transforming the healthcare equipment manufacturing industry by enhancing efficiency, precision, and safety. As the demand for advanced medical devices continues to grow, the integration of cobots into manufacturing processes will become increasingly vital. By embracing this technology, manufacturers can ensure that they remain competitive in a rapidly evolving industry, ultimately improving patient care and outcomes.