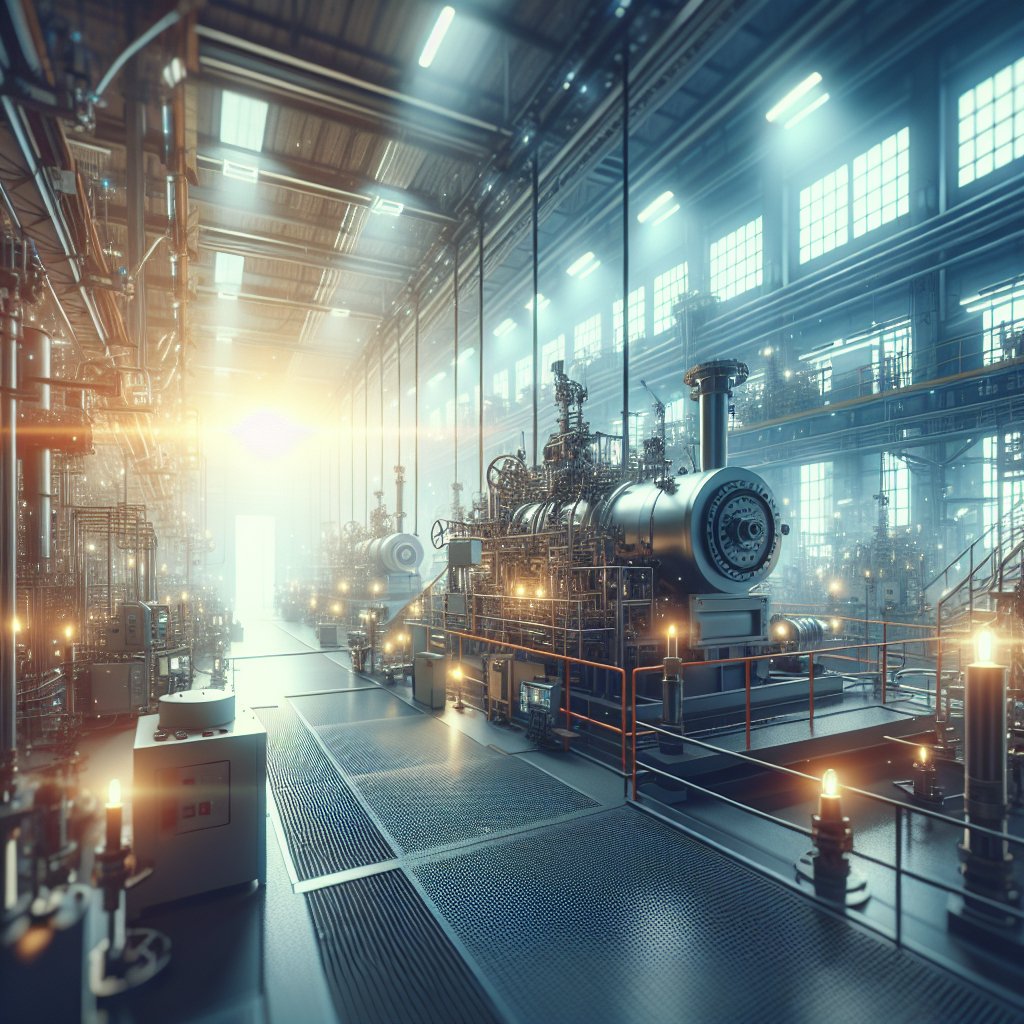

Industrial lubrication technologies have undergone significant advancements in recent years, revolutionizing the way industries maintain and enhance the performance of machinery. These innovations are crucial for reducing friction, minimizing wear and tear, and ensuring the longevity of equipment. In this article, we will delve into the latest developments in industrial lubrication, exploring how these technologies are transforming various sectors and contributing to more efficient and sustainable operations.

Understanding the Basics of Industrial Lubrication

Before diving into the innovations, it’s essential to understand the fundamental role of lubrication in industrial settings. Lubricants are substances applied to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. This process is vital in machinery, where components are in constant motion and subject to wear and tear.

Traditionally, lubricants have been derived from mineral oils, but the industry is witnessing a shift towards synthetic and bio-based alternatives. These new formulations offer enhanced performance characteristics, such as higher thermal stability, better viscosity control, and reduced environmental impact. The choice of lubricant depends on various factors, including the type of machinery, operating conditions, and specific industry requirements.

Innovations in Lubrication Formulations

One of the most significant areas of innovation in industrial lubrication is the development of advanced lubricant formulations. These new products are designed to meet the increasing demands of modern machinery, which often operates under extreme conditions. Here are some of the key advancements:

- Synthetic Lubricants: Synthetic lubricants are engineered to provide superior performance compared to traditional mineral oils. They offer excellent thermal stability, oxidation resistance, and low-temperature fluidity, making them ideal for high-performance applications.

- Bio-based Lubricants: As industries strive for sustainability, bio-based lubricants have gained popularity. Derived from renewable resources, these lubricants are biodegradable and have a lower environmental impact, without compromising on performance.

- Nanotechnology-Enhanced Lubricants: The incorporation of nanoparticles into lubricants has led to significant improvements in reducing friction and wear. These nanoparticles create a protective layer on surfaces, enhancing the durability and efficiency of machinery.

Smart Lubrication Systems

In addition to advancements in lubricant formulations, the integration of smart technologies into lubrication systems is transforming industrial maintenance practices. Smart lubrication systems utilize sensors and IoT technology to monitor the condition of machinery and optimize lubrication processes. This approach offers several benefits:

- Real-Time Monitoring: Sensors embedded in machinery provide real-time data on temperature, pressure, and lubricant condition. This information allows for proactive maintenance, reducing the risk of equipment failure.

- Automated Lubrication: Smart systems can automatically adjust lubrication levels based on the operating conditions, ensuring optimal performance and reducing waste.

- Predictive Maintenance: By analyzing data trends, smart systems can predict when maintenance is needed, allowing for timely interventions and minimizing downtime.

Impact on Industry Sectors

The innovations in industrial lubrication technologies are having a profound impact across various sectors. Here are a few examples:

- Manufacturing: In manufacturing, efficient lubrication is critical for maintaining the precision and reliability of machinery. Advanced lubricants and smart systems help reduce maintenance costs and improve production efficiency.

- Automotive: The automotive industry benefits from high-performance lubricants that enhance engine efficiency and reduce emissions. Smart lubrication systems also contribute to the development of autonomous and electric vehicles.

- Energy: In the energy sector, particularly in wind and solar power, reliable lubrication is essential for the longevity of equipment. Innovations in this field support the growth of renewable energy by ensuring the durability of turbines and other machinery.

Challenges and Future Directions

Despite the advancements, the industrial lubrication sector faces several challenges. The development of new formulations requires significant research and testing to ensure compatibility with existing machinery. Additionally, the integration of smart systems demands investment in infrastructure and training for personnel.

Looking ahead, the focus will likely be on further enhancing the sustainability of lubricants and expanding the capabilities of smart systems. As industries continue to prioritize efficiency and environmental responsibility, the demand for innovative lubrication solutions will only grow.

In conclusion, the exploration of innovations in industrial lubrication technologies reveals a dynamic field that is essential for the advancement of modern industries. By embracing these innovations, companies can achieve greater efficiency, sustainability, and competitiveness in an ever-evolving market.