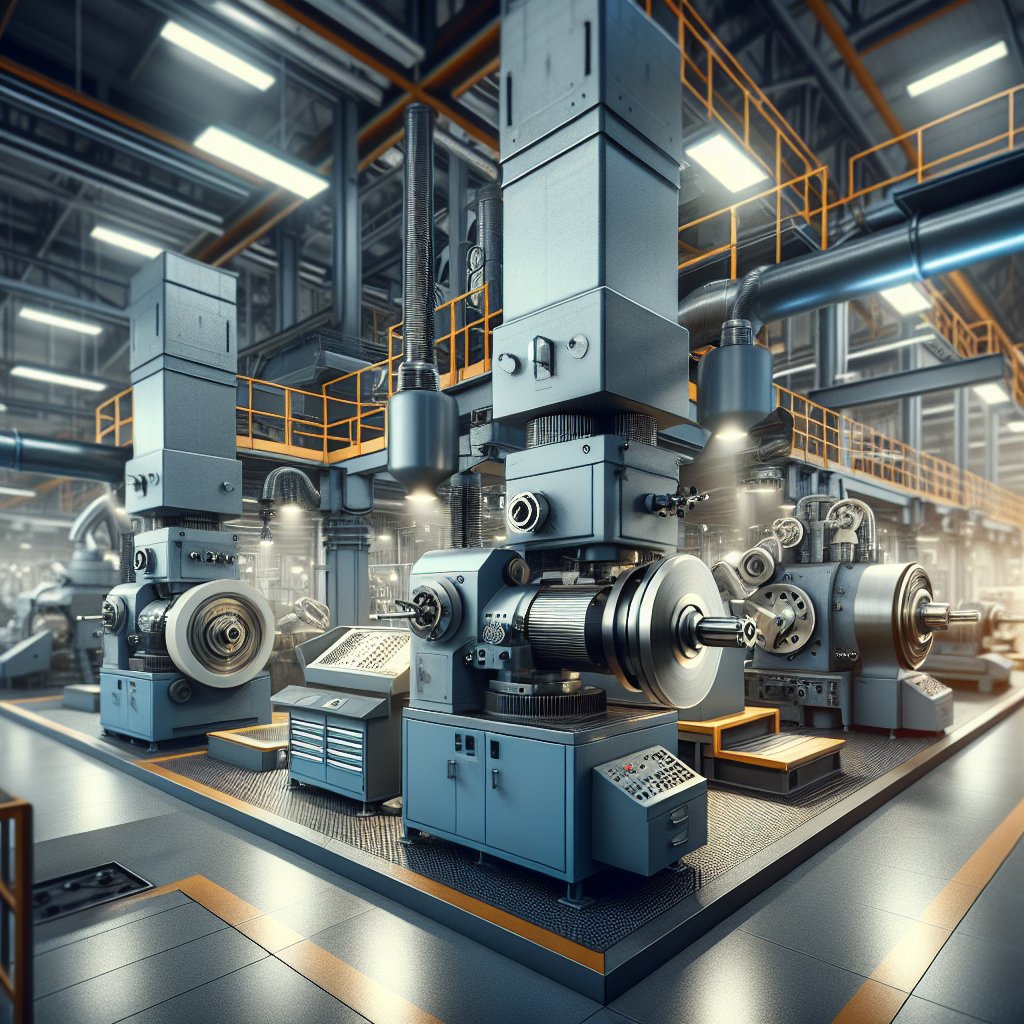

Industrial grinding machines play a crucial role in the manufacturing sector, providing the necessary precision and efficiency required for various applications. These machines are designed to remove material from a workpiece, achieving the desired shape and finish. In this article, we will explore the different types of industrial grinding machines, their applications, and the benefits they offer to various industries.

Types of Industrial Grinding Machines

Industrial grinding machines come in various types, each designed for specific applications and materials. Understanding the different types of grinding machines is essential for selecting the right equipment for a particular task. Below, we delve into some of the most common types of industrial grinding machines.

Surface Grinders

Surface grinders are one of the most common types of grinding machines used in the industry. They are designed to produce a smooth finish on flat surfaces. The workpiece is held in place on a table that moves back and forth under a rotating abrasive wheel. Surface grinders are ideal for creating precise and flat surfaces, making them essential in industries such as automotive, aerospace, and tool manufacturing.

- Applications: Surface grinders are used for finishing flat surfaces, creating precise dimensions, and achieving a high-quality finish.

- Benefits: They offer high precision, excellent surface finish, and the ability to work with a variety of materials.

Cylindrical Grinders

Cylindrical grinders are used to shape the outside of an object. The workpiece is rotated against a grinding wheel, which removes material to achieve the desired shape. These machines are commonly used for grinding cylindrical surfaces, such as shafts, rods, and other round components.

- Applications: Cylindrical grinders are used in the automotive, aerospace, and manufacturing industries for producing precision components.

- Benefits: They provide high accuracy, versatility, and the ability to work with both small and large workpieces.

Centerless Grinders

Centerless grinders are unique in that they do not require the workpiece to be held in place by a spindle or fixture. Instead, the workpiece is supported by a work rest blade and is rotated by a regulating wheel while being ground by a grinding wheel. This type of grinding machine is ideal for producing high-volume, precision parts with consistent quality.

- Applications: Centerless grinders are used in the production of small, cylindrical parts such as pins, bushings, and bearings.

- Benefits: They offer high throughput, consistent quality, and the ability to grind complex shapes.

Internal Grinders

Internal grinders are used to grind the internal surfaces of a workpiece. These machines are essential for creating precise holes and bores in components. The grinding wheel is inserted into the workpiece, and material is removed to achieve the desired dimensions and finish.

- Applications: Internal grinders are used in industries such as automotive, aerospace, and manufacturing for producing precision components with internal features.

- Benefits: They provide high precision, excellent surface finish, and the ability to work with complex internal geometries.

Applications and Benefits of Industrial Grinding Machines

Industrial grinding machines are used in a wide range of applications across various industries. Their ability to produce precise and high-quality finishes makes them indispensable in modern manufacturing. Below, we explore some of the key applications and benefits of industrial grinding machines.

Applications in the Automotive Industry

In the automotive industry, grinding machines are used to produce precision components such as engine parts, transmission components, and brake systems. The high precision and quality finish provided by grinding machines ensure that these components meet the stringent requirements of the industry.

- Benefits: Grinding machines help achieve tight tolerances, improve surface finish, and enhance the performance and longevity of automotive components.

Applications in the Aerospace Industry

The aerospace industry demands high precision and quality in its components, making grinding machines essential for producing parts such as turbine blades, landing gear components, and structural elements. The ability to work with a variety of materials, including exotic alloys, makes grinding machines ideal for aerospace applications.

- Benefits: Grinding machines provide the precision and quality required for aerospace components, ensuring safety and reliability in critical applications.

Applications in Tool Manufacturing

Tool manufacturing requires high precision and quality, making grinding machines essential for producing cutting tools, dies, and molds. The ability to achieve tight tolerances and excellent surface finish ensures that tools perform optimally and have a long service life.

- Benefits: Grinding machines help produce high-quality tools with precise dimensions, improving performance and reducing wear.

General Manufacturing Applications

In general manufacturing, grinding machines are used to produce a wide range of components, from small precision parts to large industrial components. The versatility and precision of grinding machines make them suitable for a variety of applications, including metalworking, woodworking, and plastics processing.

- Benefits: Grinding machines offer versatility, precision, and the ability to work with a wide range of materials, making them essential in modern manufacturing.

In conclusion, industrial grinding machines are vital tools in the manufacturing sector, offering precision, efficiency, and versatility for a wide range of applications. Understanding the different types of grinding machines and their applications can help industries select the right equipment for their specific needs, ensuring high-quality and efficient production processes.