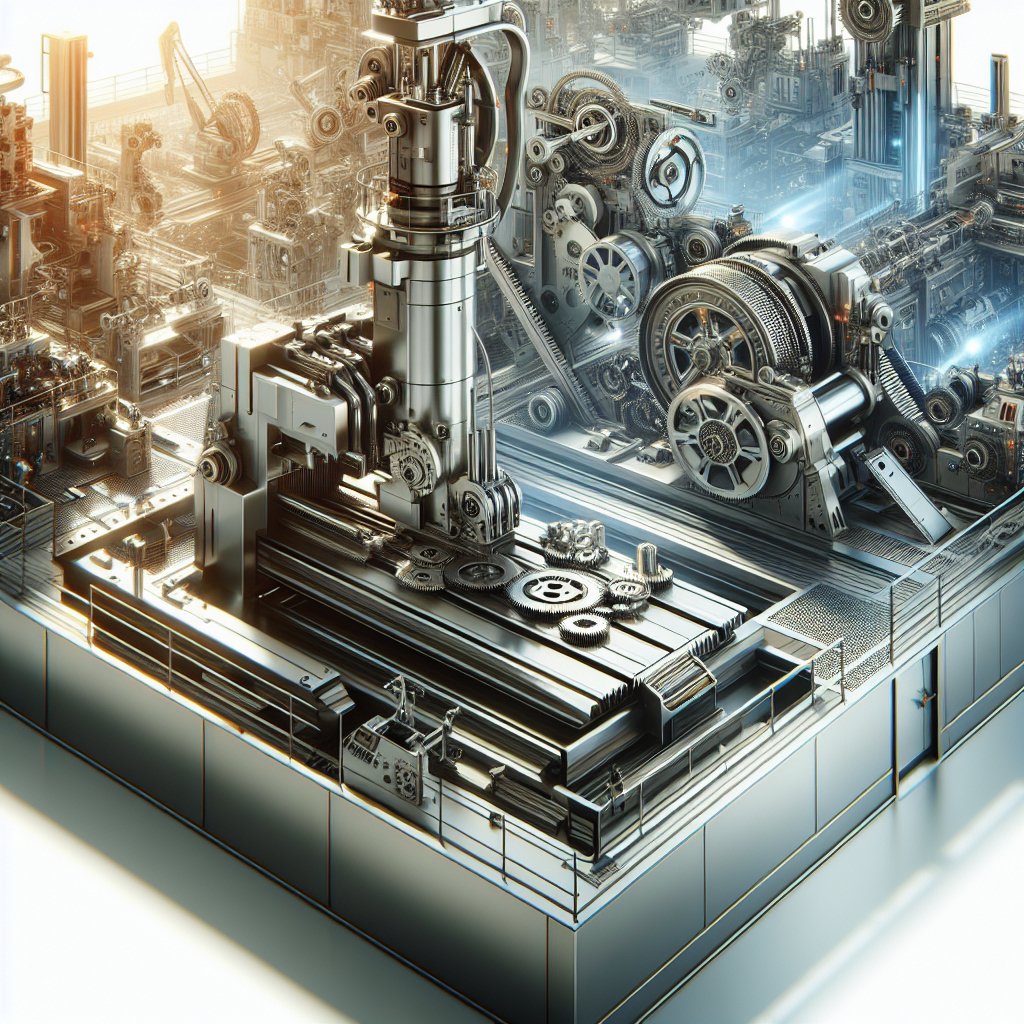

Advanced industrial cutting machines have revolutionized the manufacturing sector, offering precision, efficiency, and versatility across various industries. These machines are integral to processes ranging from automotive manufacturing to aerospace engineering, providing solutions that meet the demands of modern production. This article delves into the world of advanced industrial cutting machines, exploring their types, applications, and the technological advancements that continue to shape their development.

Types of Advanced Industrial Cutting Machines

Industrial cutting machines come in various forms, each designed to meet specific needs and applications. Understanding the different types of cutting machines is crucial for selecting the right equipment for a particular task. Below are some of the most common types of advanced industrial cutting machines:

Laser Cutting Machines

Laser cutting machines use a high-powered laser beam to cut materials with precision and speed. These machines are known for their ability to produce intricate designs and are widely used in industries such as automotive, aerospace, and electronics. The laser beam is directed through a series of mirrors and focused on the material, melting or vaporizing it to create clean cuts. Laser cutting is ideal for materials like metal, plastic, wood, and glass.

Waterjet Cutting Machines

Waterjet cutting machines utilize a high-pressure stream of water, often mixed with abrasive particles, to cut through materials. This method is highly versatile and can cut a wide range of materials, including metal, stone, ceramics, and composites. Waterjet cutting is particularly valued for its ability to cut without generating heat, which prevents material distortion and preserves the integrity of the material being cut.

Plasma Cutting Machines

Plasma cutting machines employ a high-velocity jet of ionized gas, or plasma, to cut through electrically conductive materials. These machines are commonly used for cutting steel, stainless steel, aluminum, and other metals. Plasma cutting is known for its speed and efficiency, making it a popular choice in industries that require rapid production and precise cuts.

Electric Discharge Machines (EDM)

Electric Discharge Machines, or EDM, use electrical discharges or sparks to erode material and create precise cuts. EDM is particularly useful for cutting hard materials and creating complex shapes that would be difficult to achieve with traditional cutting methods. This technology is widely used in the tool and die industry, as well as in the production of intricate components for aerospace and medical devices.

Applications of Advanced Industrial Cutting Machines

The versatility and precision of advanced industrial cutting machines make them indispensable across a wide range of industries. Here are some of the key applications of these machines:

Automotive Industry

In the automotive industry, cutting machines are used to manufacture various components, including body panels, engine parts, and interior elements. Laser and plasma cutting machines are particularly popular for their ability to produce high-quality cuts with minimal waste. The precision offered by these machines ensures that components fit together seamlessly, contributing to the overall performance and safety of vehicles.

Aerospace Industry

The aerospace industry demands high precision and reliability, making advanced cutting machines essential for manufacturing aircraft components. Waterjet and EDM machines are often used to cut materials like titanium and composites, which are commonly used in aircraft construction. These machines ensure that parts meet strict tolerances and quality standards, which are critical for the safety and performance of aircraft.

Electronics Industry

In the electronics industry, cutting machines are used to produce circuit boards, enclosures, and other components. Laser cutting machines are particularly suited for this industry due to their ability to create intricate designs and precise cuts. The precision of laser cutting ensures that electronic components fit together perfectly, which is essential for the functionality and reliability of electronic devices.

Construction and Architecture

Advanced cutting machines are also used in the construction and architecture industries to create custom designs and components. Waterjet and laser cutting machines are often employed to cut materials like stone, glass, and metal for use in building facades, interior design elements, and structural components. These machines enable architects and builders to achieve complex designs and high-quality finishes that enhance the aesthetic and functional aspects of buildings.

Technological Advancements in Cutting Machines

The field of industrial cutting machines is continuously evolving, with new technologies and innovations enhancing their capabilities. Some of the recent advancements in cutting machine technology include:

Automation and CNC Integration

Automation and Computer Numerical Control (CNC) integration have significantly improved the efficiency and precision of cutting machines. CNC systems allow for the automation of cutting processes, reducing the need for manual intervention and minimizing the risk of human error. This technology enables manufacturers to produce complex parts with high accuracy and repeatability, increasing productivity and reducing production costs.

Advanced Materials and Cutting Techniques

As new materials are developed, cutting machines are being adapted to handle these materials with precision and efficiency. For example, advancements in laser technology have enabled the cutting of materials like carbon fiber and advanced composites, which are increasingly used in industries such as aerospace and automotive. Additionally, new cutting techniques, such as hybrid cutting methods that combine laser and waterjet technologies, are being developed to enhance cutting capabilities and expand the range of materials that can be processed.

Improved Software and Control Systems

Modern cutting machines are equipped with advanced software and control systems that enhance their performance and usability. These systems provide operators with greater control over cutting parameters, allowing for the optimization of cutting processes and the achievement of high-quality results. Improved software also facilitates the integration of cutting machines into larger manufacturing systems, enabling seamless communication and coordination between different stages of production.

Conclusion

Advanced industrial cutting machines play a crucial role in modern manufacturing, offering precision, efficiency, and versatility across a wide range of applications. From automotive and aerospace to electronics and construction, these machines are essential for producing high-quality components that meet the demands of today’s industries. As technology continues to advance, cutting machines will become even more capable, enabling manufacturers to push the boundaries of what is possible and drive innovation in their respective fields.