Laser cutting technology has revolutionized the industrial sector, offering precision, efficiency, and versatility that traditional cutting methods cannot match. As industries continue to evolve, the demand for advanced laser cutting solutions has grown, leading to significant innovations in this field. This article explores the latest advancements in laser cutting technology and their implications for industrial applications.

Understanding Laser Cutting Technology

Laser cutting is a technology that uses a laser to cut materials, and it is typically used for industrial manufacturing applications. The process involves directing the output of a high-power laser through optics, which is then used to cut materials for various applications. The laser beam is focused on the material, causing it to melt, burn, vaporize, or be blown away by a jet of gas, leaving an edge with a high-quality surface finish.

There are several types of lasers used in cutting, including CO2 lasers, fiber lasers, and Nd:YAG lasers. Each type has its own advantages and is suited for different materials and applications. CO2 lasers are commonly used for cutting non-metal materials, while fiber lasers are preferred for cutting metals due to their high power and efficiency.

CO2 Lasers

CO2 lasers are gas lasers that use a gas mixture as the lasing medium. They are highly efficient and capable of cutting a wide range of materials, including wood, acrylic, and plastics. CO2 lasers are known for their ability to produce smooth and precise cuts, making them ideal for applications that require high-quality finishes.

Fiber Lasers

Fiber lasers are solid-state lasers that use optical fibers doped with rare-earth elements as the lasing medium. They are known for their high power output and efficiency, making them suitable for cutting metals such as steel, aluminum, and copper. Fiber lasers offer faster cutting speeds and lower operating costs compared to CO2 lasers, making them a popular choice in the metalworking industry.

Recent Advancements in Laser Cutting Technology

Recent years have seen significant advancements in laser cutting technology, driven by the need for greater precision, speed, and efficiency in industrial applications. These advancements have expanded the capabilities of laser cutting systems, allowing them to handle more complex tasks and a wider range of materials.

High-Power Lasers

One of the most notable advancements in laser cutting technology is the development of high-power lasers. These lasers offer increased cutting speeds and the ability to cut thicker materials, making them ideal for heavy-duty industrial applications. High-power lasers also provide improved edge quality and reduced heat-affected zones, resulting in better overall cut quality.

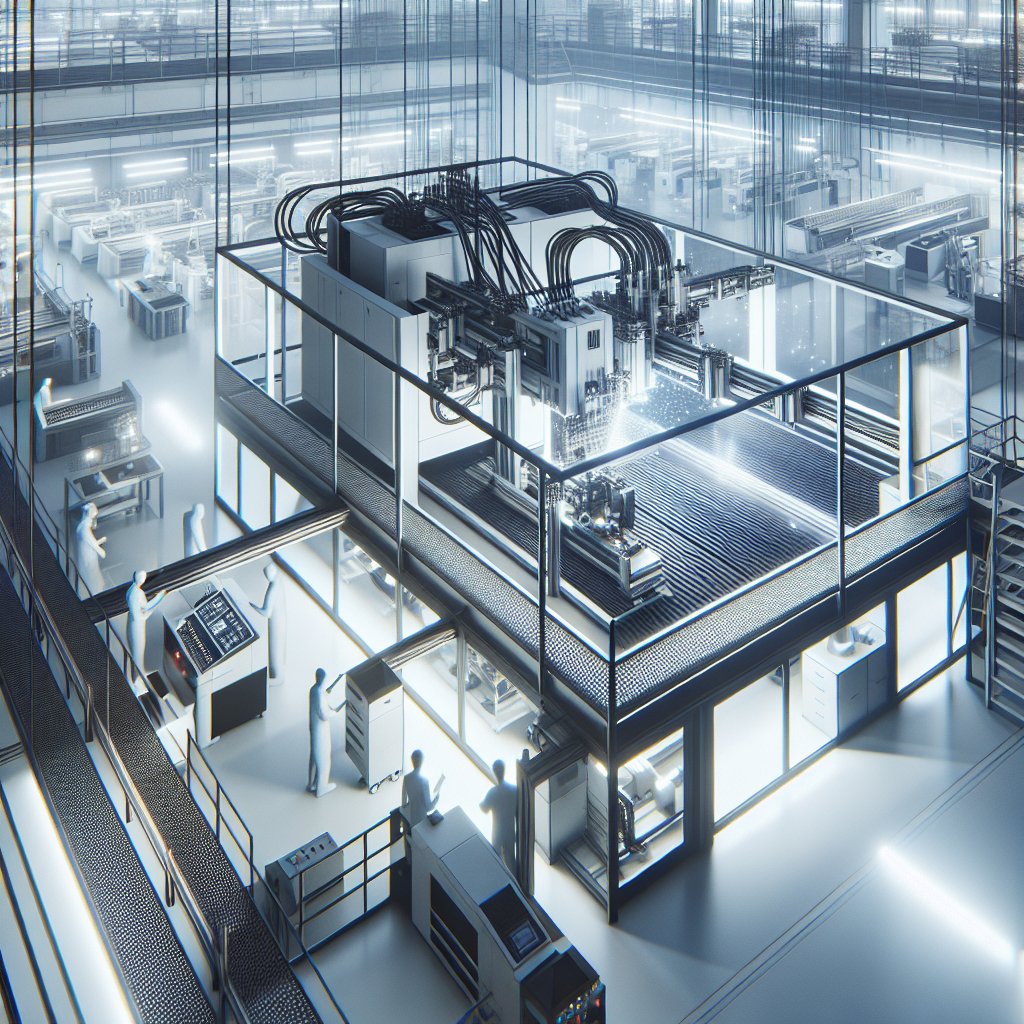

Automation and Integration

Automation has become a key focus in the development of laser cutting technology. Modern laser cutting systems are increasingly being integrated with automated material handling systems, allowing for continuous operation and reduced downtime. This integration enhances productivity and efficiency, enabling manufacturers to meet the demands of high-volume production.

Advanced Software and Control Systems

Advancements in software and control systems have also played a crucial role in the evolution of laser cutting technology. Modern laser cutting machines are equipped with sophisticated software that allows for precise control of the cutting process. This software enables features such as real-time monitoring, adaptive control, and predictive maintenance, ensuring optimal performance and reducing the risk of errors.

Implications for Industrial Applications

The advancements in laser cutting technology have significant implications for various industrial applications. Industries such as automotive, aerospace, electronics, and construction are benefiting from the enhanced capabilities of modern laser cutting systems.

Automotive Industry

In the automotive industry, laser cutting technology is used for cutting complex shapes and intricate designs in metal components. The precision and speed of laser cutting allow for the production of high-quality parts with minimal waste, contributing to cost savings and improved efficiency in manufacturing processes.

Aerospace Industry

The aerospace industry requires components with high precision and reliability. Laser cutting technology meets these requirements by providing accurate cuts and smooth finishes, essential for the production of critical aerospace components. The ability to cut lightweight materials such as titanium and composites also makes laser cutting an ideal choice for aerospace applications.

Electronics Industry

In the electronics industry, laser cutting is used for cutting and shaping circuit boards, as well as for engraving and marking components. The precision of laser cutting ensures that delicate electronic components are not damaged during the manufacturing process, resulting in high-quality products.

Construction Industry

The construction industry benefits from laser cutting technology through the production of custom metal components and architectural elements. Laser cutting allows for the creation of intricate designs and patterns, enabling architects and builders to achieve unique and aesthetically pleasing structures.

Conclusion

Advancements in laser cutting technology have transformed the industrial landscape, offering enhanced precision, speed, and efficiency. As industries continue to demand more complex and high-quality products, laser cutting technology will play a crucial role in meeting these needs. The ongoing development of high-power lasers, automation, and advanced software will further expand the capabilities of laser cutting systems, ensuring their continued relevance in the industrial sector.