Programmable Logic Controllers (PLCs) have become a cornerstone in the automation of industrial systems, providing a reliable and efficient means of controlling machinery and processes. These devices are integral to modern manufacturing and production environments, offering flexibility, precision, and scalability. This article delves into the intricacies of PLCs, exploring their architecture, functionality, and the pivotal role they play in industrial automation.

Introduction to Programmable Logic Controllers

PLCs are specialized computers used for the control and automation of industrial processes. They are designed to withstand harsh industrial environments and provide real-time control over machinery and processes. Unlike general-purpose computers, PLCs are built to handle multiple inputs and outputs, making them ideal for complex control tasks in manufacturing, assembly lines, and other industrial applications.

The development of PLCs dates back to the late 1960s when the automotive industry sought a more efficient way to control assembly lines. Traditional relay-based control systems were cumbersome and inflexible, prompting the need for a programmable solution. The introduction of PLCs revolutionized industrial automation, offering a more streamlined and adaptable approach to process control.

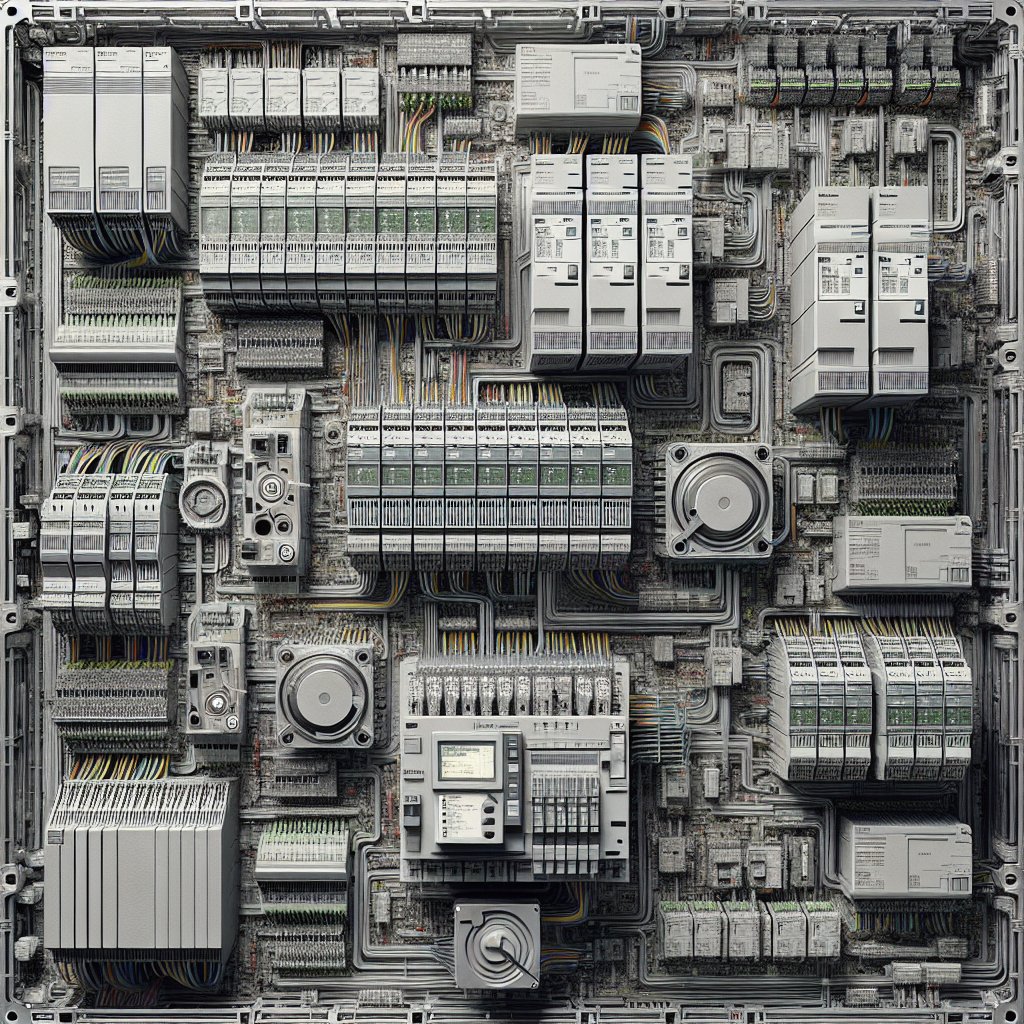

Architecture and Components of PLCs

At the core of a PLC is its architecture, which consists of several key components that work together to execute control tasks. Understanding these components is essential for grasping how PLCs function and their application in industrial systems.

Central Processing Unit (CPU)

The CPU is the brain of the PLC, responsible for executing control instructions and managing data flow. It processes input signals, executes the control program, and sends output signals to actuators and other devices. The CPU’s processing power and speed are critical factors in determining the PLC’s performance and capability.

Input/Output (I/O) Modules

I/O modules are the interface between the PLC and the external environment. Input modules receive signals from sensors and other input devices, while output modules send control signals to actuators, motors, and other output devices. The number and type of I/O modules can be customized to suit specific application requirements, providing flexibility in system design.

Power Supply

The power supply unit provides the necessary electrical power to the PLC and its components. It ensures stable and reliable operation, even in environments with fluctuating power conditions. The power supply is designed to meet the specific voltage and current requirements of the PLC system.

Programming Device

Programming devices are used to create, edit, and upload control programs to the PLC. These devices can range from dedicated handheld programmers to sophisticated software tools running on personal computers. The programming language used for PLCs is typically ladder logic, although other languages such as structured text and function block diagrams are also common.

Functionality and Operation of PLCs

PLCs operate by continuously scanning their inputs, executing the control program, and updating their outputs. This cycle, known as the scan cycle, is repeated continuously to ensure real-time control of industrial processes. The speed and efficiency of the scan cycle are crucial for maintaining precise control and minimizing response times.

Input Processing

During the input processing phase, the PLC reads the status of all input devices connected to its input modules. This data is then stored in the PLC’s memory, where it can be accessed by the control program. Input devices can include sensors, switches, and other devices that provide information about the process being controlled.

Program Execution

Once the input data is collected, the PLC executes the control program stored in its memory. The program consists of a series of instructions that define how the PLC should respond to different input conditions. These instructions are typically written in ladder logic, a graphical programming language that resembles electrical relay logic diagrams.

Output Processing

After executing the control program, the PLC updates the status of its output devices based on the program’s instructions. This involves sending control signals to actuators, motors, and other devices that perform actions in the industrial process. The output processing phase ensures that the PLC’s control actions are implemented in real-time.

Applications of PLCs in Industrial Systems

PLCs are used in a wide range of industrial applications, from simple machine control to complex process automation. Their versatility and reliability make them an essential component in many industries, including manufacturing, automotive, food and beverage, and energy.

Manufacturing and Assembly Lines

In manufacturing, PLCs are used to control assembly lines, coordinate robotic arms, and manage conveyor systems. They ensure precise timing and synchronization of operations, improving efficiency and reducing downtime. PLCs also enable quick reconfiguration of production lines to accommodate different products and processes.

Process Control

PLCs play a critical role in process control applications, such as chemical processing, water treatment, and oil and gas production. They monitor and regulate variables such as temperature, pressure, and flow rate, ensuring optimal process conditions and product quality. PLCs can also integrate with other control systems, such as Distributed Control Systems (DCS), for comprehensive process management.

Building Automation

In building automation, PLCs are used to control HVAC systems, lighting, and security systems. They provide centralized control and monitoring, improving energy efficiency and occupant comfort. PLCs can also be integrated with building management systems (BMS) for enhanced functionality and data analysis.

Advantages and Challenges of Using PLCs

PLCs offer numerous advantages in industrial automation, but they also present certain challenges that must be addressed to ensure successful implementation and operation.

Advantages

- Reliability: PLCs are designed to operate in harsh industrial environments, providing reliable and consistent performance.

- Flexibility: PLCs can be easily reprogrammed and reconfigured to accommodate changes in production processes and requirements.

- Scalability: PLC systems can be expanded by adding additional I/O modules and devices, allowing for growth and adaptation.

- Real-time Control: PLCs provide real-time monitoring and control, ensuring timely responses to process changes and disturbances.

Challenges

- Complexity: Designing and programming PLC systems can be complex, requiring specialized knowledge and expertise.

- Cost: The initial cost of PLC hardware and software can be significant, particularly for large-scale systems.

- Maintenance: Regular maintenance and updates are necessary to ensure optimal performance and prevent system failures.

- Integration: Integrating PLCs with other control systems and technologies can be challenging, requiring careful planning and coordination.

Future Trends in PLC Technology

The field of PLC technology is continually evolving, driven by advancements in computing, communication, and automation technologies. Several trends are shaping the future of PLCs, offering new opportunities and challenges for industrial automation.

Internet of Things (IoT) Integration

The integration of IoT technologies with PLCs is enabling more connected and intelligent industrial systems. IoT-enabled PLCs can collect and analyze data from a wide range of sensors and devices, providing valuable insights into process performance and efficiency. This connectivity also facilitates remote monitoring and control, enhancing flexibility and responsiveness.

Edge Computing

Edge computing is becoming increasingly important in industrial automation, allowing data processing and analysis to occur closer to the source of data generation. PLCs with edge computing capabilities can perform real-time data analysis and decision-making, reducing latency and improving system performance. This trend is particularly relevant for applications requiring fast response times and high data volumes.

Advanced Programming Languages

While ladder logic remains the dominant programming language for PLCs, there is a growing interest in using more advanced languages, such as structured text and function block diagrams. These languages offer greater flexibility and expressiveness, enabling the development of more complex and sophisticated control programs. The adoption of these languages is expected to increase as PLC technology continues to evolve.

Conclusion

Programmable Logic Controllers are a vital component of modern industrial systems, providing the control and automation necessary for efficient and reliable operation. As technology continues to advance, PLCs are becoming more powerful, connected, and versatile, opening new possibilities for industrial automation. Understanding the architecture, functionality, and applications of PLCs is essential for leveraging their full potential and addressing the challenges of industrial automation in the 21st century.