Heavy machinery forms the backbone of construction, manufacturing, and logistics operations around the globe. From towering cranes to robust excavators, these mechanical giants must undergo a series of rigorous evaluations to guarantee their **durability**, **safety**, and performance under demanding conditions. This article explores the methodologies and best practices that engineers and technicians employ when testing cranes and other machines at work, focusing on strength and stability assessments, preventive protocols, and real-world applications.

Testing Principles for Heavy Machinery

Before any piece of equipment can be cleared for operation, it must satisfy a comprehensive set of criteria that define its structural and operational integrity. The core objectives of these tests are:

- Verification of design specifications against real-world demands

- Confirmation of material performance under varied **load** conditions

- Assessment of system responses to dynamic and static forces

- Evaluation of safety margins beyond expected work parameters

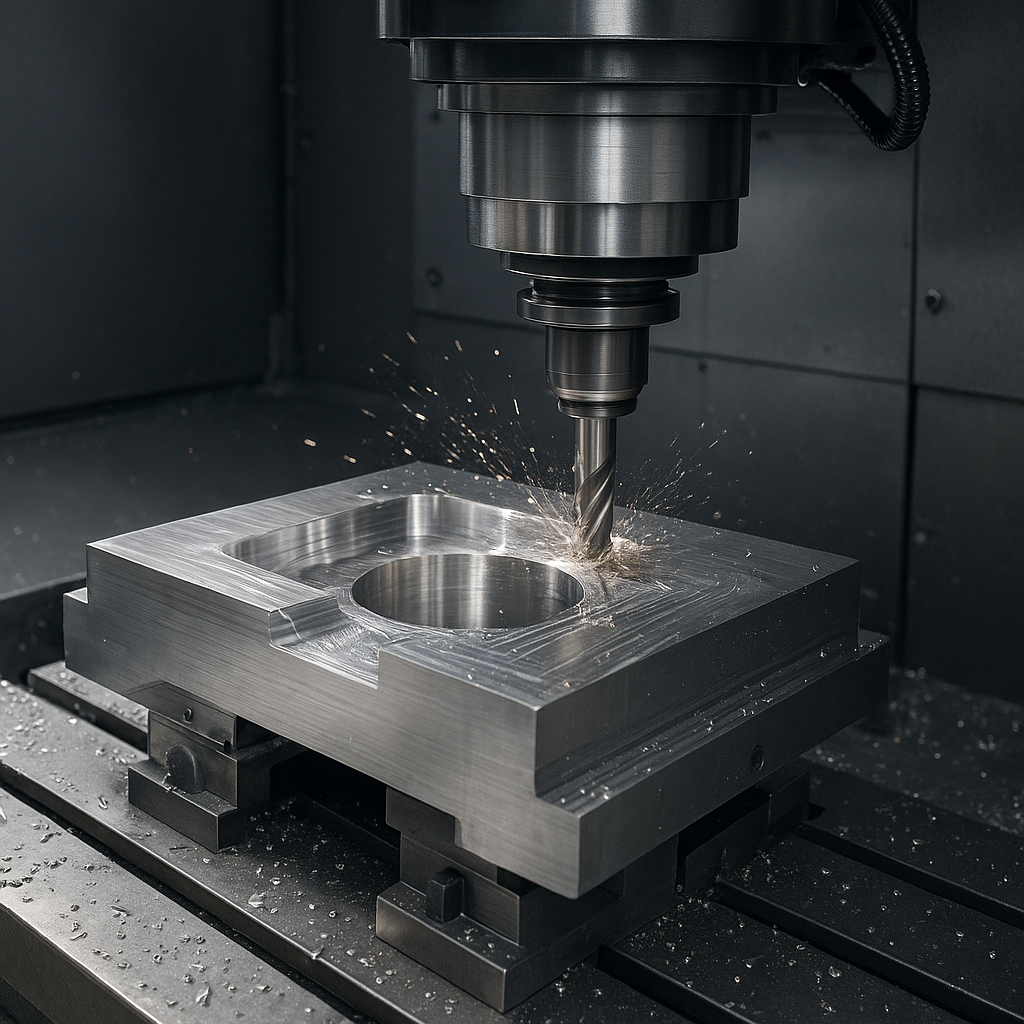

Engineers rely on a mixture of analytical models, physical prototypes, and field trials. Computational tools, such as finite element analysis (FEA), allow for virtual stress mapping, but physical bench tests provide the definitive proof that each component meets or exceeds prescribed limits. Combining these approaches ensures a holistic understanding of potential failure points.

Load Testing and Stress Analysis

Load testing is central to proving that a crane or similar apparatus can lift, swing, and position objects without risking structural compromise. The process typically involves:

- Applying incremental weights up to 125–150% of the crane’s rated capacity

- Measuring deflection of booms, cables, and support structures

- Monitoring stresses in welds, joints, and pivot points

- Recording strain levels with high-precision sensors

During static load tests, engineers incrementally increase the weight while the machine remains stationary. They watch for unexpected deformations or permanent bends and note any material yielding. In dynamic load tests, the crane moves through its full range of motion while carrying weight, simulating real-life operations.

Analyzing Stress Distribution

Strain gauges and digital transducers play a key role in capturing the distribution of **stress** throughout the structure. By plotting stress contours, technicians can identify **fatigue** hotspots and weak areas that might require reinforcement. These insights guide design improvements and maintenance strategies, preventing potential failures in the field.

Stability and Balance Assessment

Ensuring that a crane remains upright and stable under both static and dynamic conditions is non-negotiable for operational safety. Stability tests cover:

- Tipping load analysis at varying boom angles

- Outrigger footprint evaluation on different ground surfaces

- Center of gravity tracking during load maneuvers

- Wind load impact simulations

Technicians simulate adverse scenarios such as sudden stops, prolonged sway, or side-loading forces. They measure lateral and longitudinal tilt angles and confirm that safety systems intervene before reaching critical thresholds. Automatic locking valves, anti-two-block devices, and load-moment indicators are all verified during this stage.

Outrigger and Baseplate Testing

An essential element of stability checks involves the outrigger system. Each pad must distribute weight evenly, and hydraulics must maintain extended pressure over time. Engineers perform extended-duration tests to catch any gradual pressure loss or seal failures, thereby ensuring that the machine remains secure under continuous operation.

Preventive Maintenance and Inspection Protocols

Even the most robust cranes require ongoing **inspection** and upkeep. Preventive maintenance programs rely on scheduled checks and advanced diagnostic tools to catch issues early. Key activities include:

- Visual inspections for cracks, corrosion, or worn components

- Non-destructive testing such as ultrasonic or magnetic particle scans

- Hydraulic fluid analysis and filter replacements

- Routine **calibration** of sensors and control systems

Modern condition-monitoring solutions incorporate vibration analysis, thermal imaging, and oil debris sensors. These technologies alert maintenance teams to developing problems, reducing downtime and extending service life. Regular lubrication of pins, bearings, and bushings prevents excess **fatigue**, while torque checks on fasteners preserve structural integrity.

Operator Training and Safety Culture

Machines are only as safe and efficient as the people who operate them. Comprehensive training programs ensure that operators understand:

- Load charts and capacity limits

- Proper set-up procedures on varied terrain

- Emergency shutdown and rescue protocols

- Daily pre-operation checklists

Operator competence enhances the effectiveness of built-in safety features. Realistic simulations and hands-on practice under supervision cultivate a proactive safety culture. Continuous education reinforces best practices and updates crews on the latest regulations and technological advancements.

Advances in Technology and Future Trends

The rise of digital twins, real-time analytics, and remote monitoring is reshaping how machines are tested and maintained. Virtual replicas of cranes enable engineers to run stress tests under a vast array of conditions without risking physical assets. Artificial intelligence algorithms analyze operational data, predicting failures before they occur.

- Integration of IoT sensors for live performance data

- Predictive maintenance using machine learning models

- Augmented reality (AR) for guided inspections

- Autonomous self-leveling and self-diagnostic systems

These developments promise higher uptime, lower operating costs, and enhanced **safety** margins. They also support more sustainable operations by optimizing energy use and reducing material waste.