Computer Numerical Control machines have revolutionized the way industries produce components, turning complex designs into tangible products with unmatched accuracy. From aerospace parts to medical implants, these systems have become indispensable in modern manufacturing. This article explores how advanced machinery operates on the factory floor and examines related themes shaping the future of production.

Precision Engineering in Action

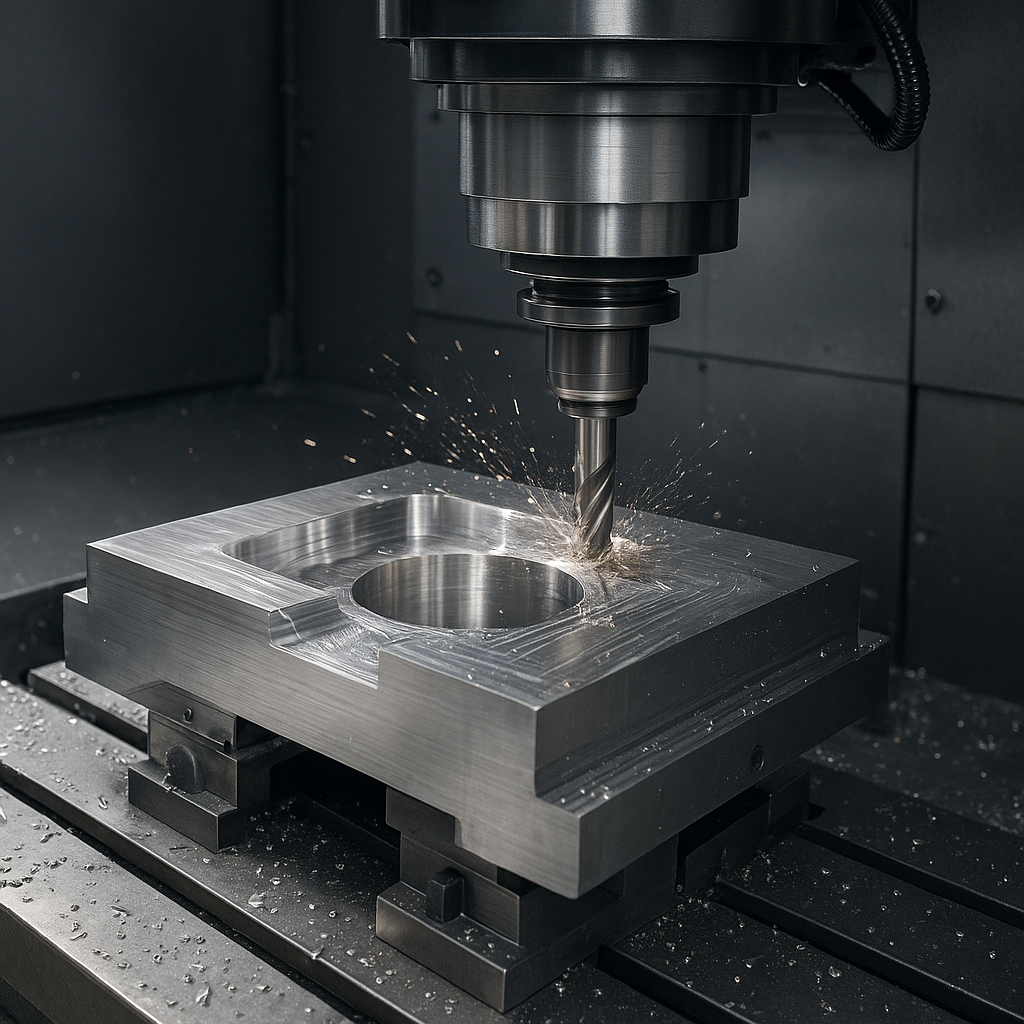

The heart of every CNC machine is its ability to execute designs with precision down to fractions of a millimeter. Whether milling, turning, or cutting, these systems rely on pre-programmed instructions to guide high-speed spindles and tool heads along exact paths. The result is consistent and repeatable parts that meet tight tolerances, drastically reducing human error.

Material Versatility

One of the standout features of modern machining is the ability to work with a diverse range of materials:

- Metals such as aluminum, steel, titanium, and brass

- Engineering plastics like Delrin, PTFE, and ABS

- Composite materials reinforced with carbon or glass fibers

- Exotic alloys used in aerospace and medical applications

By adjusting parameters like feed rate, spindle speed, and cooling methods, operators can tailor the machining process to each material’s unique properties. This versatility empowers industries to innovate and respond to evolving design requirements.

Automation Driving Efficiency

Automation has become the cornerstone of the “lights-out” manufacturing concept, where machines run unattended for extended periods. With integrated robotics, tool changers, and advanced software, CNC cells can:

- Load and unload workpieces automatically

- Monitor tool wear and replace cutting tools on demand

- Perform in-process quality checks using laser probes and cameras

- Adjust machining parameters in real-time for optimal performance

These automated workflows boost efficiency by minimizing downtime and maximizing machine utilization. Operators shift from manual tasks to higher-value roles, focusing on programming, maintenance, and process optimization.

Innovation and Future Trends

Emerging technologies are pushing the boundaries of what CNC machines can achieve. Additive manufacturing heads are being integrated alongside subtractive tools for hybrid cells, allowing for the growth and finishing of complex geometries in a single setup. Key trends include:

- Smart factories leveraging the Industrial Internet of Things (IIoT) to collect and analyze performance data

- Artificial intelligence algorithms that predict tool failure before it occurs

- Augmented reality interfaces assisting technicians with maintenance and programming tasks

- Eco-friendly machining practices that reduce energy consumption and waste

By embracing these innovations, manufacturers can achieve higher throughput, improved part quality, and greater adaptability in the face of market demands.

Workforce Transformation and Skills Development

The rise of advanced machinery has shifted the skillset required on the shop floor. Traditional machinists are evolving into digital operators who must master:

- CNC programming languages like G-code and CAM software platforms

- Data analysis tools to monitor and optimize machine performance

- Maintenance procedures for both mechanical components and electronic systems

- Collaborative problem-solving in cross-functional engineering teams

Training programs now emphasize a blend of hands-on experience and digital literacy. Apprenticeships and vocational schools are partnering with machine tool builders to ensure a steady pipeline of skilled workers adept at managing technology-driven environments.

Quality Assurance and Regulatory Compliance

In industries like automotive, medical, and aerospace, stringent regulations demand rigorous quality control. CNC machines contribute to compliance by offering:

- Traceable tool paths and machine logs for complete process documentation

- Automated inspection routines that measure critical dimensions in real time

- Surface finish controls to meet certification standards

- Material traceability from raw stock to finished component

Such capabilities help manufacturers deliver products that adhere to safety and performance requirements while reducing the risk of costly recalls or certification delays. The integration of traceable digital records also supports ongoing audits and continuous improvement initiatives.

Sustainability in Machining

As global attention turns toward environmental responsibility, CNC operations are adopting greener practices. Key approaches include:

- Using biodegradable and water-soluble coolants to minimize hazardous waste

- Optimizing cutting strategies to reduce material scrap and energy consumption

- Implementing energy-efficient drives and motors to lower power usage

- Recycling chips and swarf through specialized processing systems

These measures not only align with corporate sustainability goals but also offer cost savings over the long term. By championing sustainability, manufacturers can appeal to environmentally conscious customers and comply with tightening regulations.

Conclusion: Machines at the Forefront of Progress

The synergy of automation, advanced manufacturing techniques, and continuous innovation positions CNC machines as key drivers of industrial growth. From improving part accuracy to enabling smart, connected operations, these systems are shaping a more efficient, adaptable, and responsible production landscape. As technology advances, the partnership between skilled operators and intelligent machines will unlock new possibilities, ensuring that the modern world continues to evolve with ever-greater capabilities.