Industrial robotics has been a cornerstone of modern manufacturing, driving efficiency and innovation across various sectors. As we look to the future, the landscape of industrial robotics is poised for significant transformation, influenced by emerging technologies and evolving market demands. This article delves into the key trends shaping the future of industrial robotics and the challenges that lie ahead for the industry.

Emerging Trends in Industrial Robotics

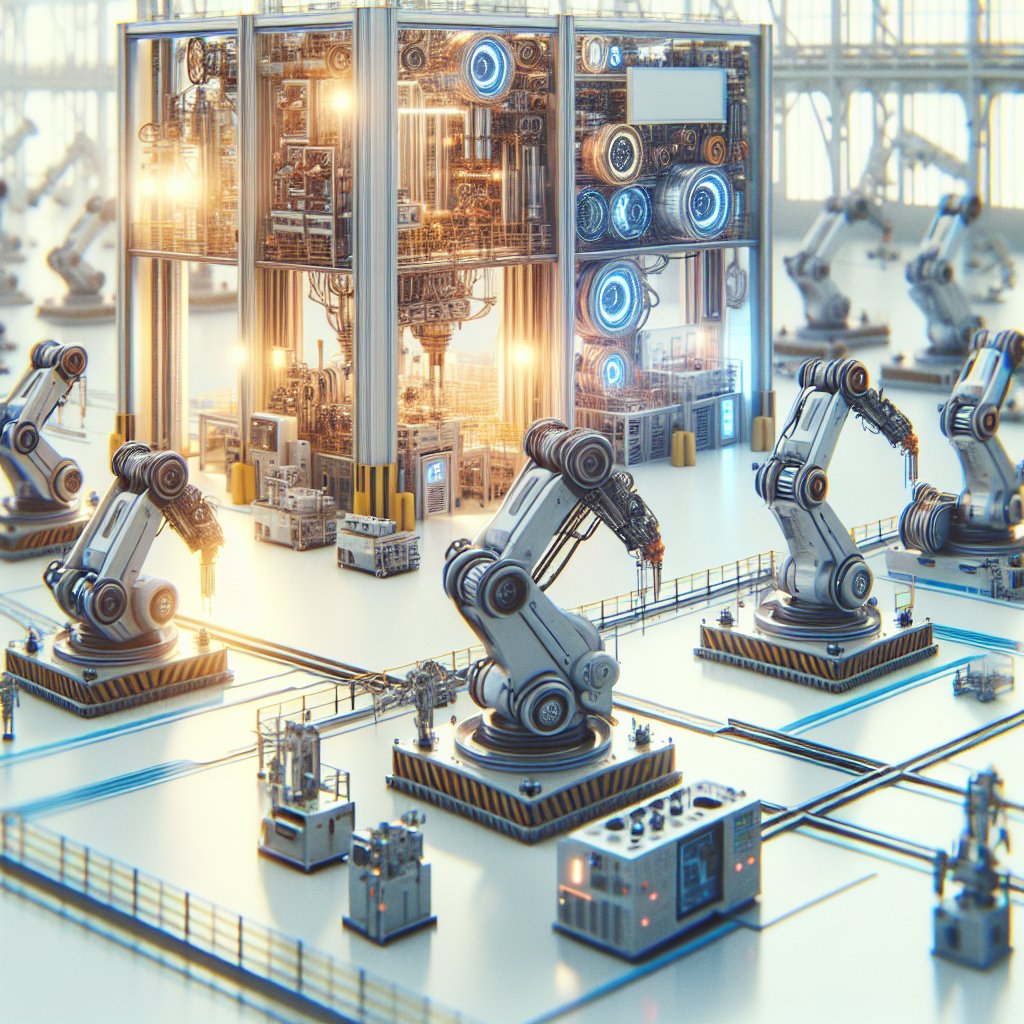

The industrial robotics sector is undergoing a rapid evolution, driven by advancements in technology and changing industrial needs. One of the most significant trends is the integration of artificial intelligence (AI) and machine learning into robotic systems. These technologies enable robots to perform complex tasks with greater precision and adaptability, making them indispensable in industries such as automotive, electronics, and logistics.

Another trend is the rise of collaborative robots, or cobots, designed to work alongside humans in a shared workspace. Unlike traditional industrial robots, which are often isolated for safety reasons, cobots are equipped with advanced sensors and safety features that allow them to operate safely in close proximity to human workers. This collaboration enhances productivity and allows for more flexible manufacturing processes.

Additionally, the adoption of the Internet of Things (IoT) in industrial robotics is transforming how robots are monitored and controlled. IoT-enabled robots can communicate with other machines and systems, providing real-time data and insights that improve operational efficiency and predictive maintenance. This connectivity is crucial for the development of smart factories and Industry 4.0 initiatives.

Challenges Facing the Industrial Robotics Industry

Despite the promising trends, the industrial robotics industry faces several challenges that could impact its growth and adoption. One of the primary challenges is the high cost of robotic systems, which can be prohibitive for small and medium-sized enterprises (SMEs). While the long-term benefits of automation are clear, the initial investment required for robotic systems can be a significant barrier for many companies.

Another challenge is the need for skilled labor to design, program, and maintain robotic systems. As robots become more sophisticated, the demand for workers with expertise in robotics, AI, and data analytics is increasing. However, there is a shortage of such skilled professionals, which could hinder the deployment and optimization of robotic systems in various industries.

Furthermore, the integration of robots into existing workflows and systems can be complex and time-consuming. Companies must ensure that their robotic systems are compatible with their current infrastructure and that they can seamlessly integrate with other technologies. This requires careful planning and coordination, which can be a daunting task for many organizations.

Finally, there are concerns about the ethical and social implications of increased automation. As robots take on more tasks traditionally performed by humans, there is a risk of job displacement and economic inequality. Addressing these concerns requires a balanced approach that considers both the benefits of automation and the need to support workers through retraining and reskilling initiatives.

Conclusion

The future of industrial robotics is bright, with numerous opportunities for innovation and growth. However, the industry must navigate several challenges to fully realize its potential. By embracing emerging technologies, addressing cost and skill barriers, and considering the ethical implications of automation, the industrial robotics sector can continue to drive progress and transformation in the manufacturing landscape.