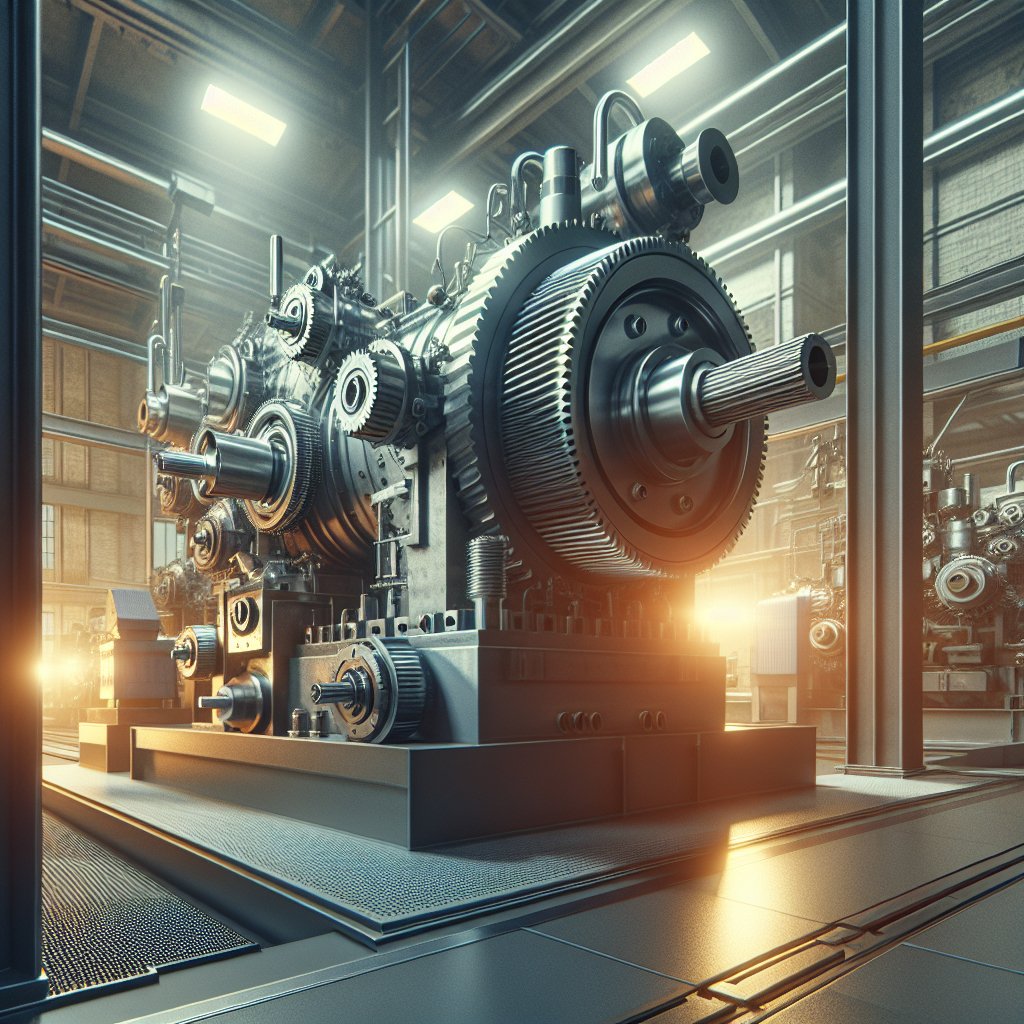

Industrial gearboxes are critical components in a wide range of machinery and equipment, playing a vital role in the transmission of power and motion. Ensuring their longevity and optimal performance is essential for maintaining operational efficiency and reducing downtime. This article explores the best practices for extending the life of industrial gearboxes, focusing on maintenance strategies, lubrication techniques, and monitoring systems.

Understanding the Importance of Regular Maintenance

Regular maintenance is the cornerstone of extending the life of industrial gearboxes. By implementing a structured maintenance schedule, operators can identify potential issues before they escalate into major problems. This proactive approach not only enhances the lifespan of the gearbox but also improves the overall reliability of the machinery.

Scheduled Inspections

Scheduled inspections are crucial for detecting early signs of wear and tear. During these inspections, technicians should check for unusual noises, vibrations, and temperature fluctuations, which can indicate underlying issues. Additionally, examining the gearbox for leaks and ensuring that all bolts and connections are secure can prevent further damage.

Cleaning and Debris Removal

Keeping the gearbox clean and free from debris is another essential aspect of maintenance. Accumulated dirt and grime can lead to overheating and increased friction, which can accelerate wear. Regular cleaning helps maintain optimal operating conditions and prevents contaminants from entering the gearbox.

Optimizing Lubrication Practices

Lubrication is a critical factor in the performance and longevity of industrial gearboxes. Proper lubrication reduces friction, minimizes wear, and helps dissipate heat. However, using the wrong type of lubricant or failing to maintain appropriate levels can lead to significant damage.

Choosing the Right Lubricant

Selecting the appropriate lubricant for a specific gearbox is essential. Factors such as operating temperature, load, and speed should be considered when choosing a lubricant. Manufacturers often provide recommendations for suitable lubricants, and adhering to these guidelines can prevent premature failure.

Regular Lubricant Analysis

Regular analysis of the lubricant can provide valuable insights into the condition of the gearbox. By monitoring the lubricant’s viscosity, contamination levels, and chemical composition, operators can detect potential issues early. This information allows for timely interventions, such as changing the lubricant or addressing contamination sources.

Implementing Advanced Monitoring Systems

Advanced monitoring systems have become increasingly popular in extending the life of industrial gearboxes. These systems provide real-time data on the gearbox’s performance, allowing for more informed maintenance decisions.

Vibration Analysis

Vibration analysis is a powerful tool for identifying mechanical issues within a gearbox. By analyzing vibration patterns, technicians can detect imbalances, misalignments, and bearing failures. Early detection of these issues can prevent catastrophic failures and extend the gearbox’s lifespan.

Temperature Monitoring

Monitoring the temperature of a gearbox is crucial for preventing overheating, which can lead to significant damage. Advanced temperature sensors can provide continuous data, alerting operators to abnormal temperature rises. This allows for immediate corrective actions, such as adjusting the load or improving ventilation.

Conclusion

Extending the life of industrial gearboxes requires a comprehensive approach that includes regular maintenance, optimized lubrication practices, and the implementation of advanced monitoring systems. By adhering to these best practices, operators can enhance the reliability and efficiency of their machinery, ultimately reducing downtime and operational costs. Investing in the longevity of gearboxes not only benefits the equipment but also contributes to the overall success of industrial operations.