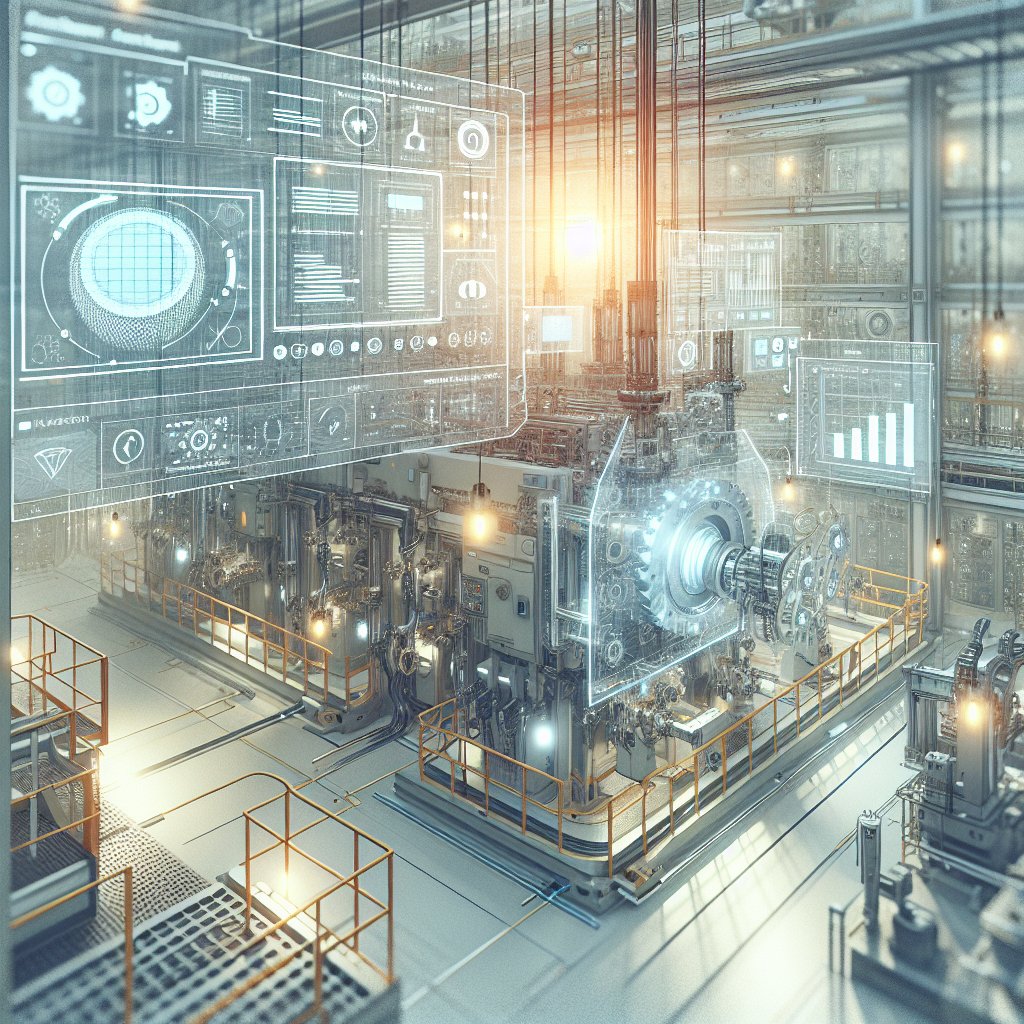

Predictive analytics is revolutionizing the industrial sector by providing a data-driven approach to maintenance, enabling companies to anticipate equipment failures and optimize operational efficiency. This innovative approach leverages vast amounts of data collected from machinery and processes to predict potential issues before they occur, thus minimizing downtime and reducing maintenance costs. In this article, we will explore the fundamentals of predictive analytics in the industrial sector, its benefits, and how it is transforming maintenance strategies.

Understanding Predictive Analytics

Predictive analytics involves the use of statistical algorithms and machine learning techniques to analyze historical and real-time data, with the goal of making predictions about future events. In the industrial sector, this means using data from sensors, equipment logs, and other sources to forecast when a machine might fail or require maintenance. By identifying patterns and trends in the data, predictive analytics can provide valuable insights that help companies make informed decisions about their maintenance strategies.

The Role of Data in Predictive Analytics

Data is the backbone of predictive analytics. In the industrial sector, data is collected from a variety of sources, including sensors embedded in machinery, production logs, and environmental data. This data is then processed and analyzed to identify patterns and trends that can indicate potential issues. The quality and quantity of data are crucial for the accuracy of predictive models, making data management and integration key components of a successful predictive analytics strategy.

Machine Learning and Predictive Models

Machine learning plays a critical role in predictive analytics by enabling the development of predictive models that can learn from data and improve over time. These models use algorithms to analyze data and identify patterns that can predict future outcomes. In the industrial sector, machine learning models can be used to predict equipment failures, optimize maintenance schedules, and improve overall operational efficiency. By continuously learning from new data, these models become more accurate and reliable, providing companies with valuable insights that can drive better decision-making.

Benefits of Predictive Analytics in Maintenance

The adoption of predictive analytics in the industrial sector offers numerous benefits, particularly in the area of maintenance. By leveraging data-driven insights, companies can move from reactive to proactive maintenance strategies, resulting in significant cost savings and improved operational efficiency.

Reducing Downtime and Maintenance Costs

One of the primary benefits of predictive analytics is its ability to reduce downtime and maintenance costs. By predicting equipment failures before they occur, companies can schedule maintenance activities at the most convenient times, minimizing disruptions to production. This proactive approach not only reduces the frequency and duration of downtime but also extends the lifespan of equipment, leading to significant cost savings over time.

Improving Operational Efficiency

Predictive analytics also enhances operational efficiency by optimizing maintenance schedules and resource allocation. By identifying the most critical maintenance tasks and prioritizing them accordingly, companies can ensure that their resources are used effectively. This leads to improved productivity and efficiency, as well as a more streamlined maintenance process. Additionally, predictive analytics can help companies identify areas for improvement in their operations, leading to further efficiency gains.

Enhancing Safety and Compliance

Safety and compliance are critical concerns in the industrial sector, and predictive analytics can play a key role in addressing these issues. By predicting potential equipment failures and maintenance needs, companies can take proactive measures to prevent accidents and ensure compliance with safety regulations. This not only protects employees and assets but also helps companies avoid costly fines and legal issues associated with non-compliance.

Implementing Predictive Analytics in the Industrial Sector

Implementing predictive analytics in the industrial sector requires a strategic approach that involves several key steps. From data collection and integration to model development and deployment, companies must carefully plan and execute their predictive analytics initiatives to achieve the desired outcomes.

Data Collection and Integration

The first step in implementing predictive analytics is to collect and integrate data from various sources. This involves identifying the relevant data sources, such as sensors, equipment logs, and production data, and ensuring that the data is accurate and complete. Data integration is also crucial, as it allows companies to combine data from different sources and create a comprehensive view of their operations. This provides the foundation for building accurate and reliable predictive models.

Developing Predictive Models

Once the data is collected and integrated, the next step is to develop predictive models that can analyze the data and make accurate predictions. This involves selecting the appropriate machine learning algorithms and training the models using historical data. The models must be continuously updated and refined as new data becomes available, ensuring that they remain accurate and reliable over time. Companies may also need to collaborate with data scientists and other experts to develop and implement their predictive models effectively.

Deploying and Monitoring Predictive Analytics Solutions

After the predictive models are developed, they must be deployed and integrated into the company’s existing systems and processes. This involves setting up the necessary infrastructure and tools to support the deployment and monitoring of the predictive analytics solutions. Companies must also establish processes for monitoring the performance of the models and making adjustments as needed. This ensures that the predictive analytics solutions continue to deliver accurate and valuable insights that drive better decision-making.

Challenges and Considerations

While predictive analytics offers significant benefits, there are also challenges and considerations that companies must address when implementing these solutions. From data quality and integration issues to the need for skilled personnel, companies must navigate a range of challenges to successfully implement predictive analytics in their operations.

Data Quality and Integration

Data quality and integration are critical challenges in predictive analytics. Inaccurate or incomplete data can lead to unreliable predictions, while data integration issues can prevent companies from creating a comprehensive view of their operations. To address these challenges, companies must invest in data management and integration solutions that ensure data accuracy and completeness. This may involve implementing data cleansing and validation processes, as well as integrating data from different sources into a unified platform.

Skilled Personnel and Expertise

Implementing predictive analytics requires skilled personnel with expertise in data science, machine learning, and analytics. Companies may need to hire or train employees with the necessary skills to develop and manage predictive models effectively. Additionally, collaboration with external experts and consultants may be necessary to ensure the success of predictive analytics initiatives. Investing in training and development programs can help companies build the necessary expertise and capabilities to leverage predictive analytics effectively.

Change Management and Adoption

Adopting predictive analytics requires a cultural shift within the organization, as employees must embrace new technologies and processes. Change management is crucial to ensure that employees understand the benefits of predictive analytics and are willing to adopt new ways of working. This may involve providing training and support to employees, as well as communicating the value of predictive analytics to stakeholders. By fostering a culture of innovation and continuous improvement, companies can successfully integrate predictive analytics into their operations and drive better outcomes.

The Future of Predictive Analytics in the Industrial Sector

As technology continues to evolve, the future of predictive analytics in the industrial sector looks promising. Advances in machine learning, artificial intelligence, and data analytics are expected to further enhance the capabilities of predictive analytics, enabling companies to achieve even greater levels of efficiency and performance.

Integration with IoT and Industry 4.0

The integration of predictive analytics with the Internet of Things (IoT) and Industry 4.0 technologies is expected to drive significant advancements in the industrial sector. IoT devices and sensors provide a wealth of real-time data that can be used to enhance predictive models and improve decision-making. By combining predictive analytics with IoT and Industry 4.0 technologies, companies can create smart factories that are capable of self-optimizing and adapting to changing conditions. This will lead to increased efficiency, reduced costs, and improved competitiveness in the global market.

Advancements in Machine Learning and AI

Advancements in machine learning and artificial intelligence are expected to further enhance the capabilities of predictive analytics. New algorithms and techniques are being developed that can analyze larger and more complex datasets, leading to more accurate and reliable predictions. Additionally, AI-powered predictive analytics solutions can automate decision-making processes, allowing companies to respond more quickly to changing conditions and opportunities. As these technologies continue to evolve, companies will be able to leverage predictive analytics to achieve even greater levels of efficiency and performance.

Increased Focus on Sustainability

Sustainability is becoming an increasingly important consideration for companies in the industrial sector, and predictive analytics can play a key role in supporting sustainability initiatives. By optimizing maintenance schedules and resource allocation, predictive analytics can help companies reduce waste and energy consumption, leading to more sustainable operations. Additionally, predictive analytics can support the development of sustainable products and processes by providing insights into the environmental impact of different options. As companies continue to prioritize sustainability, predictive analytics will become an essential tool for achieving their goals.

In conclusion, predictive analytics is transforming the industrial sector by providing a data-driven approach to maintenance that enhances efficiency, reduces costs, and improves safety. By leveraging the power of data and advanced analytics, companies can move from reactive to proactive maintenance strategies, leading to significant benefits and competitive advantages. As technology continues to evolve, the potential of predictive analytics in the industrial sector is vast, offering exciting opportunities for innovation and growth.