Industrial HVAC systems are the backbone of climate control in large-scale facilities, ensuring optimal working conditions and energy efficiency. Regular maintenance of these systems is crucial to prevent breakdowns, extend their lifespan, and maintain air quality. This article delves into the significance of routine upkeep for industrial HVAC systems, exploring the benefits and best practices for maintaining these complex systems.

Understanding Industrial HVAC Systems

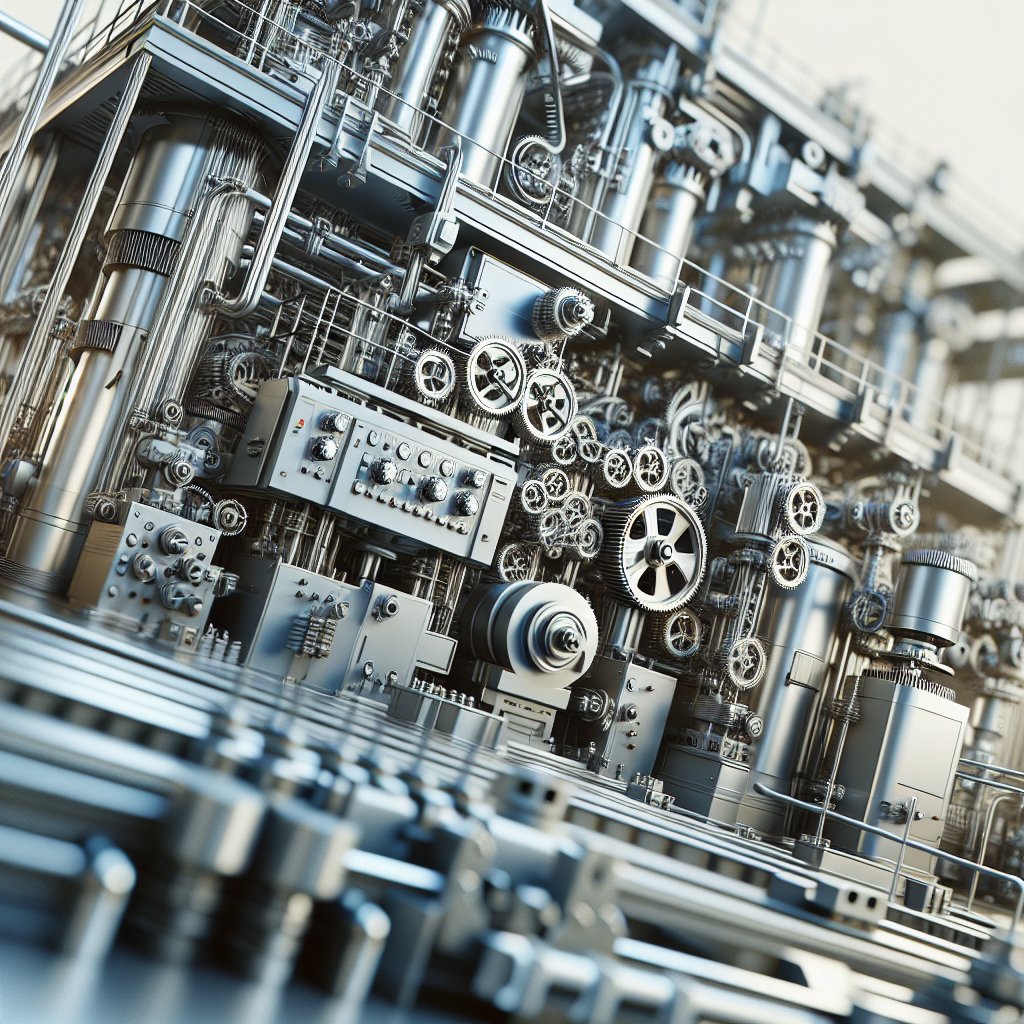

Industrial HVAC (Heating, Ventilation, and Air Conditioning) systems are designed to regulate the environmental conditions within large buildings such as factories, warehouses, and office complexes. Unlike residential systems, industrial HVAC units are more complex and robust, tailored to handle larger spaces and more demanding conditions. These systems are responsible for maintaining temperature, humidity, and air quality, which are critical for both human comfort and the proper functioning of machinery and equipment.

The components of an industrial HVAC system typically include air handlers, chillers, boilers, cooling towers, and ductwork. Each component plays a vital role in the overall operation of the system, and any malfunction can lead to significant disruptions. Therefore, understanding the intricacies of these systems is essential for effective maintenance and operation.

The Benefits of Regular Maintenance

Regular maintenance of industrial HVAC systems offers numerous benefits that can significantly impact the efficiency and longevity of the equipment. Here are some key advantages:

- Improved Energy Efficiency: Well-maintained HVAC systems operate more efficiently, reducing energy consumption and lowering utility bills. Regular cleaning and servicing of components such as filters, coils, and fans ensure that the system runs smoothly without unnecessary strain.

- Extended Equipment Lifespan: Routine maintenance helps identify and address potential issues before they escalate into major problems. By replacing worn-out parts and making necessary adjustments, the lifespan of the HVAC system can be significantly extended, delaying the need for costly replacements.

- Enhanced Air Quality: Industrial environments can accumulate dust, pollutants, and other airborne particles. Regular maintenance, including cleaning and replacing air filters, ensures that the air circulated within the facility is clean and healthy, reducing the risk of respiratory issues for employees.

- Reduced Downtime: Unexpected breakdowns can lead to costly downtime and disruptions in operations. Scheduled maintenance helps prevent sudden failures, allowing businesses to plan and manage their operations more effectively.

- Compliance with Regulations: Many industries are subject to strict regulations regarding air quality and environmental standards. Regular maintenance ensures that HVAC systems comply with these regulations, avoiding potential fines and legal issues.

Best Practices for HVAC Maintenance

To maximize the benefits of regular maintenance, it is essential to follow best practices tailored to the specific needs of industrial HVAC systems. Here are some recommended practices:

Develop a Maintenance Schedule

Creating a comprehensive maintenance schedule is the first step in ensuring regular upkeep of HVAC systems. This schedule should outline routine inspections, cleaning, and servicing tasks, as well as the frequency at which they should be performed. Depending on the system’s complexity and usage, maintenance tasks may be required monthly, quarterly, or annually.

Conduct Regular Inspections

Regular inspections are crucial for identifying potential issues before they become major problems. During inspections, technicians should check for signs of wear and tear, leaks, unusual noises, and other indicators of malfunction. Early detection allows for timely repairs and prevents costly breakdowns.

Clean and Replace Filters

Air filters play a vital role in maintaining air quality and system efficiency. Over time, filters can become clogged with dust and debris, reducing airflow and forcing the system to work harder. Regular cleaning and replacement of filters are essential to ensure optimal performance and air quality.

Check and Calibrate Thermostats

Thermostats control the temperature settings of HVAC systems. Regularly checking and calibrating thermostats ensures that they provide accurate readings and maintain the desired temperature levels. Faulty thermostats can lead to energy wastage and discomfort for occupants.

Inspect and Clean Coils

Coils are responsible for heat exchange in HVAC systems. Over time, they can accumulate dirt and grime, reducing their efficiency. Regular cleaning of coils is necessary to maintain optimal heat transfer and prevent system strain.

Monitor Refrigerant Levels

Refrigerant is a critical component of cooling systems. Low refrigerant levels can lead to reduced cooling capacity and increased energy consumption. Regularly monitoring and adjusting refrigerant levels ensures that the system operates efficiently and effectively.

Conclusion

Regular maintenance of industrial HVAC systems is not just a matter of convenience; it is a necessity for ensuring efficient operation, cost savings, and compliance with regulations. By understanding the components and benefits of these systems and following best practices for maintenance, businesses can optimize their HVAC systems’ performance and longevity. Investing in routine upkeep ultimately leads to a healthier, more productive environment and a more sustainable operation.