The aerospace sector relies on some of the most sophisticated equipment ever conceived by humankind. From ground support gear that demands unparalleled precision to airborne propulsion units that generate immense power, every machine plays a critical role in taking flight. This article delves into several categories of advanced machinery at work in the aerospace industry, revealing how these systems combine cutting-edge technology with rigorous processes to ensure ultimate performance and safety.

Advanced Propulsion Systems

Propulsion remains the heartbeat of aerospace technology. Modern aircraft and spacecraft employ a variety of thrust-generating machines, each designed to meet stringent requirements for efficiency, reliability, and environmental compliance. Key components include:

- Jet engine cores, where fuel combustion powers high-speed turbines

- Afterburners that inject additional fuel downstream for bursts of thrust

- Rocket engines using cryogenic or hypergolic propellants to escape Earth’s gravity

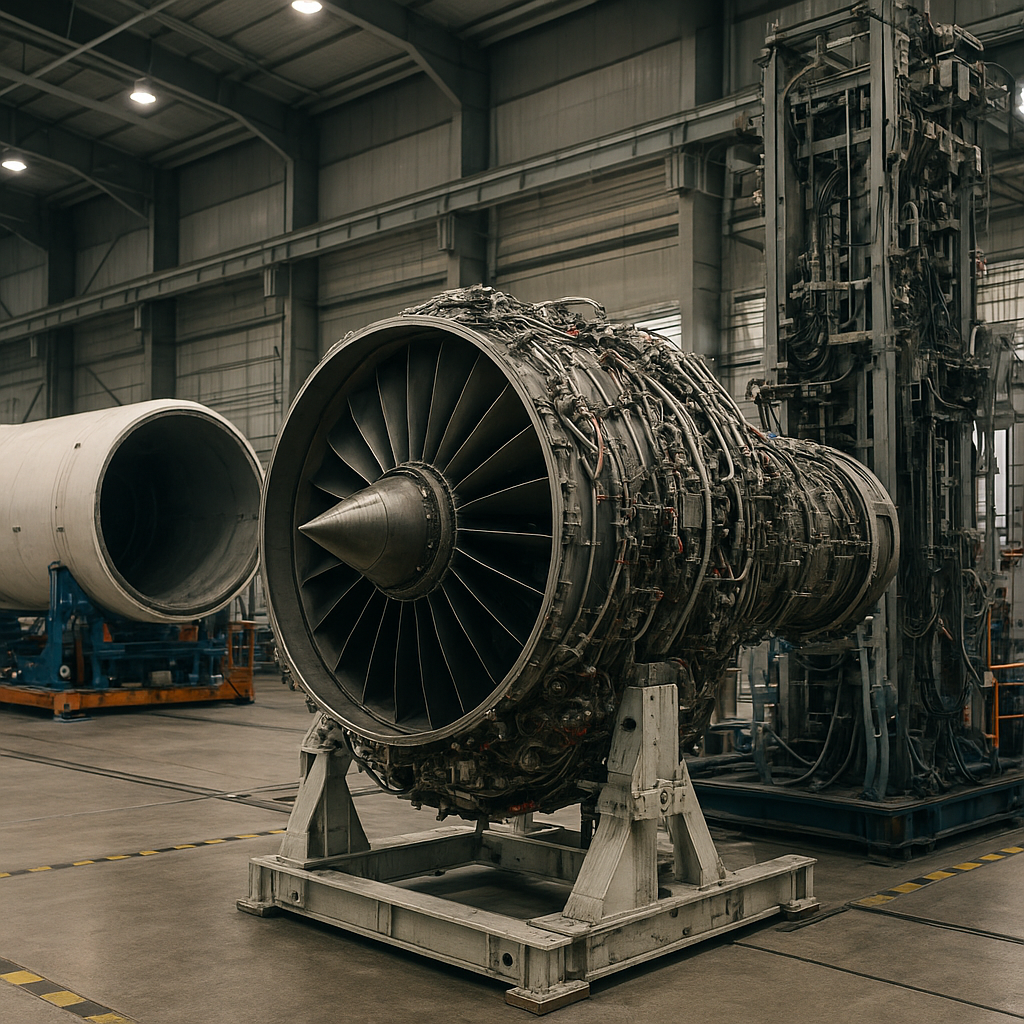

Jet Engine Testing Cells

In dedicated test cells, engineers examine full-scale turbine assemblies under extreme conditions. These facilities replicate altitudes up to 60,000 feet and temperatures exceeding 1,600°C. Data acquisition systems capture vibration signatures, pressure fluctuations, and emissions. Such exhaustive testing validates computational models and ensures compliance with global standards.

Next-Generation Propulsion Concepts

Advanced Turbine Cooling techniques use ceramic matrix composites and internal cooling passages to allow hotter combustion, driving higher efficiency. Meanwhile, electric-boosted fans and hybrid-electric thrust pods are under development to reduce carbon footprints. These innovations herald a new era in quieter, cleaner flight.

Composite Material Fabrication

The transition from metallic alloys to high-performance composites has revolutionized aerospace structures. Automated fabrication lines produce wing skins, fuselage sections, and payload fairings with unmatched strength-to-weight ratios. The core processes include:

- Automated Fiber Placement (AFP) to lay down carbon tapes in precise orientations

- Resin Transfer Molding (RTM) for rapid infusion of advanced polymers

- Autoclave curing cycles that apply uniform pressure and heat

Autoclaves and Cure Cycles

Large-scale autoclaves—some exceeding 20 meters in length—subject composite layups to pressures above 7 bar and temperatures beyond 180°C. The process eliminates voids and ensures uniform resin distribution. Computer-controlled ramps and dwells maintain exact thermal profiles for each composite recipe.

Quality Monitoring in Real Time

Inline sensors measure resin flow, fiber orientation, and temperature gradients. Any deviation triggers automated adjustments or rejects the part. This closed-loop control guarantees that every panel meets tolerance windows of fractions of a millimeter.

Robotic Assembly and Inspection

High-volume production and intricate assemblies demand industrial machines capable of flawless repetition. Robotics in aerospace have advanced to handle everything from fastening thousands of rivets to performing nondestructive evaluation. Prominent applications include:

- robotics-driven drilling and countersinking to avoid human error

- Collaborative arms that assist technicians in installing heavy avionics racks

- Automated Eddy-Current and ultrasonic probes for structural inspection

Collaborative Robots on the Shop Floor

Designed to work alongside engineers, these cobots feature force sensing and compliance modes. They can lift large composite panels or hold torque tools, dramatically reducing cycle times. Integrated vision systems allow them to identify parts and adjust trajectories in real time.

Drone-Based Airframe Surveys

Small unmanned aerial vehicles map the exterior of aircraft during maintenance checks. Equipped with high-resolution cameras and infrared sensors, they detect surface cracks, delaminations, and paint irregularities faster than manual inspectors. Software stitches thousands of images into a 3D model for detailed analysis.

Automation and Quality Assurance

To maintain the highest safety levels, aerospace manufacturers employ an interconnected network of machines for end-to-end manufacturing oversight. From initial CAD designs to final acceptance tests, digital tools and hardware converge to optimize every step.

- Model-based definition systems that use 3D geometry instead of 2D drawings

- automation platforms tying CAM routines, robots, and inspection stations

- Digital twin simulations of assembly lines to predict bottlenecks

Digital Twins and Predictive Maintenance

A digital twin is a virtual replica of physical machinery, fed by sensor data from real components. Analytics engines monitor wear patterns, temperature trends, and cycle counts. When a critical threshold is approached, maintenance is scheduled before failure occurs. This approach reduces unplanned downtime and extends equipment life.

High-Fidelity Wind Tunnel Testing

Wind tunnels equipped with sensitive load cells and laser-based flow visualization evaluate aerodynamics on scale models and full-size prototypes. Automated turntables and force balances measure lift, drag, and moments across flight envelopes. Specialized fans and flow straighteners ensure laminar conditions for accurate data.

Space Systems and Specialized Test Rigs

Beyond aircraft, space-bound hardware encounters its own machineries. Satellite integration facilities, vacuum chambers, and vibration shakers stand among the most complex installations dedicated to mission-critical components.

Environmental Simulation Chambers

Vacuum chambers simulate the hard vacuum and radiation environment of orbit. Thermal shrouds cycle between –150°C and +150°C to stress materials and electronics. These chambers are often paired with acoustic enclosures to reproduce rocket launch sound levels exceeding 140 decibels.

Seismic and Random Vibration Tables

Payloads destined for the ISS or interplanetary missions must survive intense vibrations during liftoff. Multi-axis shakers deliver programmed profiles matching each launch vehicle. Teams monitor accelerometers and strain gauges to capture real-time structural data.

Emerging Trends and Future Machines

As demand for global connectivity and rapid logistics grows, the next generation of aerospace equipment will include hypersonic test tracks, autonomous ground vehicles, and AI-driven decision support systems. Additive manufacturing centers capable of producing faultless metal turbine blades and in-orbit robotic servicing platforms will further push the boundaries of what machines can achieve at aerospace’s cutting edge.