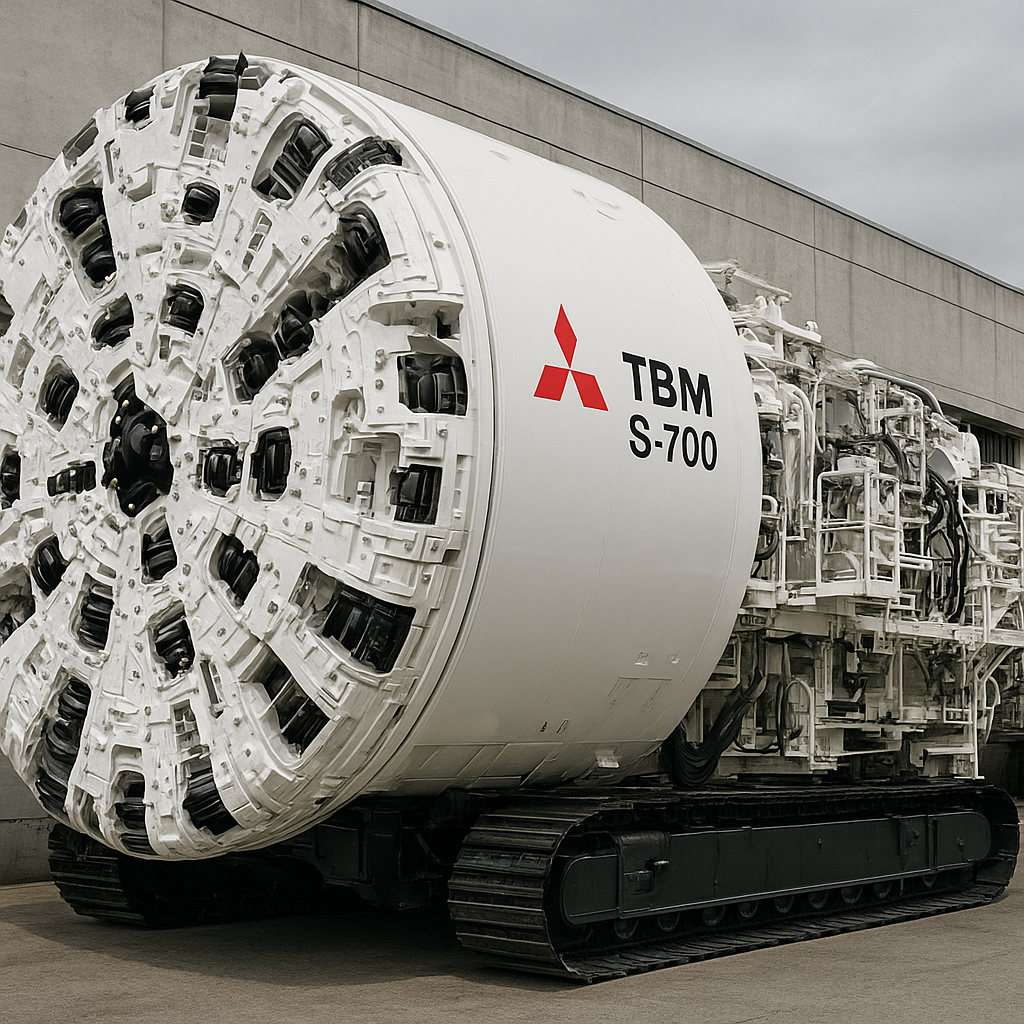

The Mitsubishi TBM S-700 is a modern tunnel boring machine designed to meet the complex demands of contemporary underground construction. Combining robust mechanical components with advanced control and monitoring systems, machines in the S-series from Mitsubishi Heavy Industries are engineered to deliver reliable, efficient excavation across a wide range of ground conditions. This article reviews the design principles, typical applications, operational characteristics, and practical considerations related to the S-700, as well as the broader context of TBM use in urban infrastructure and civil engineering projects.

Design and technical features

The S-700 embodies the core technologies that characterise Mitsubishi’s shield-type TBMs: a reinforced cutterhead and shield, modular segment erector and conveyor systems, and integrated hydraulics and electrical platforms. While specific configurations vary according to project requirements—such as diameter, ground type, and lining method—the S-700 platform emphasises adaptability and maintainability.

Key technical elements

- Cutterhead and cutting tools: The cutterhead is designed to accept a range of cutting tools and disc cutters suitable for hard rock, mixed face, or soft ground. Configurations may include open-type heads for rock, and more protected profiles for EPB (Earth Pressure Balance) or slurry applications.

- Shield and conveyor: A robust shield protects the working face and the trailing support systems. Internal conveyor belts or screw conveyors remove spoil continuously, optimised for either mucking via conveyor or slurry pumping in slurry-type setups.

- Thrust and torque systems: High-capacity hydraulic thrust cylinders and a powerful drive train deliver the axial force and rotational torque necessary to advance the machine and break rock or soil. These systems are sized to match the machine’s diameter and ground conditions.

- Segment handling and lining installation: Many S-700 setups include an automated segment erector that places pre-cast concrete rings directly behind the cutterhead, ensuring rapid lining installation and minimising auxiliary labour needs.

- Instrumentation and control: Real-time monitoring, geotechnical instrumentation, and automated control systems permit precise management of face pressure, advance rate, torque, and tool wear indicators. These control systems are essential for safe operation in urban environments with shallow cover or mixed geology.

- Modularity: The TBM is designed to be assembled and disassembled in sections at the launch and retrieval shafts, enabling transport to constrained urban sites and allowing the machine to be configured for either open, pressurised or slurry operation.

Typical applications and project types

Mitsubishi TBMs like the S-700 are most often used where mechanised tunnelling offers significant advantages over conventional excavation methods. They are particularly suited for projects demanding reduced surface disruption, predictable progress, and consistent lining quality.

Metro and urban rail tunnels

Urban transit expansions often require tunnelling beneath densely built environments, where ground settlement, noise, and vibration must be strictly controlled. The S-700’s capacity for pressure control and precise instrumentation make it suitable for constructing metro tunnels, cross passages, and station approaches while minimising impact on surface structures and utilities.

Road and highway tunnels

For road tunnels, long single-bore or twin-bore alignments benefit from the speed and reliability of TBM-driven excavation. The S-700 can be configured to install full concrete rings or tunnel linings that meet structural and fire-safety requirements for vehicular tunnels.

Water, sewer and utility tunnels

Projects such as large-diameter sewer conveyance, raw water transfer tunnels, and utility diversions frequently use TBMs to achieve continuous excavation and lining installation. The controlled environment created by shielded TBMs is ideal for ensuring watertight linings and reduced inflows in pressurised aquifers.

Mixed-face and challenging geology

Where tunnels encounter alternating sections of rock, soil, cobbles, or water-bearing strata, the S-700’s flexibility—especially when equipped for EPB or slurry operation—permits continuous excavation without frequent method changes. This reduces schedule risk and logistical complexity.

Operational performance and typical statistics

Performance of any TBM, including the S-700, depends on geology, alignment complexity, logistical support, and the configuration of the machine. Rather than a single fixed set of figures, operational statistics are best understood as ranges and performance benchmarks used by tunnelling contractors and clients during planning.

Production and advance rates

- Average daily advance in favourable soft ground with an EPB setup: typically 10–30 metres per day. Peak daily advances under ideal conditions can exceed 40–50 metres, but these are exceptional and depend on long runs of homogeneous ground.

- Average daily advance in good rock conditions with a shielded hard-rock TBM: often 5–20 metres per day depending on rock strength, fracture frequency, and cutter wear.

- Monthly and yearly production figures are project-specific: some long drives achieve several kilometres within a year, while complex metropolitan projects may progress more slowly due to urban constraints and frequent maintenance.

Power, thrust and dimensions

- Installed electrical motor power for medium-to-large TBMs can range from several hundred kilowatts to multiple megawatts. The exact power rating for an S-700 configuration will be selected to match cutterhead torque and drum speed requirements.

- Thrust forces and torque values scale with cutterhead diameter. For medium diameters common in metro and utility tunnels, hydraulic thrust systems commonly deliver thousands to tens of thousands of kilonewtons of axial force and torques in the range of tens to hundreds of kilonewton-metres.

- Machine weight and length depend on diameter and trailing gear. Typical shielded TBMs are assembled from multiple segments and can extend hundreds of metres when the full trailing support including conveyors and backup systems are counted.

Tool life and maintenance

- Tooling wear rates depend heavily on geology. Disc cutters operating in abrasive or highly fractured rock may require frequent replacement, while soft ground conditions see less cutter wear but higher demands on sealing components and screw conveyors.

- Planned maintenance intervals, cutter change-outs, and overhauls are scheduled based on runtime hours, penetration performance, and instrumentation feedback. Predictive maintenance supported by real-time monitoring reduces unscheduled downtime.

Where available, OEM and contractor data for specific S-700 deployments provide more precise metrics. However, those figures are typically reported per project because TBM configurations are highly customised.

Advantages, limitations and environmental aspects

TBMs such as the S-700 offer clear advantages in many tunnelling contexts, but they also present limitations that must be managed during planning and execution.

Advantages

- Reduced surface disruption: Minimal open excavation reduces impact on traffic, businesses and residents—critical in urban projects.

- Continuous automated lining: Automated segment installation improves quality control, increases safety, and shortens construction windows.

- Predictability: Once a TBM is performing in consistent ground, daily progress can be reasonably forecasted, assisting schedule and cost control.

- Safety: Operators work within the shield, protected from the face and ground collapse, reducing exposure to hazards common in drill-and-blast or cut-and-cover methods.

Limitations and challenges

- High mobilisation costs: TBMs require specialised assembly, launch shafts and significant logistical planning. This makes short tunnels or small-diameter bores less economical for TBM use.

- Geotechnical risk: Highly variable ground, unexpected cobbles or voids, and water inflows can complicate progress and require contingency measures such as ground improvement or grout injection.

- Maintenance and tooling: Tool wear and the need for cutter changes can interrupt production; effective planning is required to minimise downtime.

Environmental and community considerations

- TBMs reduce noise and dust compared with open excavation, and when combined with careful spoil management, they decrease surface environmental impact.

- Managing groundwater inflows, disposal of contaminated spoil, and surface settlement monitoring are integral to projects employing TBMs in urban settings.

Operational best practices and risk mitigation

Success with an S-700 deployment depends on integrating machine capability with comprehensive planning, site logistics, and geotechnical investigation.

- Pre-construction geotechnical investigation: Dense borehole coverage, geophysics, and laboratory testing reduce surprises and aid in selecting EPB vs slurry configurations, cutter types, and segment design.

- Instrumentation and monitoring: Real-time monitoring of face pressure, torque, thrust, settlement at the surface and in adjacent structures, and groundwater levels enables rapid response to anomalies.

- Contingency planning: Preparing for ground improvement, intermediate grouting, or temporary dewatering reduces schedule risk when unexpected conditions arise.

- Logistics and supply chain: A reliable supply of pre-cast segments, spare cutters, hydraulic parts and trained maintenance teams is essential for minimising downtime.

- Skilled workforce and training: Operators and engineers trained in TBM systems and contingency procedures significantly improve operational resilience.

Case studies and examples of use

Although projects using specific Mitsubishi TBM models such as the S-700 vary widely in scale and context, the general profile of successful deployments includes metro expansions, cross-city utility diversions, and long bore highway tunnels. A few typical project archetypes include:

- Long urban rail tunnels where a TBM minimizes disruption and provides continuous lined tunnel sections for rolling stock and station interfaces.

- Water transfer tunnels that must maintain low settlement and high lining watertightness under variable geological and hydrogeological conditions.

- Utility diversions beneath congested urban corridors where open excavation would be impractical or impossible.

In each case, Mitsubishi’s engineering support includes pre-construction studies, machine customisation, and operational support to integrate the TBM into the contractor’s project plan.

Maintenance, lifecycle and upgrades

The lifecycle of a TBM like the S-700 extends beyond a single drive. With appropriate refurbishment, a TBM can be reconfigured and redeployed on subsequent projects—making long-term asset management an important consideration for owners and contractors.

Maintenance strategy

- Planned preventative maintenance during scheduled breaks reduces the probability of catastrophic failures.

- Condition-based and predictive maintenance enabled by sensors and analytics allow targeted interventions that save time and cost.

- Major overhauls—such as replacing the cutterhead, renewing hydraulic systems, or structural repairs—are typically performed after a certain runtime threshold or after particularly abrasive projects.

Reconfiguration and resale

- Modular design allows reconfiguration from EPB to slurry systems or adaptation to different diameters within certain limits. This flexibility increases the residual value of the machine.

- After refurbishment, machines can be sold on the secondary market or leased to contractors, spreading the cost across multiple projects.

Technological trends and future directions

Tunnelling technology evolves continuously, and modern TBMs increasingly integrate digital tools and automation to improve performance and safety.

- Automation: Automated segment erection, predictive control of face pressure and advance rate, and more autonomous decision-support systems reduce human error and improve throughput.

- Digital twins and data analytics: Creating a digital twin of the TBM and the tunnel drive allows simulation of different scenarios, predictive maintenance and optimisation of advance rates.

- Advanced cutting materials: New alloys and tool geometries extend cutter life in abrasive conditions, reducing downtime and improving overall productivity.

- Sustainability: Energy-efficient drives, improved spoil handling, and circular approaches to segment manufacture and reuse reflect increasing emphasis on reducing environmental footprints.

Summary and practical considerations for clients and contractors

When evaluating the Mitsubishi TBM S-700 for a project, stakeholders should weigh the machine’s adaptability, shielded operation, and automation capabilities against mobilisation costs and geotechnical risk. Detailed ground investigation, a well-structured logistics plan, and close cooperation between client, designer, TBM supplier and contractor are essential to realise the benefits of a TBM-based solution.

Key decision-making points include the drive length and tunnel diameter, ground conditions, allowable surface settlement, and the availability of shaft and launch works. When these factors align, the S-700 and similar Mitsubishi TBM platforms can deliver high-quality tunnel linings, predictable progress, and reduced surface impact—making them valuable tools for modern subterranean infrastructure development.