Servo motors have become an integral component in modern industrial equipment, offering precision, efficiency, and reliability. As industries continue to evolve, the demand for advanced machinery that can perform complex tasks with high accuracy has increased. Servo motors, with their ability to provide precise control of angular or linear position, velocity, and acceleration, are at the forefront of this technological advancement. This article delves into the various benefits of using servo motors in industrial equipment, highlighting their impact on productivity and innovation.

Understanding Servo Motors

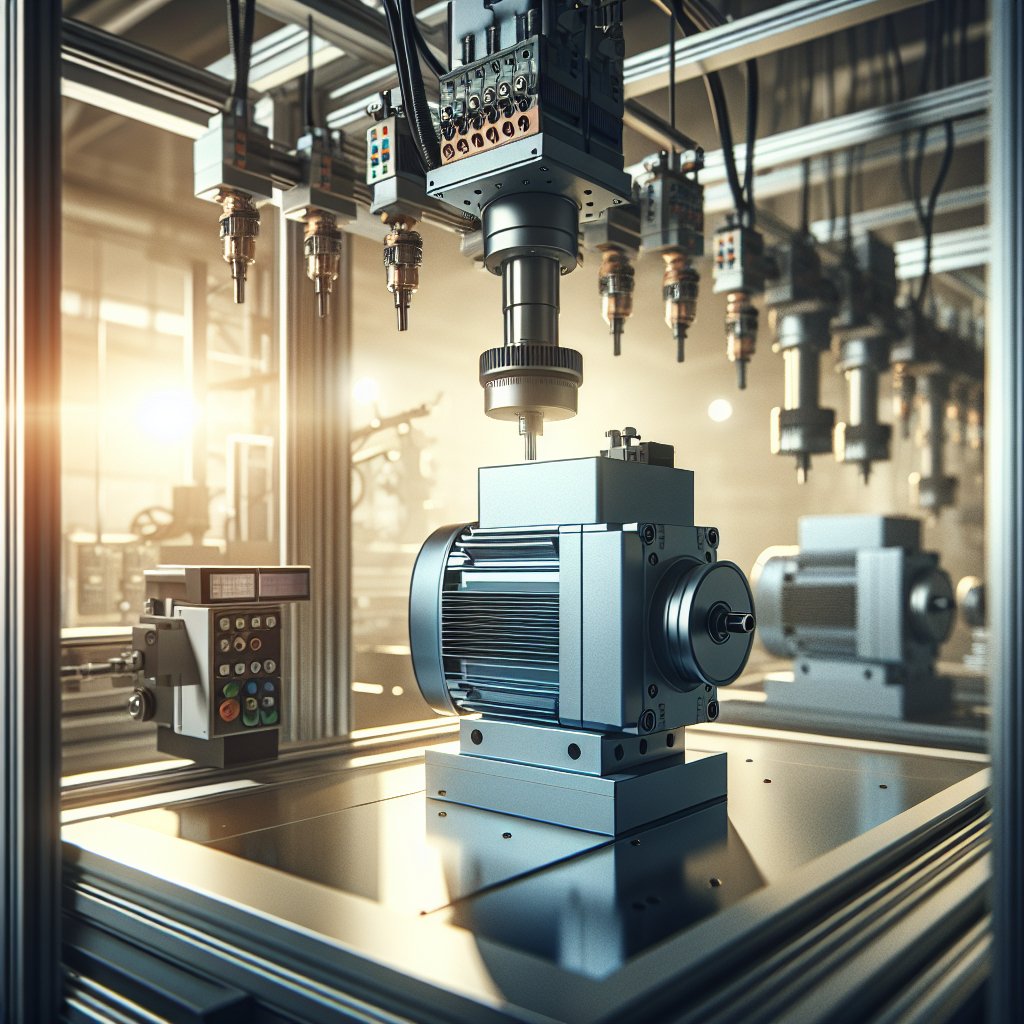

Servo motors are specialized motors designed to provide precise control over motion. Unlike traditional motors, which operate at a constant speed, servo motors can be controlled to move to a specific position, making them ideal for applications requiring high precision. They consist of a motor coupled with a sensor for position feedback, a controller, and a drive. The controller sends signals to the drive, which adjusts the motor’s position based on feedback from the sensor.

The primary advantage of servo motors is their ability to provide accurate control over motion. This is achieved through a closed-loop system, where the motor’s position is constantly monitored and adjusted to match the desired position. This level of control is essential in applications such as robotics, CNC machinery, and automated manufacturing processes, where even the slightest deviation can lead to significant errors.

Advantages of Servo Motors in Industrial Equipment

Servo motors offer numerous benefits that make them an attractive choice for industrial applications. These advantages include:

Precision and Accuracy

One of the most significant benefits of servo motors is their ability to provide precise control over motion. This precision is crucial in industries such as aerospace, automotive, and electronics, where components must be manufactured to exact specifications. Servo motors can achieve this level of accuracy by continuously monitoring and adjusting their position, ensuring that the desired outcome is achieved every time.

High Efficiency

Servo motors are known for their high efficiency, which is a critical factor in reducing energy consumption and operational costs. They can operate at high speeds with minimal energy loss, making them ideal for applications that require rapid and repetitive movements. This efficiency also translates to reduced wear and tear on the equipment, leading to longer service life and lower maintenance costs.

Flexibility and Versatility

Another advantage of servo motors is their flexibility and versatility. They can be used in a wide range of applications, from simple tasks such as conveyor belt movement to complex operations like robotic arm control. This versatility makes them a valuable asset in industries that require adaptable and multifunctional equipment.

Improved Safety

Servo motors contribute to improved safety in industrial environments. Their precise control capabilities allow for smooth and controlled movements, reducing the risk of accidents and injuries. Additionally, servo motors can be programmed to stop or reverse direction in the event of an obstruction, further enhancing safety measures.

Applications of Servo Motors in Industry

Servo motors are used in a variety of industrial applications, each benefiting from their unique capabilities. Some common applications include:

- Robotics: Servo motors are essential in robotics, providing the precise control needed for tasks such as assembly, welding, and painting. Their ability to execute complex movements with high accuracy makes them ideal for robotic arms and automated systems.

- CNC Machinery: In CNC machines, servo motors control the movement of cutting tools, ensuring that components are manufactured to exact specifications. This precision is crucial in industries such as aerospace and automotive, where even minor deviations can lead to significant issues.

- Packaging and Labeling: Servo motors are used in packaging and labeling machines to control the movement of products and labels. Their ability to operate at high speeds with precision ensures that products are packaged and labeled accurately and efficiently.

- Conveyor Systems: Servo motors are used in conveyor systems to control the speed and direction of movement. This control is essential in industries such as food and beverage, where products must be transported quickly and safely.

Conclusion

Servo motors have revolutionized the way industrial equipment operates, offering unparalleled precision, efficiency, and versatility. Their ability to provide accurate control over motion makes them an invaluable asset in a wide range of applications, from robotics to CNC machinery. As industries continue to evolve, the demand for advanced machinery that can perform complex tasks with high accuracy will only increase, further solidifying the importance of servo motors in industrial equipment.